Method for carrying out oleophylic and hydrophobic modification on surface of water-soluble inorganic oxidant or inorganic salt

An inorganic oxidant, lipophilic and hydrophobic technology, applied in the direction of inorganic chemistry, chemical instruments and methods, peroxide/peroxyhydrate/peroxyacid/superoxide/ozonide, etc., can solve the problem of water decomposition, easy Moisture agglomeration, easy hydrolysis and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

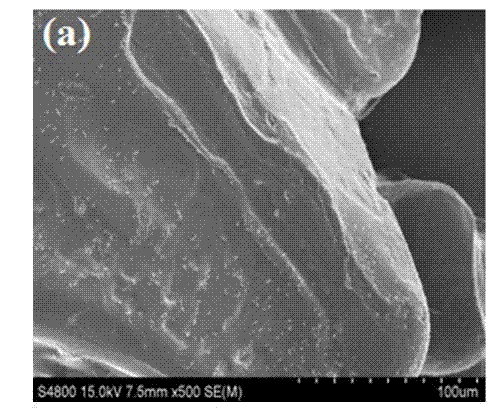

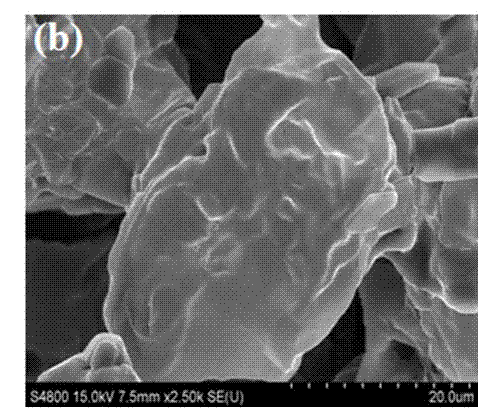

Image

Examples

Embodiment Construction

[0012] 1. Modification process:

[0013] 1. Stir a certain mass ratio of aluminum chloride and deionized water in a three-necked flask until completely dissolved, add a mixture of methanol and propylene glycol of the corresponding mass ratio, heat to reflux, separate methanol, and dry it in vacuum to make intermediate product A spare.

[0014] 2. Accurately weigh a certain amount of oleic acid, n-butanol and n-hexanoic acid and mix them in a three-necked reaction flask, add a certain amount of titanium sulfate, and after 1.5 hours of reaction, add a certain amount of intermediate product A and stir. Add quantitative sodium persulfate (or cerium oxide, sodium peroxide, ammonium persulfate, potassium persulfate) to continue the reaction for 2 hours. Cool, stand still, separate and dry to get the product.

[0015] The percentage (100%) of each component accounting for the total weight of the feed in its specific composition is:

[0016] Scheme 1: 3% aluminum chloride, 3% metha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com