A kind of compound micelle of amphotericin b polymer with high drug load and preparation method thereof

A technology of amphotericin and compound micelle, which is applied in the field of medicine and achieves the effects of not easy aggregation, good stability, improved range and convenience

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

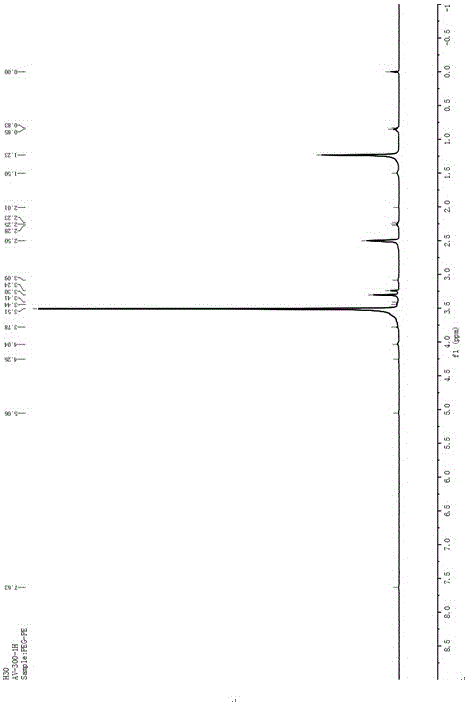

[0045] Example 1: Preparation of composite micelles of polyethylene glycol 2000-phosphatidylethanolamine and amphotericin B (molar ratio is 0.4:1)

[0046] Weigh 8.4 mg of amphotericin B and 10 mg of polyethylene glycol 2000-phosphatidylethanolamine and dissolve it in 20 ml of methanol, remove the organic solvent by rotary evaporation under reduced pressure in a water bath at 50 ° C, add 10 ml of distilled water, hydrate for 15 minutes, and pass through a micrometer of 0.22 μm Pore membrane filtration, that is, composite micelles. It was measured that the encapsulation efficiency was 95.8%, the drug loading was 44.4%, and the particle size was 57.89nm.

Embodiment 2

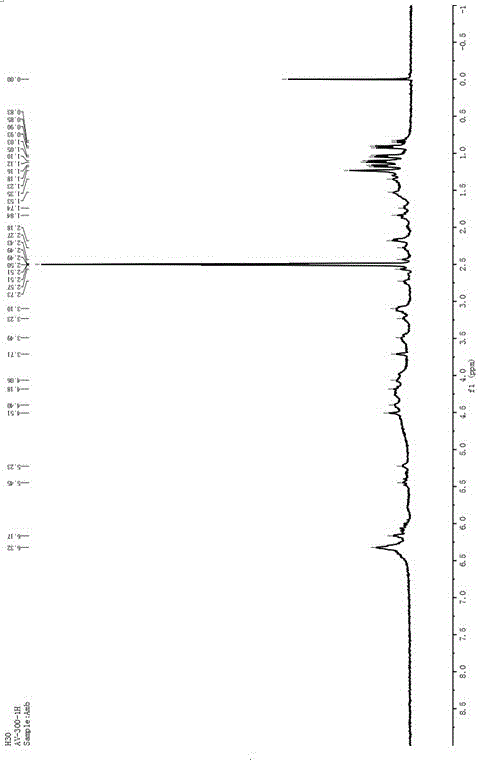

[0047] Example 2: Preparation of composite micelles of polyethylene glycol 2000-phosphatidylethanolamine and amphotericin B (molar ratio is 4:1)

[0048] Weigh 0.8mg of amphotericin B and 10mg of polyethylene glycol 2000-phosphatidylethanolamine and dissolve in 10ml of methanol-dimethylsulfoxide (1:1), remove the organic solvent by rotary evaporation under reduced pressure in a water bath at 50°C, and add phosphoric acid 10 ml of buffer salt was hydrated for 20 minutes, filtered through a 0.22 μm microporous membrane, 20 mg of mannitol was added as a freeze-drying protective agent, and freeze-dried. Reconstituted with water for injection, the encapsulation rate was 99.5%, the drug loading was 7.4%, and the particle size was 60.03nm.

Embodiment 3

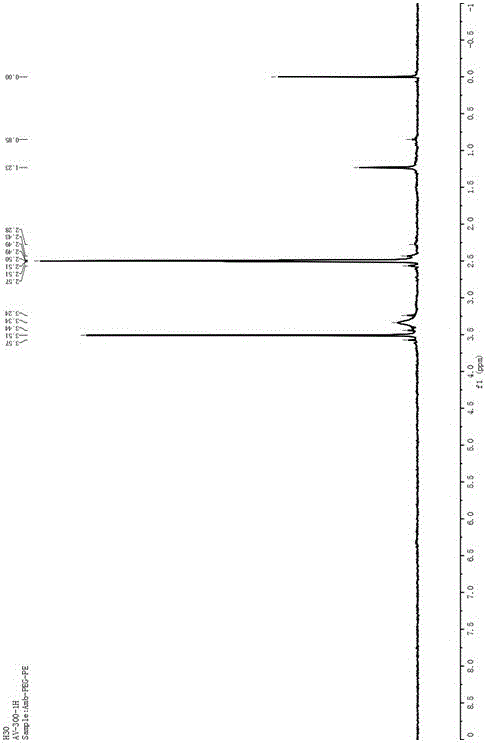

[0049] Example 3: Preparation of composite micelles of polyethylene glycol 4000-phosphatidylethanolamine and amphotericin B (molar ratio is 0.5:1)

[0050] Weigh 6.6mg of amphotericin B and 10mg of polyethylene glycol 4000-phosphatidylethanolamine and dissolve it in 18ml of methanol, remove the organic solvent by rotary evaporation under reduced pressure in a 60°C water bath, add 10ml of distilled water to hydrate for 15 minutes, and pass through a 0.22μm micropore Membrane filtration to obtain complex micelles. It was measured that the encapsulation efficiency was 98.7%, the drug loading capacity was 39.8%, and the particle size was 62.02nm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com