Preparation method for electrostatic spinning nano-fiber adopting porous structure

A technology of electrospinning and porous structure, which is applied in fiber processing, rayon manufacturing, fiber chemical characteristics, etc., can solve the problems of waste of polymer materials, and achieve the effect of improving load and adsorption capacity and large specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0030] 1. Weigh 2 g of polyacrylonitrile into a 50 ml clean Erlenmeyer flask, add 20 ml of N,N-dimethylformamide, mix well and fully dissolve it as mother liquor. Then weigh different masses of Fe with a diameter of about 50nm 2 O 3 Nano particles, Fe 2 O 3 The mass ratio of the nanoparticles to polyacrylonitrile is 1-20:100, and the particles are uniformly dissolved by ultrasonic and sealed for later use.

[0031] figure 1 Fe used for 2 O 3 Nano particles, the diameter is about 50nm.

[0032] 2. Electrospinning conditions: needle inner diameter, 0.2~1 mm; distance between needle and receiving plate, 10~20 cm; voltage, 15~20 kV; solution flow, 0.5~2 ml / h; electrospinning time, 10~ 30 min.

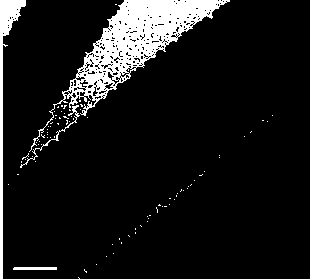

[0033] image 3 , 4 Doped Fe in this example 2 O 3 The transmission electron microscope and scanning electron microscope photos of the fibers after the nanoparticles, from image 3 , 4 Fe can be clearly seen on the 2 O 3 Nano particles cover the surface of the fiber.

[0034] 3. The composite nan...

example 2

[0037] 1. Weigh 2 g of polylactic acid into a 50 ml clean Erlenmeyer flask, add 30 ml of chloroform, mix it evenly and fully dissolve it as mother liquor. Then weigh different masses of SiO with a diameter of about 40nm 2 Nano particles, SiO 2 The mass ratio of the nanoparticles to polyacrylonitrile is 1-20:100, and the particles are uniformly dissolved by ultrasonic and sealed for use.

[0038] Such as Figure 7 As shown, the SiO used 2 The diameter of the nanoparticles is around 40nm.

[0039] 2. Electrospinning conditions: needle inner diameter, 0.2~1 mm; distance between needle and receiving plate, 10~20 cm; voltage, 15~20 kV; solution flow, 0.5~2 ml / h; electrospinning time, 15~ 30 min.

[0040] Picture 8 Doped SiO for this example 2 Scanning electron micrograph of the fiber after the nanoparticles, from image 3 , 4 SiO can be clearly seen on the 2 Nano particles cover the surface of the fiber.

[0041] 3. The composite nanofibers are soaked in a diluted hydrofluoric acid aqueo...

example 3

[0044] 1. Weigh 2 g of polyacrylonitrile into a 50 ml clean Erlenmeyer flask, add 20 ml of N,N-dimethylformamide, mix well and fully dissolve it as mother liquor. Then weigh different masses of SiO with a diameter of about 40nm 2 Nano particles, SiO 2 The mass ratio of the nanoparticles to polyacrylonitrile is 1-20:100, and the particles are uniformly dissolved by ultrasonic and sealed for use.

[0045] 2. Electrospinning conditions: inner diameter of needle, 0.2~1 mm; distance between needle and receiving plate, 10~20 cm; voltage, 15~20 kV; solution flow, 0.5~2 ml / h; electrospinning time, 15~ 30 min.

[0046] 3. The composite nanofiber is soaked in concentrated NaOH solution (concentration 20%-60%) for 12-24 hours to remove the SiO doped into the nanofiber 2 Nanoparticles to obtain porous nanofibers.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com