Polyhedral oligomeric silsesquioxane (POSS)-based solid ionic liquid, and preparation method and application thereof

A kind of ionic liquid and solid-state technology, applied in the direction of silicon organic compound, hybrid capacitor electrolyte, etc., can solve the problems of poor contact of TiO2, unsatisfactory application, low conductivity, etc., and achieve good thermal stability and reliability Modification, good development and application prospects, sufficient supply effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

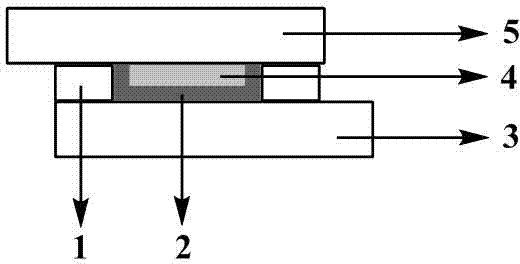

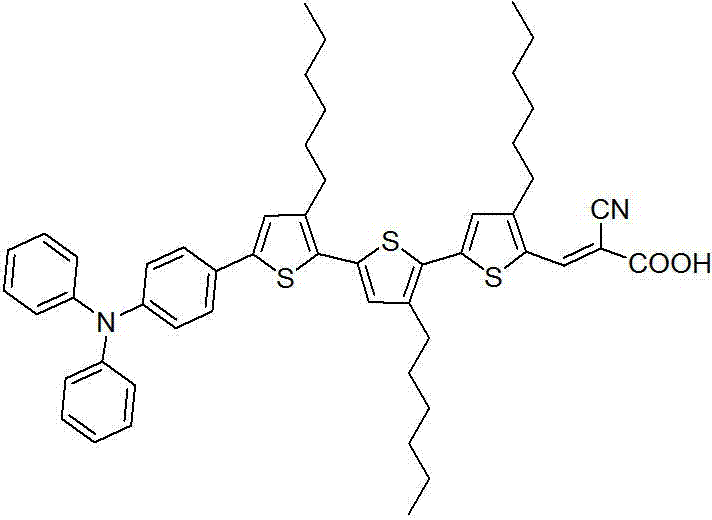

Method used

Image

Examples

Embodiment 1

[0033] Embodiment 1: intermediate 4 preparation of

[0034] 11.91g (0.06mol) 3 (References for synthetic methods R. Wakabayashi, Y. Sugiura, T. Shibue and K. Kuroda. Angew. Chem. Int. Ed. , 2011, 50 , 10708–10711) was added to 250ml of methanol, concentrated hydrochloric acid was added to adjust the solution to PH=3, hydrolyzed at 60°C for 3 days, and 1.56g of intermediate 4 was obtained by filtration, with a yield of 20%.

Embodiment 2

[0035] Embodiment 2: ionic liquid 6 preparation of

[0036] 1.82g (13 mmol) 3-acetoxymethylimidazole (intermediate 2) and 2.21g (1.25 mmol) of intermediate 5 were dissolved in 20ml of tetrahydrofuran and stirred at room temperature for 48 hours. After the reaction was completed, the clear solution in the upper layer was directly poured out, and the viscous solid at the bottom was drained with an oil pump. The solid was washed with tetrahydrofuran, ultrasonicated, and the clear solution in the upper layer was poured off, and the viscous solid at the bottom was drained again with an oil pump. Repeat the above steps more than 3 times to get 2.89g ionic liquid 6 , 80% yield.

Embodiment 3

[0037] Embodiment 3: ionic liquid 7 preparation of

[0038]

[0039] 2.13g (13mmol) of 3-ethylpropionylimidazole and 2.21g (1.25mmol) of intermediate 5 were dissolved in 20ml of tetrahydrofuran, and stirred at room temperature for 48 hours. After the reaction was completed, the clear solution in the upper layer was directly poured out, and the viscous solid at the bottom was drained with an oil pump. The solid was washed with tetrahydrofuran, ultrasonicated, and the clear solution in the upper layer was poured off, and the viscous solid at the bottom was drained again with an oil pump. Repeat the above steps more than 3 times to get 2.92g ionic liquid 7 , yield 76%.

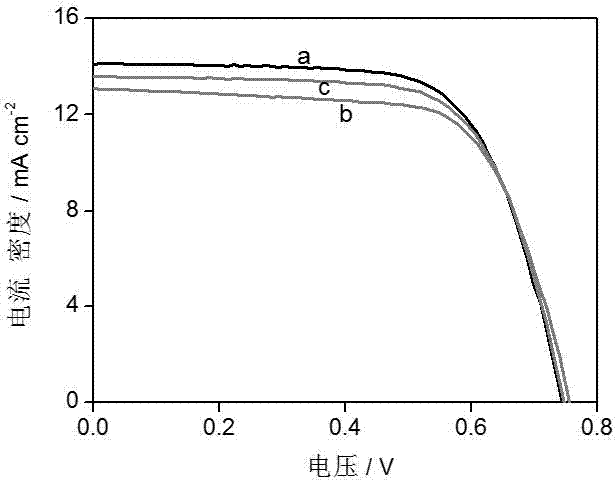

PUM

| Property | Measurement | Unit |

|---|---|---|

| energy conversion efficiency | aaaaa | aaaaa |

| energy conversion efficiency | aaaaa | aaaaa |

| energy conversion efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com