Welding method for composite cavity sheets of high-power coupled-cavity traveling-wave tube

A welding method and composite cavity technology, applied in welding equipment, welding/welding/cutting items, non-electric welding equipment, etc., can solve problems such as slowness, surface contamination of parts, and difficulty in filling solder grooves and parts gaps with solder

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

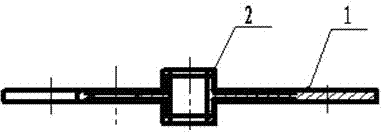

[0036] 1, a kind of welding method of the composite cavity sheet of high-power coupling cavity traveling wave tube, it is characterized in that, it comprises the following steps:

[0037] a. Cleaning of pure iron large cavity sheet (1):

[0038] The specific steps are: take the pure iron cavity sheet (1) and soak it with trichlorethylene for 30 minutes, then take it out and put it into an ultrasonic instrument and ultrasonically clean it in an alkali cleaning solution for 30 minutes, rinse it with tap water, take it out and soak it in 50% hydrochloric acid 3 minutes, after rinsing, immerse in ethanol for dehydration, and then dry it to realize the cleaning of pure iron cavity sheet (1);

[0039] b. Cleaning of the oxygen-free copper cavity ring (2):

[0040] The specific steps are: take the oxygen-free copper cavity ring (2) and put it into an ultrasonic instrument and ultrasonically clean it in an alkaline cleaning solution for 30 minutes, then take it out and polish it wit...

Embodiment 2

[0051] A welding method for a composite cavity sheet of a high-power coupling cavity traveling wave tube, comprising the following steps:

[0052] a. Cleaning of pure iron large cavity sheet (1):

[0053] The specific steps are: take the pure iron cavity sheet (1) and soak it with trichlorethylene for 60 minutes, then take it out and put it into an ultrasonic instrument and ultrasonically clean it in an alkali cleaning solution for 60 minutes, rinse it with tap water, take it out and soak it in 60% hydrochloric acid 5 minutes, after rinsing, immerse in ethanol for dehydration, and then perform drying treatment to realize the cleaning of pure iron cavity sheet (1);

[0054] b. Cleaning of the oxygen-free copper cavity ring (2):

[0055] The specific steps are: take the oxygen-free copper cavity ring (2) and put it into an ultrasonic instrument to ultrasonically clean it in an alkaline cleaning solution for 60 minutes, then take it out and polish it with a nitric acid polishin...

Embodiment 3

[0065] Embodiment 3 performance test

[0066] Take the composite cavity sheet prepared in Example 1 of the present invention and assemble the slow wave line, and then use a Varian leak detector to detect leaks on the slow wave line combination. The experimental results show that the leak rate is less than 1×10 -11 Pa.m 3 / s.

[0067] In addition, the slow wave line equipped with the composite cavity plate provided by the present invention is assembled to a high-power coupling cavity traveling wave tube. The experimental test results show that the working ratio of the coupling cavity traveling wave tube is 8%, and the pulse output power is 50kW. A very good technical effect.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com