Visible light catalyst for high-efficiently degrading organic dye waste water and preparation method thereof

A technology of organic dyes and catalysts, which is applied in the field of environment and energy, can solve the problems of affecting photocatalytic efficiency, difficulty in recycling, and high recombination probability of photogenerated carriers, so as to improve photocatalytic degradation efficiency, low-cost recycling, waste water The effect of simple processing technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

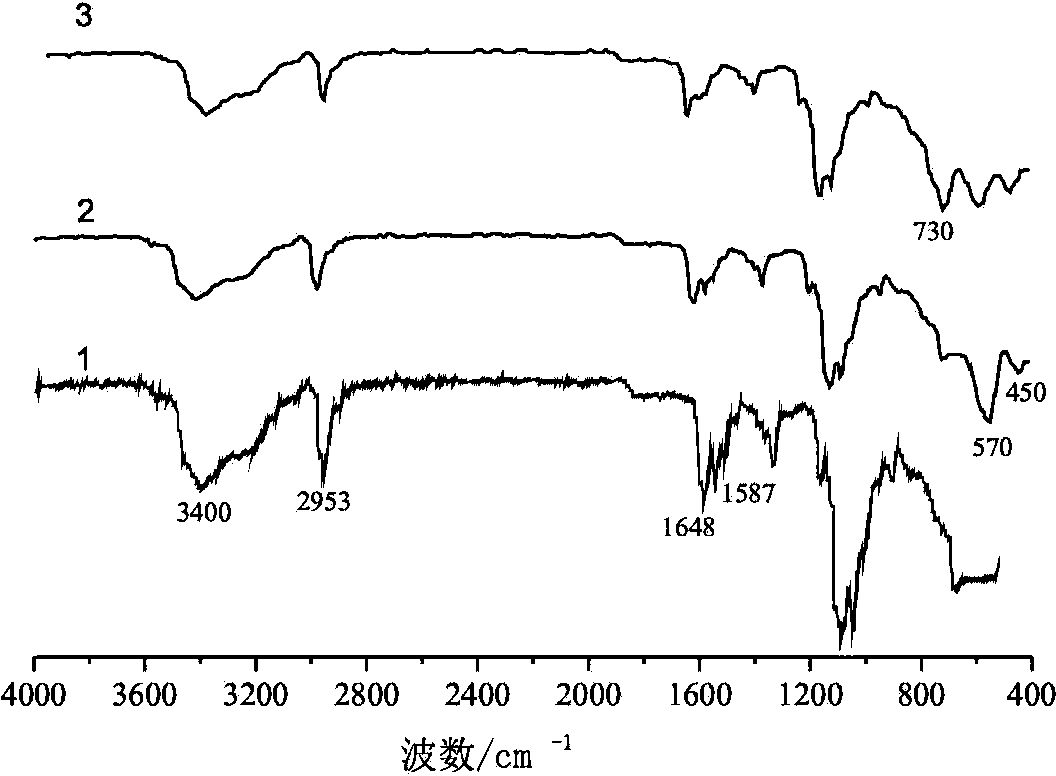

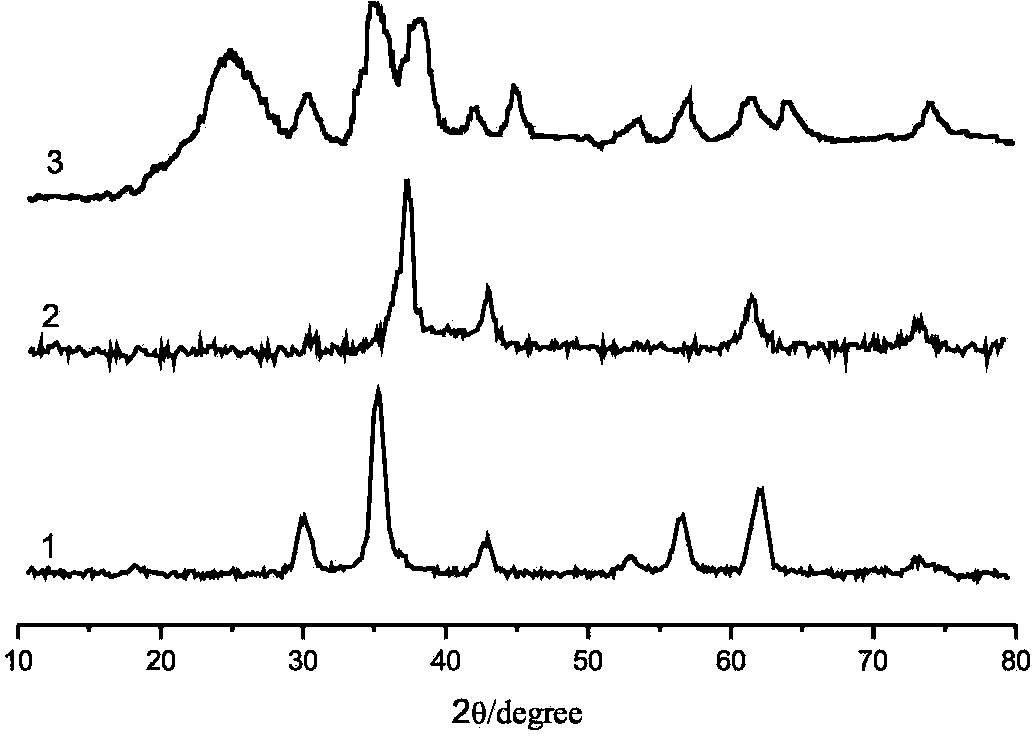

Embodiment 1

[0024] This example is the preparation of cuprous oxide / cross-linked chitosan / zinc ferrite ternary composite visible light catalyst. The specific process is: add 10g chitosan to 250g 0.50mol / L acetic acid aqueous solution, stir and dissolve to obtain chitosan acetic acid solution; add 5g nanometer zinc ferrite to the chitosan acetic acid solution, stir and disperse for 0.5h; Slowly add 10wt% dilute ammonia water to the above solution to adjust the pH value of the solution to 7, then dropwise add 40g of 25wt% glutaraldehyde aqueous solution to carry out cross-linking reaction, react at 50°C for 3h, apply a magnetic field to separate, and obtain a spherical The product was thoroughly washed with absolute ethanol and deionized water in turn, and dried in vacuum at 50°C to obtain a cross-linked chitosan / zinc ferrite complex; add 0.025mol of copper sulfate hydrate into 500mL of deionized water, stir until completely dissolved, and add 0.0625mmol polyethylene glycol PEG-8000, 31.2g ...

Embodiment 2

[0026] This example is the preparation of cuprous oxide / cross-linked chitosan / zinc ferrite ternary composite visible light catalyst. The specific process is: add 10g chitosan to 300g 0.50mol / L acetic acid aqueous solution, stir and dissolve to obtain chitosan acetic acid solution; add 2.5g nanometer zinc ferrite to the chitosan acetic acid solution, stir and disperse for 1 hour; Slowly add 10wt% dilute ammonia water to the above solution to adjust the pH value of the solution to 8, then dropwise add 70g of 25wt% glutaraldehyde aqueous solution to carry out cross-linking reaction, react at 60°C for 5h, apply a magnetic field to separate, and obtain a spherical The product was thoroughly washed with absolute ethanol and deionized water in turn, and dried under vacuum at 50°C to obtain a cross-linked chitosan / zinc ferrite complex; add 0.05 mol of copper sulfate hydrate into 500 mL of deionized water, stir until completely dissolved, and add 0.1111mmol polyethylene glycol PEG-8000...

Embodiment 3

[0028] This example is the preparation of cuprous oxide / cross-linked chitosan / zinc ferrite ternary composite visible light catalyst. The specific process is: add 10g chitosan into 400g 0.50mol / L acetic acid aqueous solution, stir and dissolve to obtain chitosan acetic acid solution; add 1.7g nano-zinc ferrite to the chitosan acetic acid solution, stir and disperse for 1.5h Slowly add 10wt% dilute ammonia water to the above solution to adjust the pH value of the solution to 9, then dropwise add 120g of 25wt% glutaraldehyde aqueous solution to carry out cross-linking reaction, react at 70°C for 7h, apply a magnetic field to separate, and obtain The spherical product was thoroughly washed with absolute ethanol and deionized water in turn, and dried in vacuum at 50°C to obtain a cross-linked chitosan / zinc ferrite complex; add 0.15 mol of copper sulfate hydrate into 500 mL of deionized water, stir until completely dissolved, Add 0.3000mmol polyethylene glycol PEG-8000, 337.5g cross...

PUM

| Property | Measurement | Unit |

|---|---|---|

| energy | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com