Preparation method of carbon nanoparticle with high luminous intensity

A technology of carbon nanoparticles and luminous intensity, applied in the direction of luminescent materials, nanotechnology, chemical instruments and methods, etc., can solve the problems of low luminous intensity, difficult separation, low yield of carbon nanoparticles, etc., and achieve high luminous intensity, reaction Low temperature, easy to control effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] (1) Mix and grind 0.50 g of tartaric acid and 0.25 g of tyrosine solid in a mortar, and the mass ratio of tartaric acid and tyrosine is 2:1;

[0031] (2) Add the mixed and ground tartaric acid and tyrosine solids into 30 ml of ethylene glycol solvent and stir evenly to obtain an ethylene glycol mixture of tartaric acid and tyrosine. The mass concentration of tartaric acid and tyrosine in the mixture is 2.2%;

[0032] (3) Transfer the ethylene glycol mixture of tartaric acid and tyrosine into a reaction kettle, conduct a solvothermal reaction at 180° C. for 6 hours, and cool the reaction kettle to room temperature naturally to obtain a carbon nanoparticle solution.

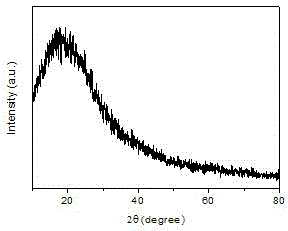

[0033] figure 1 The X-ray diffraction pattern of the carbon nanoparticles prepared for this example has a very broad peak at about 2θ=20°, which is a characteristic peak of the amorphous form of carbon.

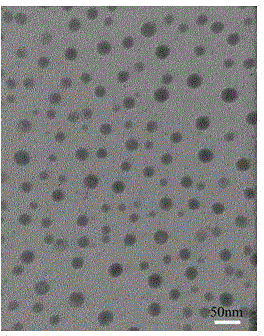

[0034] figure 2 The transmission electron micrograph of the carbon nanoparticle prepared in this emb...

Embodiment 2

[0040] (1) Mix and grind tartaric acid and tyrosine solids in a mortar evenly, the mass ratios of tartaric acid and tyrosine are 5:1, 2:1, 1:1, 1:2 respectively, and the solid mixture is 1.20 grams ;

[0041] (2) Add the mixed and ground tartaric acid and tyrosine solids into 30 ml of ethylene glycol solvent and stir evenly to obtain an ethylene glycol mixture of tartaric acid and tyrosine. The mass of tartaric acid and tyrosine in the mixture is The concentration is 3.5%;

[0042] (3) Transfer the ethylene glycol mixtures of tartaric acid and tyrosine into a reaction kettle, conduct a solvothermal reaction at 180° C. for 6 hours, and cool the reaction kettle to room temperature naturally to obtain a carbon nanoparticle solution.

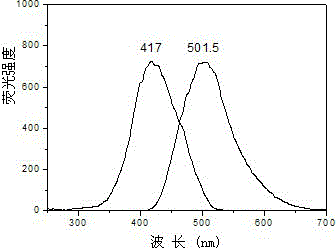

[0043] The fluorescence properties of carbon nanoparticles prepared with different raw material ratios are similar, the best excitation wavelength of each sample is around 420nm, and the best emission wavelength is around 500nm. When the mass rati...

Embodiment 3

[0046] (1) Mix and grind 2.0 grams of tartaric acid and 1.0 grams of phenylalanine in a mortar, and the mass ratio of tartaric acid and phenylalanine is 2:1;

[0047] (2) Add the mixed and ground tartaric acid and phenylalanine solids into 25 ml of ethylene glycol solvent and stir evenly to obtain an ethylene glycol mixture of tartaric acid and phenylalanine, in which tartaric acid and phenylalanine The mass concentration is 9.7%;

[0048] (3) Transfer the ethylene glycol mixture of tartaric acid and phenylalanine into a reaction kettle, conduct a solvothermal reaction at 150° C. for 6 hours, and cool the reaction kettle to room temperature naturally to obtain a carbon nanoparticle solution.

[0049]The fluorescence properties of carbon nanoparticles prepared by reacting different amino acids with the same organic acid are similar, but the fluorescence excitation wavelength is different from the corresponding emission wavelength, Figure 9 is the fluorescence spectrum of carb...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com