Application of lactobacillus plantarum in reducing blood fat and assisting fat-reducing

A technology of Lactobacillus plantarum and blood lipid lowering, which is applied in the field of microorganisms and can solve problems such as high prices

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

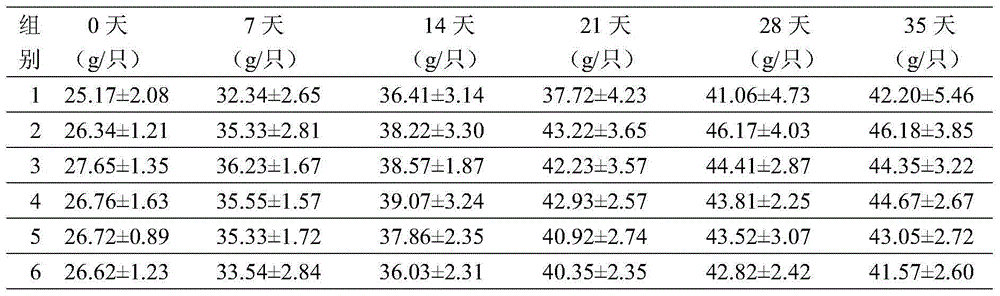

[0046] Lowering serum cholesterol in vivo test (animal test)

[0047] The invention adopts a high-fat feed feeding method, and uses Kunming mice to build an animal model of hyperlipidemia.

[0048] The formula of high-fat feed is: basic feed (as shown in Table 1) (weight percentage) 78.8%, egg yolk powder 10%, lard 10%, cholesterol 1%, deoxycholate 0.2%, at the same time Lactobacillus plantarum CGMCC No.8198 was prepared into a bacterial suspension and administered to mice by gavage, and five weeks later, the contents of total cholesterol (TC), triglyceride (TG) and low-density lipoprotein cholesterol (LDL-C) in the serum of the mice were detected.

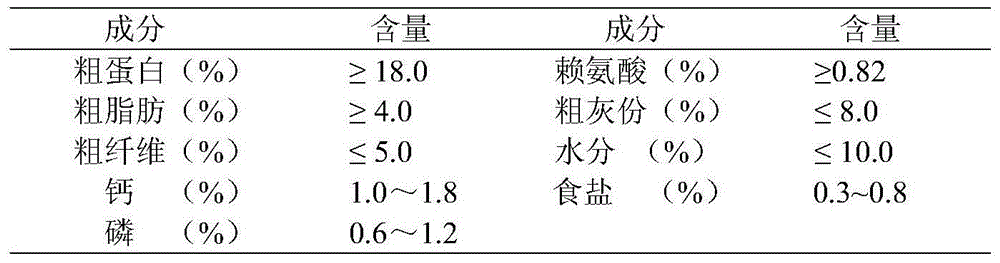

[0049] Table 1 Main nutrient components of basal feed (weight percentage)

[0050]

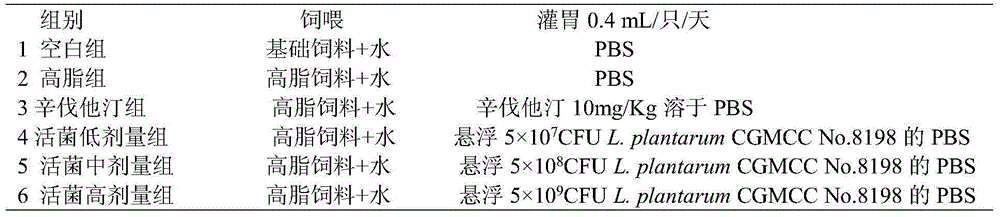

[0051] 1. Grouping of experimental animals

[0052] Sixty male Kunming mice (4 weeks old, 20 ± 2 g) were randomly divided into 6 groups after 5 days of adaptive feeding, with 10 mice in each group. The specific groups are shown in Table 2.

...

Embodiment 2

[0073] Preparation of dairy products with hypolipidemic function

[0074] Fermented yogurt process:

[0075] Raw milk pretreatment→ingredients→homogenization→sterilization→inoculation→fermentation→cooling→packaging→refrigeration

[0076] Key points of the process:

[0077] 1. Raw milk pretreatment: filter the raw milk (cow's milk) to remove larger pollutants in the milk, and use a centrifugal milk cleaner to remove some tiny impurities and bacteria.

[0078] 2. Ingredients: 2wt% (raw milk weight) of milk powder is added to adjust the non-fat dry matter, and 5wt% (raw raw milk weight) of sucrose is added to adjust the taste of yogurt.

[0079] 3. Homogenization: temperature 50-60℃, homogenization pressure 10-15MPa.

[0080] 4. Sterilization: adopt high temperature pasteurization method, 90-95°C, 5 minutes.

[0081] 5. Inoculation: When the milk temperature drops to about 42°C, add 3wt% of Lactobacillus plantarum CGMCC No.8198 that has been activated for the third generation...

Embodiment 3

[0088] Preparation of fermented fruit and vegetable juice

[0089] Process flow of fermented cucumber and cantaloupe compound fruit and vegetable juice:

[0090] Wash slices→flash steaming→juicing→filtering→blending→homogenization→sterilization→cooling→inoculation→fermentation→post-cooking→filling→refrigeration

[0091] Key points of the process:

[0092] 1. Washing and slicing: first wash, peel and slice the cucumber and cantaloupe.

[0093] 2. Flash evaporation: use the method of flash evaporation to inactivate the enzyme, in a pressure cooker, 121°C, 0.5-1min, and quickly exhaust.

[0094] 3. Juicing and filtering: Use a juicer to squeeze the cucumber and cantaloupe juice separately and filter.

[0095] 4. Deployment and homogenization: 15wt% of cucumber juice and 30wt% of cantaloupe juice are prepared, then sucrose is used to adjust the content of soluble solids to 10°Brix, and 0.2% of stabilizer CMC-Na is added to mix evenly, using two-stage homogenization method , fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com