Saccharomyces cerevisiae capable of auto-synthesizing terpenoid substances and applications thereof

A technology of Saccharomyces cerevisiae and terpenoids, applied in the direction of microorganism-based methods, fermentation, microorganisms, etc., which can solve the problems of less terpenoids, high cost of terpenoids, and inability to guarantee the safety and edible properties of terpenoids, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

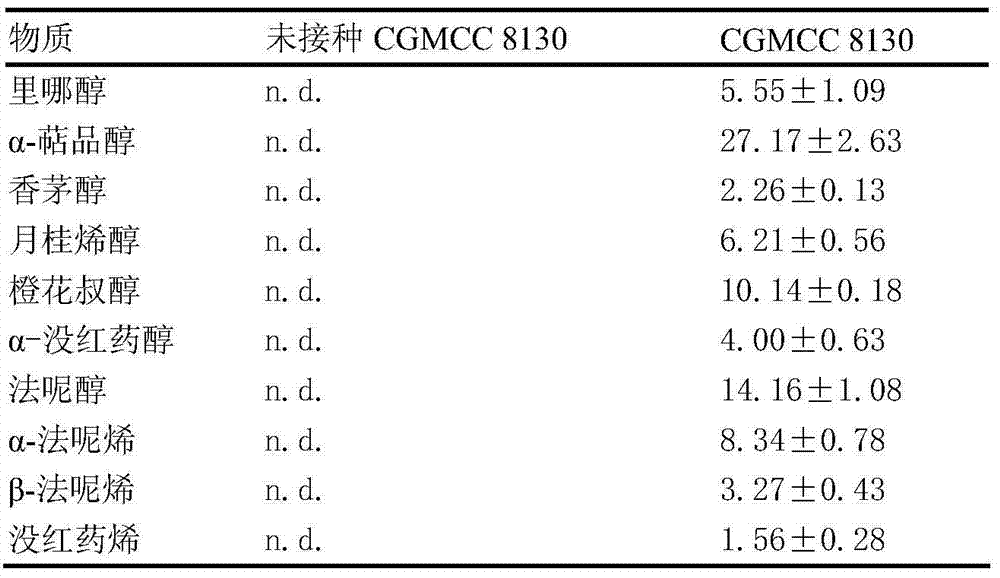

[0020] Example 1 Research on yeast liquid fermentation to produce terpenes

[0021] The Saccharomyces cerevisiae CGMCC No.8130 was inoculated into YNB fermentation medium, 150rpm, 30°C liquid fermentation for 48h, and the content of terpenes was determined by HS-SPME-GC-MS. The specific method is as follows:

[0022] 1. Sample preparation: add 1% CaCl to the fermentation broth 2 , after dissolving, centrifuge at 8000 rpm for 10 min at 4 °C, take the supernatant and filter it with a 0.22 μm filter.

[0023] 2. Gas chromatography-mass spectrometry detection: add 8 mL of clear solution, 3 g of sodium chloride, and 10 μL of 4-methyl-2-pentanol as an internal standard into a 15 mL headspace vial for headspace solid-phase microextraction. The conditions of headspace solid-phase microextraction are: three-phase (Car / DVB / PDMS) extraction head, preheating at 60°C for 5-10 minutes, extraction and adsorption for 30-50 minutes, and GC desorption for 5-10 minutes.

[0024] 3. Qualitative...

Embodiment 2

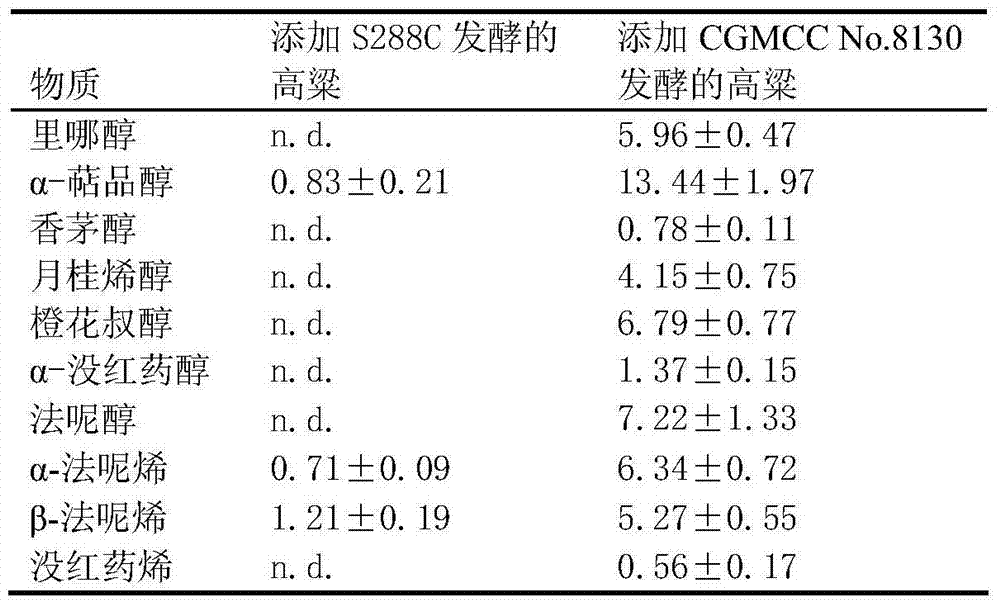

[0028] Example 2 Differences between Saccharomyces cerevisiae CGMCC No.8130 and commercial Saccharomyces cerevisiae S288C produced by solid-state fermentation and comparison with terpenoids produced during liquor production

[0029] The laboratory simulates the brewing process, adding the strain of Saccharomyces cerevisiae and commercial Saccharomyces cerevisiae respectively, and using sorghum as the raw material for solid-state fermentation. The specific scheme is as follows:

[0030] 1. Treatment of raw materials: put 200g in a large beaker, add 300mL of distilled water, treat in a water bath at 100°C for 2h, add water in the middle to maintain a certain amount of water, then add 5mL (100U / mL) of saccharification enzyme and treat at 60°C for 4h, and then divide into packages. (50g / bag) Sterilize at 110℃ for 30min in a high temperature resistant plastic bag.

[0031] 2. Inoculation and fermentation: The activated strains are inserted into the sterilized sorghum in the same am...

Embodiment 3

[0036] Example 3 Saccharomyces cerevisiae CGMCC No.8130 was added to increase the content of terpenoids in liquor and improve the flavor of liquor.

[0037] After activation of Saccharomyces cerevisiae (CGMCC No.8130 and commercial use), the inoculum of 1% (final concentration of 10 7 cfu / kg) into the fermented grains that have been mixed with Daqu, and then continue to ferment according to the traditional process.

[0038] After diluting the wine samples to 10°, the content of terpenoids was determined by HS-SPME-GC-MS. The analysis results are shown in Table 3. Compared with the normal control group, the types and contents of terpenoids in the liquor in the Saccharomyces cerevisiae CGMCC No.8130 group were significantly increased, while the types and contents of terpenoids in the liquor in the commercial Saccharomyces cerevisiae group were significantly higher than those in the control group. Not much difference than.

[0039] Table 3: Composition and content of terpenoids (...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com