Method for preparing polypeptide copolymer porous nanofiber by using electrostatic spinning

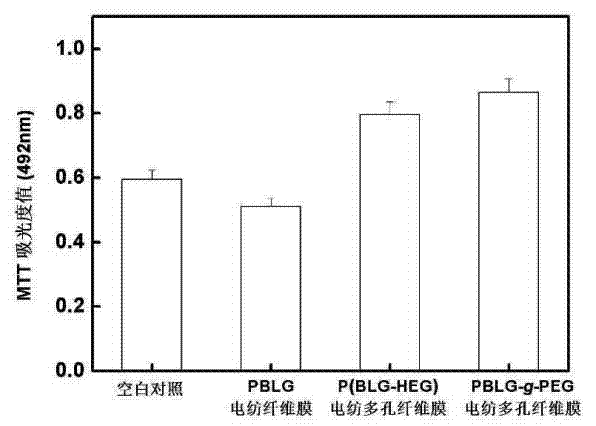

A technology of electrospinning and nanofibers, which is applied in the direction of spinning solution preparation, single-component copolyamide artificial filament, fiber treatment, etc., can solve problems such as constraints and poor cell adhesion performance, and achieve good biophase Capacitance, effect of promoting cell adhesion and growth

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

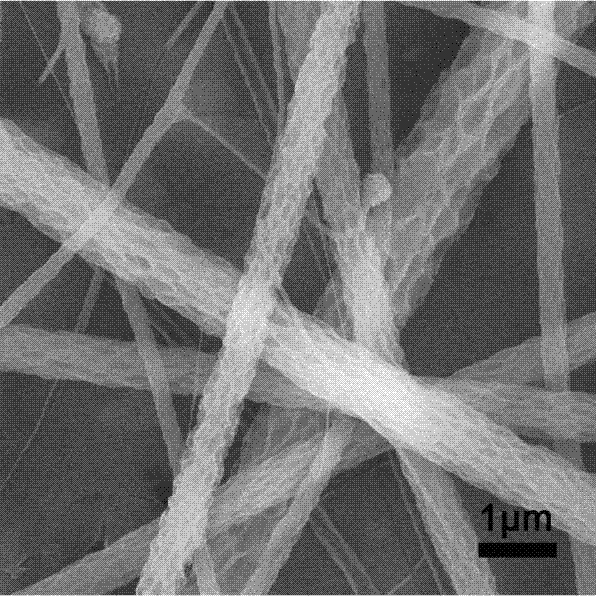

[0031] A method for preparing polypeptide copolymer porous nanofibers by electrospinning, the preparation steps are:

[0032] (1) Hydrophilic modification of homopolypeptide

[0033] For hydrophobic peptides—poly( -Benzyl L-glutamate) (PBLG) for hydrophilic modification:

[0034] In a 250mL reaction bottle, add 2g of poly( -benzyl L-glutamate) (PBLG), 100mL refined dioxane and 3mL ethanolamine (ETA), reacted with electromagnetic stirring at 60°C for 11 hours, then precipitated, filtered, and dried in vacuo to obtain white poly( -Benzyl L-glutamate-hydroxyethylglutamine) [P(BLG-HEG)] solid 1.8 g; degree of substitution with ethanolamine (ETA) 5%.

[0035] (2) Preparation of spinning dope

[0036] 0.16g of poly( -Benzyl L-glutamate-hydroxyethylglutamine)[P(BLG-HEG)] random copolymer was dissolved in 2 mL of volatile organic solvent tetrahydrofuran / dichloromethane with volume ratio of 80:20 (v:v) In a compound solvent of methane (THF / DCM), a solution with a concentratio...

Embodiment 2

[0045] A method for preparing polypeptide copolymer porous nanofibers by electrospinning, the preparation steps are:

[0046] (1) Hydrophilic modification of homopolypeptide

[0047] Basic content is the same as embodiment 1, and difference is:

[0048] Poly( The molecular weight of -benzyl L-glutamate) (PBLG) is 230000g / mol, ethanolamine (ETA) is 6mL, the reaction time of electromagnetic stirring under 60 ℃ is 20 hours, and the substitution degree of ethanolamine (ETA) is 11%.

[0049] (2) Preparation of spinning dope

[0050] 0.14g of poly( -Benzyl L-glutamate-hydroxyethylglutamine) [P(BLG-HEG)] random copolymer is dissolved in the volatile organic solvent trichloromethane / tri In the compound solvent of fluoroacetic acid (TCM / TFA), stir evenly, and prepare the electrospinning stock solution with a concentration of 5% (w / v).

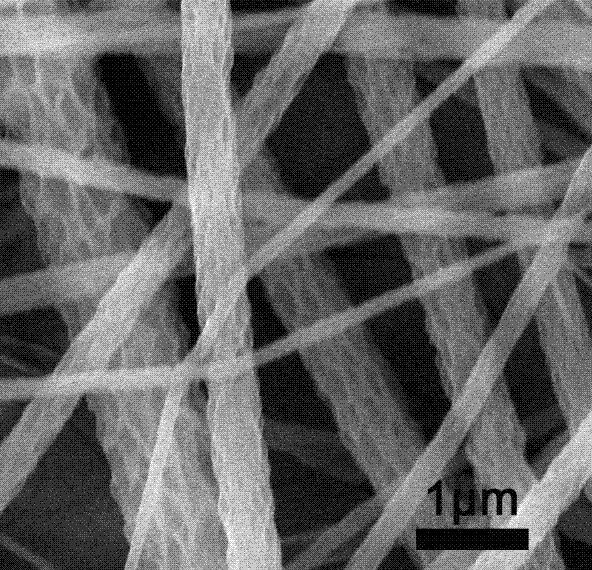

[0051] (3) Perform high-voltage electrospinning

[0052] The electrospinning stock solution in step (2) was subjected to high-voltage electrosp...

Embodiment 3

[0058] A method for preparing polypeptide copolymer porous nanofibers by electrospinning, the preparation steps are:

[0059] (1) Hydrophilic modification of the homopolypeptide (same as Example 2).

[0060] (2) Preparation of spinning dope

[0061] 0.26g of poly( -Benzyl L-glutamate-hydroxyethylglutamine) [P(BLG-HEG)] random copolymer is dissolved in the volatile organic solvent trichloromethane / tri In a compound solvent of fluoroacetic acid (TCM / TFA), stir evenly to prepare an electrospinning stock solution with a concentration of 13% (w / v).

[0062] (3) Perform high-voltage electrospinning

[0063] The electrospinning stock solution in step (2) was subjected to high-voltage electrospinning under the conditions of a spinning voltage of 13kV, a receiving distance from the spinneret to the aluminum foil of 13cm, and an extrusion flow rate of 1mL / h.

[0064] (4) vacuum drying

[0065] (Same as Example 1), the target product—porous nanofibers with high specific surface are...

PUM

| Property | Measurement | Unit |

|---|---|---|

| degree of substitution | aaaaa | aaaaa |

| degree of substitution | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com