Solar cell positive silver paste suitable for high-temperature sintering

A solar cell and silver paste technology, applied in the direction of conductive materials dispersed in non-conductive inorganic materials, etc., can solve the problems of destroying P-N junctions, low sintering yield, easy penetration of glass powder, etc., to reduce series resistance, The effect of improving the yield and improving the conversion efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~6

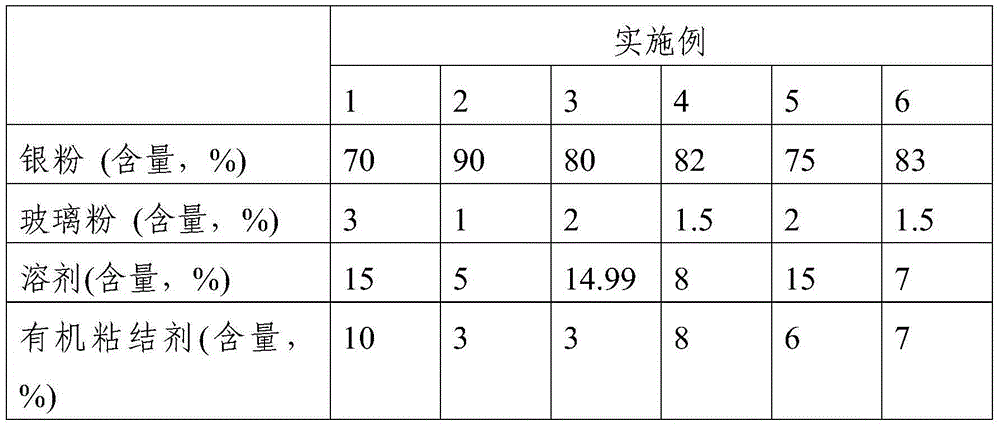

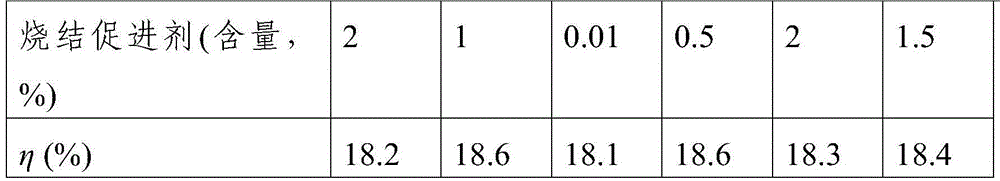

[0021] The present invention is a solar cell front silver paste suitable for high-temperature sintering. The components and weight percentages of the paste in Examples 1-6 are shown in Table 1.

[0022] In embodiment 1, silver powder is spherical, particle diameter<5 μ m; Sintering accelerator is rhodium simple substance; Described solvent is butyl carbitol or butyl carbitol acetate; Organic binder is ethyl cellulose, hydroxy Methyl cellulose or nitrocellulose; the glass powder is leaded glass powder, the softening temperature is 580-680 ℃, the particle size is <2μm, and its composition and weight percentage are: lead oxide 60%, zinc oxide 10%, aluminum oxide 5%, boric acid 5%, silicon oxide 15%, zirconium oxide 2%, and titanium oxide 3%.

[0023] In Example 2, the silver powder is spherical and has a particle size of 1 to 3 μm; the sintering accelerator is a rhodium-containing compound, preferably an oxide, chloride or sulfide of rhodium; the solvent is tributyl citrate or tr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com