Sulfur-containing composite microbial fertilizer and production method thereof

A technology of composite microorganisms and composite microbial agents, applied in fertilizer mixtures, fertilization devices, applications, etc., to achieve the effects of increased absorption, significant fertilizer efficiency, and environmental protection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

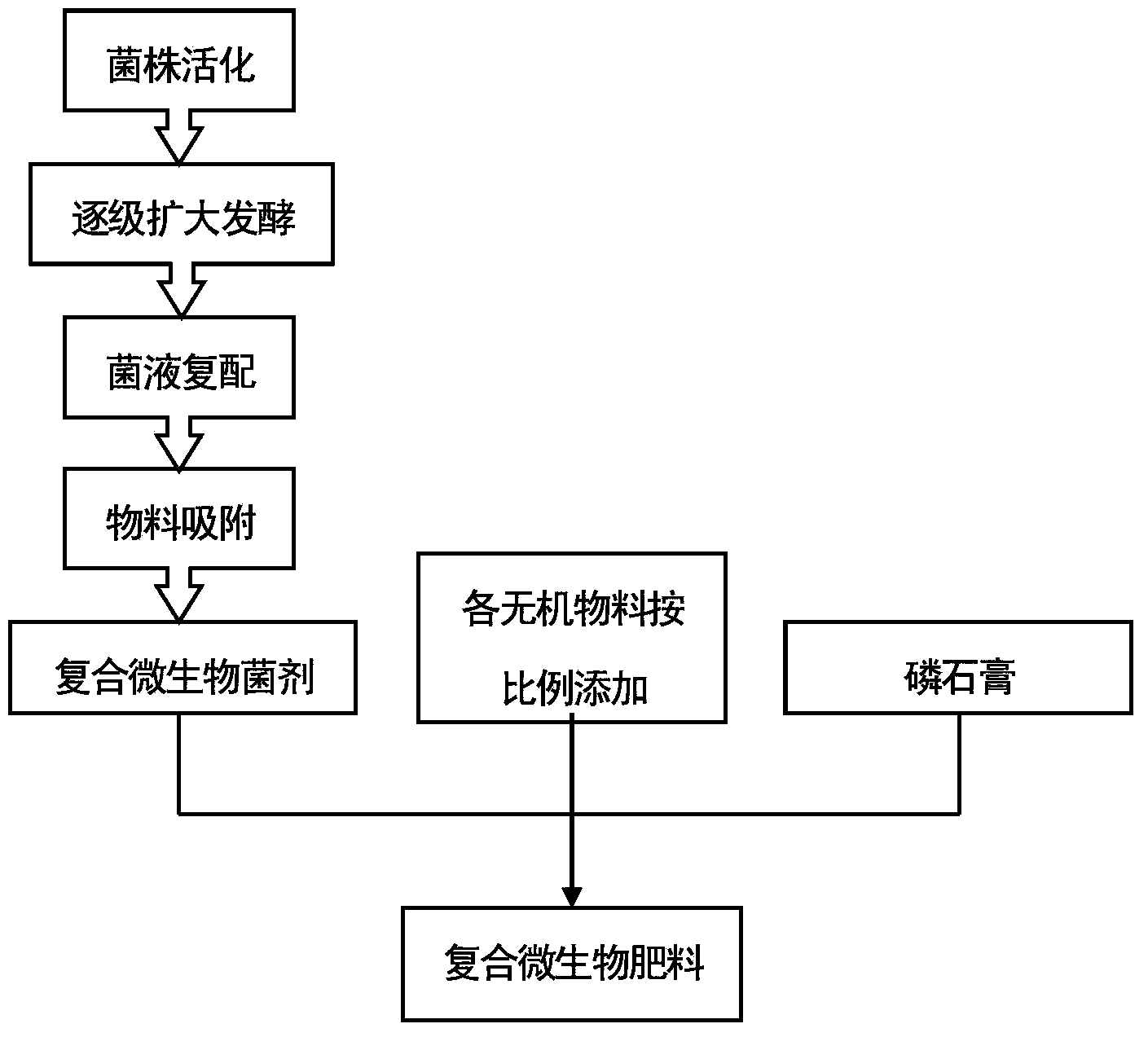

Method used

Image

Examples

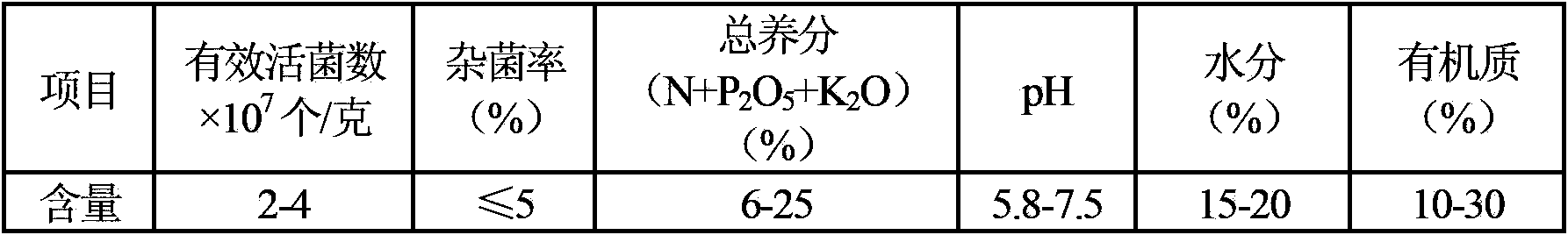

Embodiment 1

[0033] The sulfur-containing composite microbial fertilizer of the present invention comprises components in mass percent: 30% of phosphogypsum, 9% of composite microbial bacterial agent, 30% of moisture, and total nutrient (N+P 2 o 5 +K 2 The mass percentage of O) content is ≥ 6%, and the hydrolyzed slag is 40%; the composite microbial agent is obtained by mixing Bacillus megaterium and Thiobacillus Thiooxidans after fermentation and adsorption.

[0034] 1. Crushed phosphogypsum;

[0035] 2. Preparation of compound microbial bacterial agent: Bacillus megaterium and Thiobacillus Thiooxidans are produced by separate fermentation using fermentation equipment, and the fermented bacterial liquid is adsorbed with peat with a fineness of 60 mesh, and the fermentation liquid is mixed with peat The adsorption ratio is 1:4. Mix and pulverize the two adsorbed single bacterial agents according to the ratio of 2:1, and the effective number of viable bacteria in the bacterial agent will...

Embodiment 2

[0051] Except following technology, other is with example 1.

[0052] The sulfur-containing composite microbial fertilizer of the present invention includes components in mass percent: 15% of phosphogypsum, 4.1% of composite microbial bacterial agent, 9.1% of moisture, and total nutrients (N+P 2 o 5 +K 2 O) The mass percentage of the content is 26.4%, and the rapeseed cake is 28.9%. During the preparation process of the composite microbial bacterial agent, the fermented bacterial liquid of Bacillus megaterium and Thiobacillus thiooxidans is adsorbed with peat with a fineness of 70 mesh according to the ratio of fermentation liquid to peat = 1:3; single bacterial agent is mixed according to the ratio of 1:5 , crushed, the effective number of viable bacteria of the compound microbial agent reached 7.2×10 8 pcs / g.

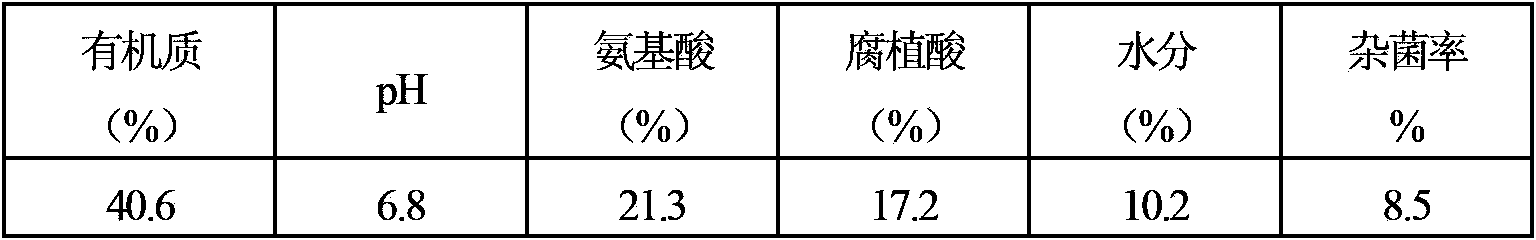

[0053] The added organic raw material is rapeseed cake. The basic properties of the treated organic raw materials are shown in Table 5.

[0054] Each material i...

Embodiment 3

[0063] Except following technology, other is with example 1.

[0064] The sulfur-containing composite microbial fertilizer of the present invention comprises components in mass percent: 25% of phosphogypsum, 7.5% of composite microbial bacterial agent, 11.4% of moisture, and total nutrient (N+P 2 o 5 +K 2 O) The mass percentage is 16.4%, and the hydrolyzed slag is 36.7%.

[0065] During the preparation of the composite microbial agent, the adsorbed bacterial agent fermented by Bacillus megaterium and Thiobacillus thiooxidans was mixed and pulverized at a ratio of 1:12, and the effective number of viable bacteria of the composite microbial agent reached 5.9×10 8 pcs / g.

[0066] The hydrolyzed slag was crushed and mixed with potassium hydroxide with a mass fraction of 8%, and crushed to 80 mesh. The basic properties of the treated organic raw materials are shown in Table 8.

[0067] Each material is added according to the formula described in Table 9.

[0068] The basic pr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fineness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com