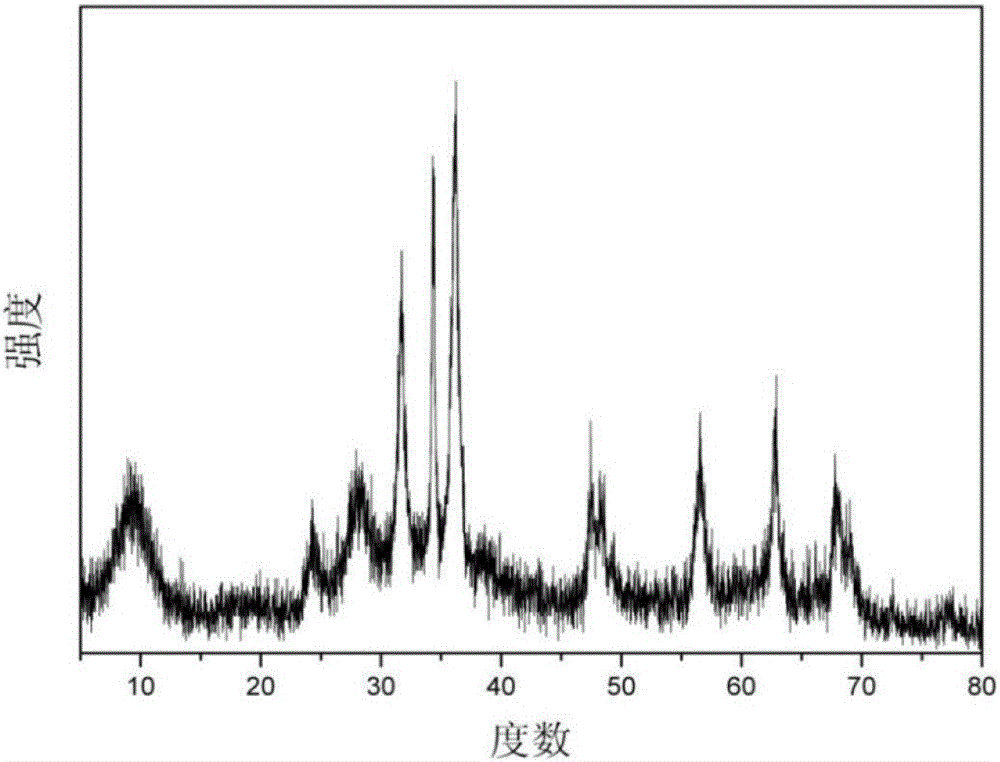

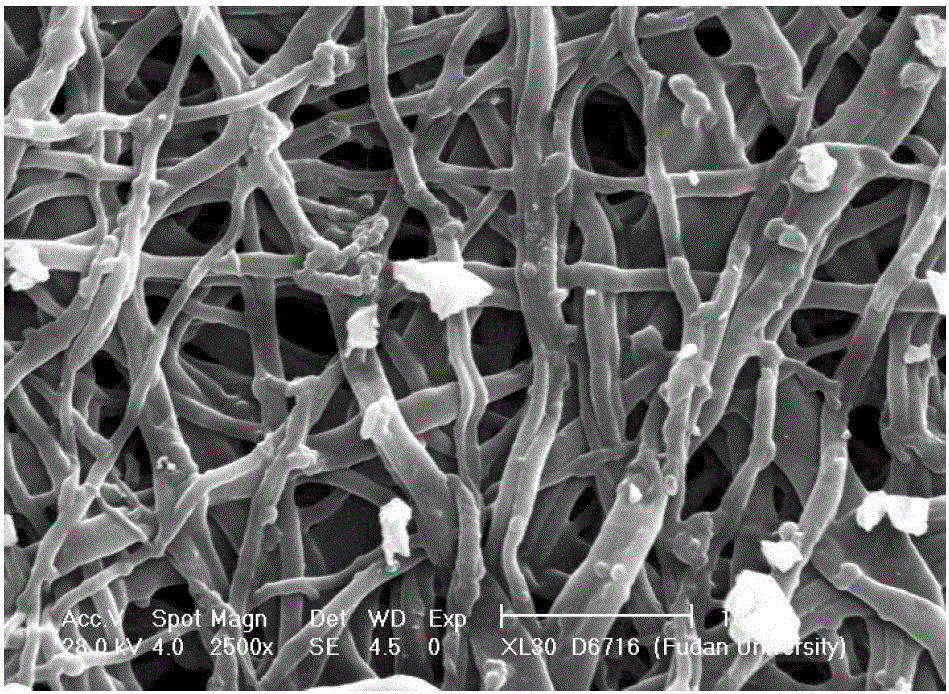

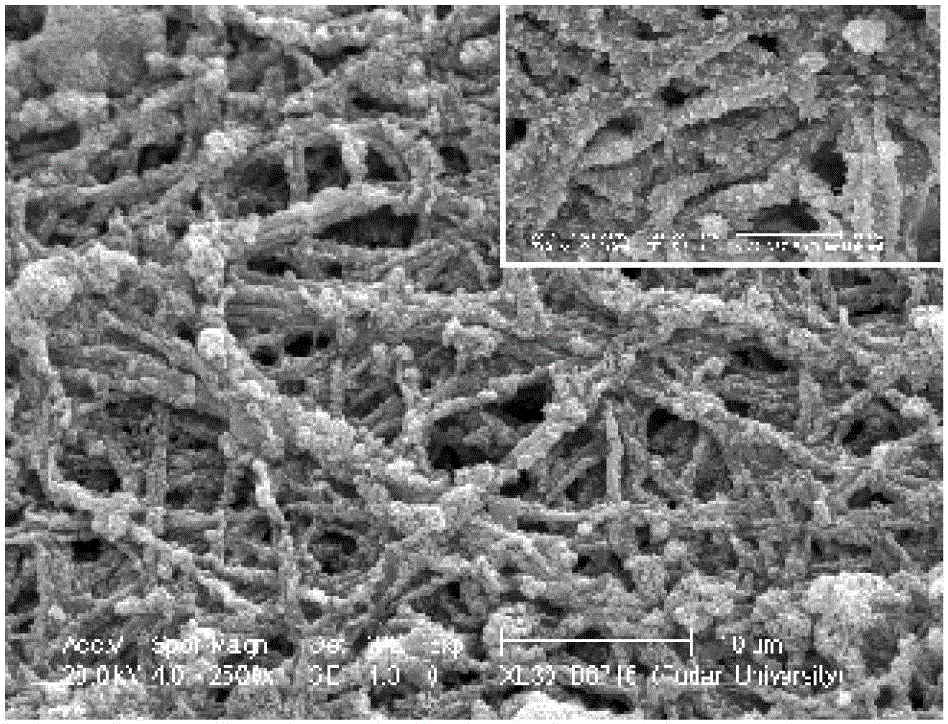

Preparation method of zinc oxide titanium dioxide nanocomposite material with network structure

A nano-composite material, titanium dioxide technology, applied in the field of preparation, can solve the problems of product morphology, uncontrollable size, easy hard agglomeration of products, affecting photocatalytic activity, etc., to achieve convenient and simple product processing, improved performance, and crystallinity Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] The present invention adopts biological template method to prepare ZnO / TiO with network structure 2 Nanocomposite photocatalytic material, the specific steps are as follows:

[0032] (1) Preparation of biological template: Wash the egg shell, peel off the outer membrane carefully, put the outer shell in an acid solution, remove the calcium carbonate shell, and the inner membrane will automatically fall off, take it out, wash it, soak it in normal saline, stand-by;

[0033] (2) Configure a certain concentration of zinc nitrate-ethanol solution (volume ratio is 1:3);

[0034] (3) Configure a certain concentration of tetra-n-butyl titanate-ethanol solution (volume ratio is 1:3);

[0035] (4) Take out the egg membrane in step (1), rinse it with distilled water, and after drying, immerse it in the solutions of steps (2) and (3) respectively, after soaking for 4 hours, take it out, and let it dry naturally;

[0036] (5) Put the dried egg film into a muffle furnace for sint...

Embodiment 2

[0039] (1) Preparation of biological template: Wash the egg shell, peel off the outer membrane carefully, put the outer shell in an acid solution, remove the calcium carbonate shell, and the inner membrane will automatically fall off, take it out, wash it, soak it in normal saline, stand-by;

[0040] (2) Configure a certain concentration of zinc acetate zinc-ethanol solution (volume ratio is 2:1);

[0041] (3) Configure a certain concentration of tetra-n-butyl titanate-ethanol solution (volume ratio is 1:3);

[0042] (4) Take out the egg membrane in step (1), rinse it with distilled water, and after drying, immerse it in the solutions of steps (2) and (3) respectively, after soaking for 4 hours, take it out, and let it dry naturally;

[0043] (5) Put the dried egg film into a muffle furnace for sintering, heat up to 550°C at 2°C / min, keep the temperature for 2h, and cool to room temperature to obtain ZnO / TiO with a network structure 2 Nanocomposite photocatalytic materials. ...

Embodiment 3

[0045] (1) Preparation of biological template: Wash the egg shell, peel off the outer membrane carefully, put the outer shell in an acid solution, remove the calcium carbonate shell, and the inner membrane will automatically fall off, take it out, wash it, soak it in normal saline, stand-by;

[0046] (2) Configure a certain concentration of zinc nitrate-ethanol solution (volume ratio is 1:1);

[0047] (3) Configure a certain concentration of titanium tetrachloride-ethanol solution (volume ratio is 1:3);

[0048] (4) Take out the egg membrane in step (1), rinse it with distilled water, and after drying, immerse it in the solutions of steps (2) and (3) respectively, after soaking for 4 hours, take it out, and let it dry naturally;

[0049] (5) Put the dried egg film into a muffle furnace for sintering, heat up to 650°C at 5°C / min, keep the temperature constant for 2 hours, and cool to room temperature to obtain ZnO / TiO with a network structure 2 Nanocomposite photocatalytic ma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com