Supercapacitor electrode material molybdenum sulfide-multiwalled carbon nanotube and preparation method thereof

A technology of multi-walled carbon nanotubes and supercapacitors, applied in hybrid capacitor electrodes, hybrid/electric double-layer capacitor manufacturing, nanotechnology for materials and surface science, etc., can solve low specific capacitance, poor conductivity, impact Application and other issues, to achieve the effect of improving specific surface area and conductivity, low cost, improving specific capacitance and electrochemical stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

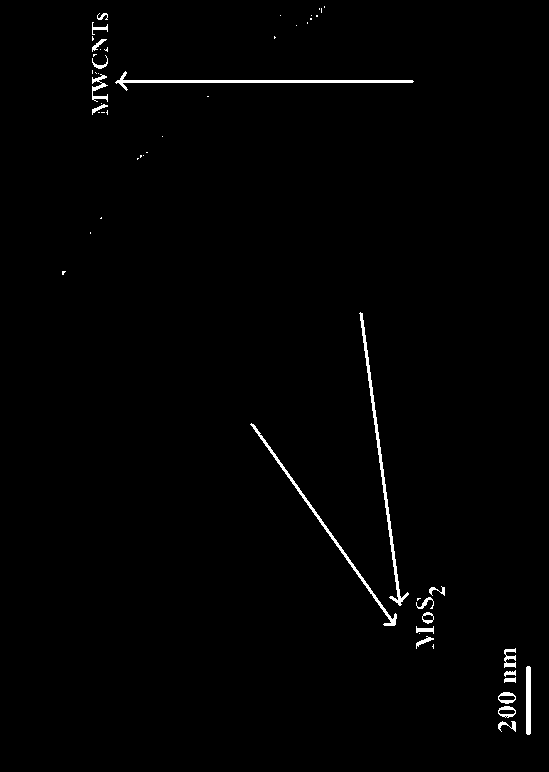

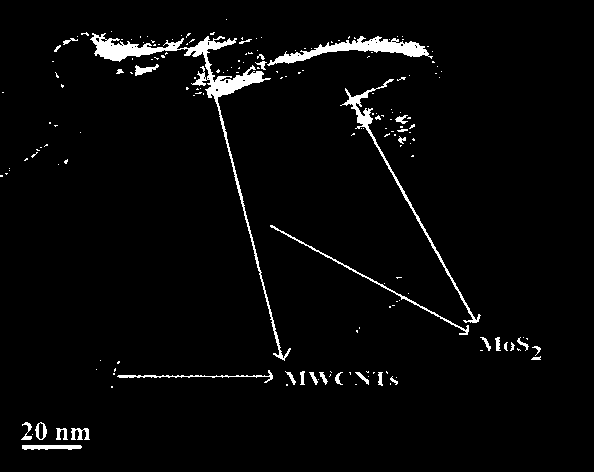

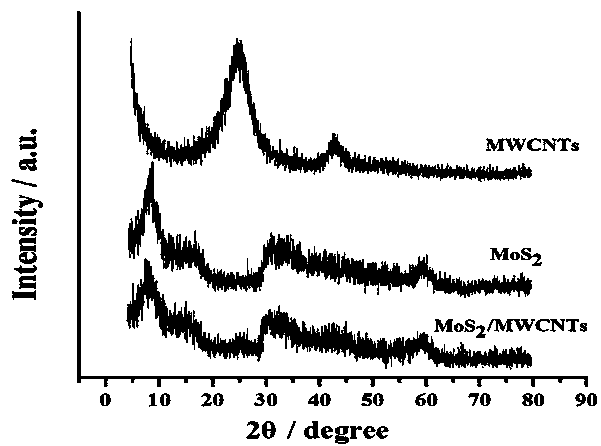

[0029] (1) Preparation of molybdenum sulfide-multi-walled carbon nanotube composites

[0030] Weigh 0.017 g MWCNTs and add it into 40 mL double-distilled water, and obtain a uniformly dispersed MWCNTs suspension after ultrasonication; weigh 0.3 g Na 2 MoO 4 2H 2 Add O to the above mixture, ultrasonically disperse for 30 min, adjust the pH of the solution to 6.5 with 0.1 mol / L NaOH, add 0.8 g of L-cysteine, dilute to 80 mL with twice distilled water, and stir vigorously for 1 h , Add the above mixture into a 100 mL polytetrafluoroethylene hydrothermal reactor, and the filling degree of the reactor is 80%. The hydrothermal reactor was put into a blast drying oven, reacted at 180 °C for 48 h, and then the reactor was naturally cooled to room temperature. The resulting product was centrifuged and washed three times with twice distilled water and ethanol, respectively. Then the obtained product was put into a vacuum drying oven and dried at 80 °C for 20 h to obtain the molybden...

Embodiment 2

[0038] (1) Preparation of molybdenum sulfide-multi-walled carbon nanotube composites

[0039] Weighed 0.017 g MWCNTs and added it into 40 mL double-distilled water, and obtained a uniformly dispersed MWCNTs suspension after ultrasonication. Weigh 0.4 g Na 2 MoO 4 2H 2Add O to the above mixture, ultrasonically disperse for 30 min, adjust the pH of the solution to 6.5 with 0.1 mol / L NaOH, add 1.1 g of L-cysteine, dilute to 80 mL with twice distilled water, and stir vigorously for 1 h . The above mixture was added into a 100 mL polytetrafluoroethylene hydrothermal reaction kettle, and the filling degree of the reaction kettle was 80%. The hydrothermal reactor was put into a blast drying oven, reacted at 180 °C for 49 h, and then the reactor was naturally cooled to room temperature. The resulting product was centrifuged and washed three times with twice distilled water and ethanol, respectively. Then the obtained product was put into a vacuum drying oven and dried at 80 °C f...

Embodiment 3

[0043] (1) Preparation of molybdenum sulfide-multi-walled carbon nanotube composites

[0044] Weighed 0.017 g MWCNTs and added it into 40 mL double-distilled water, and obtained a uniformly dispersed MWCNTs suspension after ultrasonication. Weigh 0.5 g Na 2 MoO 4 2H 2 Add O to the above mixture, ultrasonically disperse for 30 min, adjust the pH of the solution to 6.5 with 0.1 mol / L NaOH, add 1.3 g of L-cysteine, dilute to 80 mL with twice distilled water, and stir vigorously for 1 h . The above mixture was added into a 100 mL polytetrafluoroethylene hydrothermal reaction kettle, and the filling degree of the reaction kettle was 80%. The hydrothermal reactor was put into a blast drying oven, reacted at 180 °C for 50 h, and then the reactor was naturally cooled to room temperature. The resulting product was centrifuged and washed three times with twice distilled water and ethanol, respectively. Then the obtained product was put into a vacuum drying oven and dried at 80 °C ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com