Preparation method and application of porous material with surface grafted beta-cyclodextrin

A porous material, cyclodextrin technology, applied in chemical instruments and methods, other chemical processes, adsorption water/sewage treatment, etc., can solve problems such as particle surface reduction, increase specific surface area, and good environmental compatibility , good adsorption effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

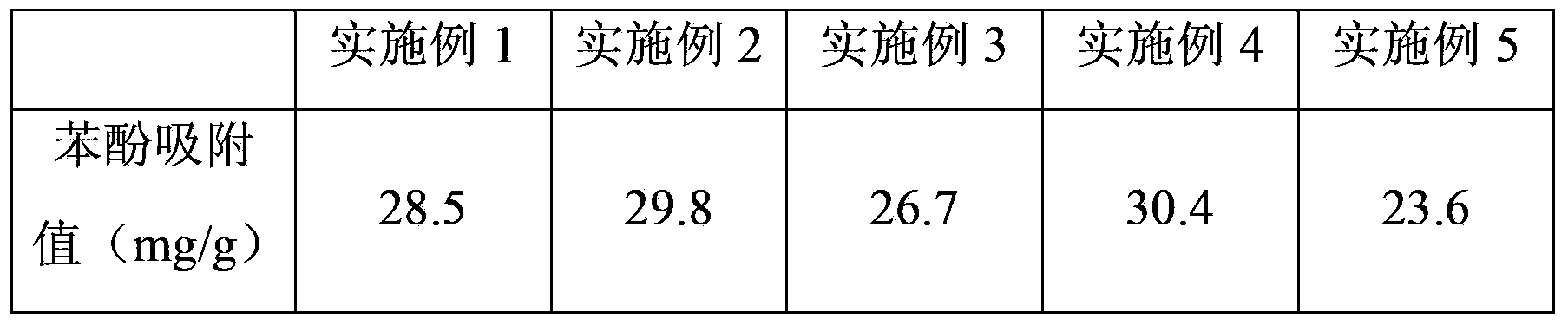

Embodiment 1

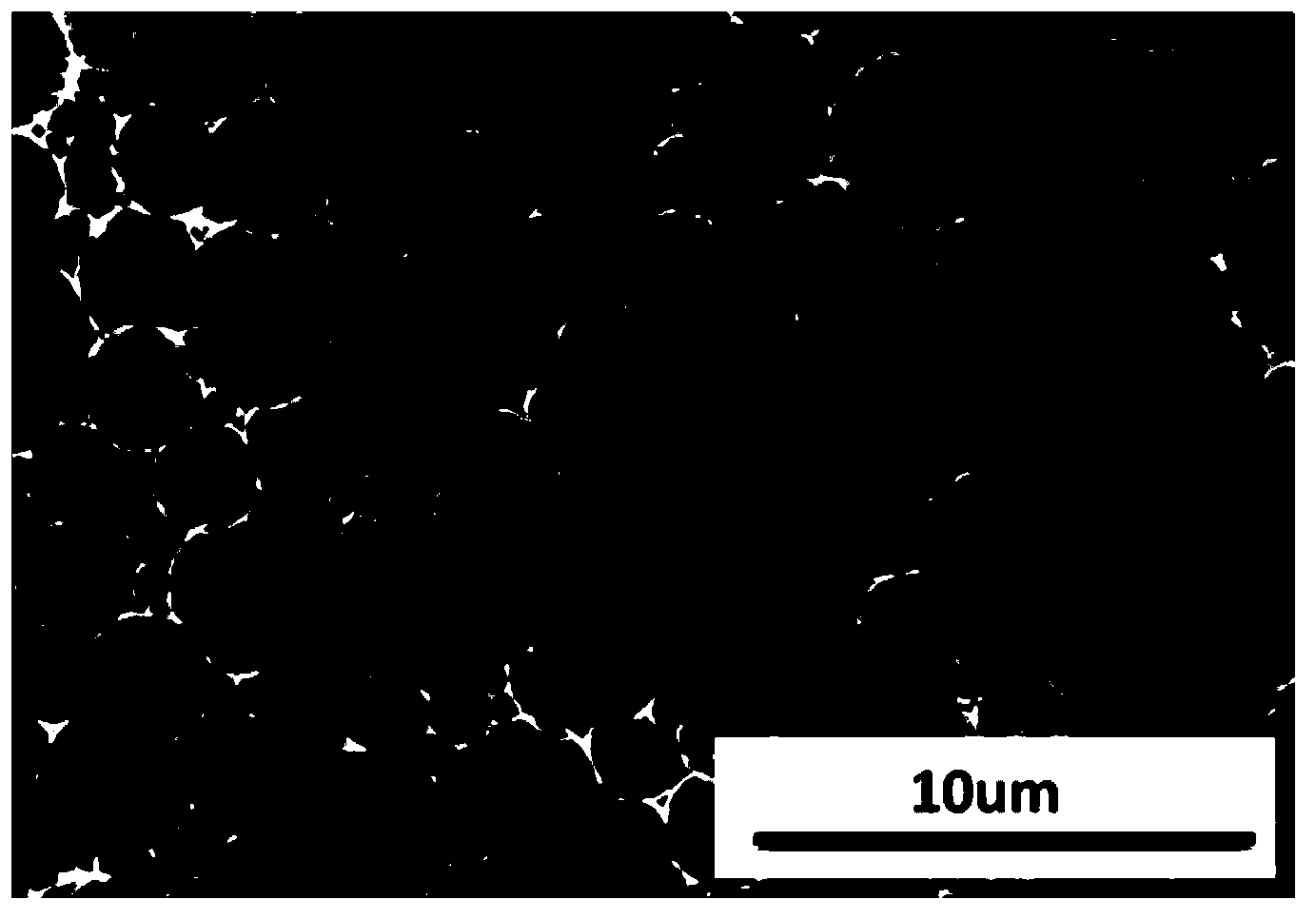

[0018] (1) Preparation of polystyrene porous material by concentrated emulsion polymerization: firstly, in a flask, 6 g of continuous phase styrene, 1.5 g of crosslinking agent p-vinylbenzene, and 802.02 g of emulsifier Span were mixed uniformly under high-speed stirring. Then configure the dispersed phase, dissolve 0.15g of water-soluble initiator potassium persulfate and 0.375g of electrolyte potassium sulfate in 90g of deionized water, mix well, and slowly add it dropwise to the continuous phase with a syringe under stirring state to disperse in the emulsion system The latex particles are uniform in size, forming a thick emulsion. Finally, it was reacted in a water bath at 70°C for 36 hours, and the product was taken out. Washing several times with ethanol and water, drying in a vacuum oven to constant weight, the polystyrene porous material can be obtained.

[0019] (2) Amination treatment of polystyrene porous material: swell 3 g of polystyrene porous material prepared i...

Embodiment 2

[0023] (1) Preparation of polystyrene porous material by concentrated emulsion polymerization: firstly, in a flask, 6 g of continuous phase styrene, 1.5 g of crosslinking agent p-vinylbenzene, and 802.02 g of emulsifier Span were mixed uniformly under high-speed stirring. Then configure the dispersed phase, dissolve 0.15g of water-soluble initiator potassium persulfate and 0.375g of electrolyte potassium sulfate in 90g of deionized water, mix well, and slowly add it dropwise to the continuous phase with a syringe under stirring state to disperse in the emulsion system The latex particles are uniform in size, forming a thick emulsion. Finally, it was reacted in a water bath at 70°C for 36 hours, and the product was taken out. Washing several times with ethanol and water, drying in a vacuum oven to constant weight, the polystyrene porous material can be obtained.

[0024] (2) Amination treatment of polystyrene porous material: swell 3 g of polystyrene porous material prepared i...

Embodiment 3

[0028](1) Preparation of polystyrene porous material by concentrated emulsion polymerization: first, in a flask, mix 6.85 g of continuous phase styrene, 1.72 g of crosslinking agent p-vinylbenzene and 800.89 g of emulsifier Span under high-speed stirring. . Then configure the dispersed phase, dissolve 0.17g of water-soluble initiator potassium persulfate and 0.42g of electrolyte potassium sulfate in 40g of deionized water, mix well, and slowly add it dropwise to the continuous phase with a syringe under stirring state to disperse in the emulsion system The latex particles are uniform in size, forming a thick emulsion. Finally, it was reacted in a water bath at 50°C for 24 hours, and the product was taken out. Washing several times with ethanol and water, drying in a vacuum oven to constant weight, the polystyrene porous material can be obtained.

[0029] (2) Amination treatment of polystyrene porous material: swell 3 g of polystyrene porous material prepared in step (1) in c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com