Graphene preparation method

A technology of graphene and graphite, which is applied in the field of graphene preparation, can solve the problems of graphene structure damage and low yield, and achieve the effect of simple operation and high yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

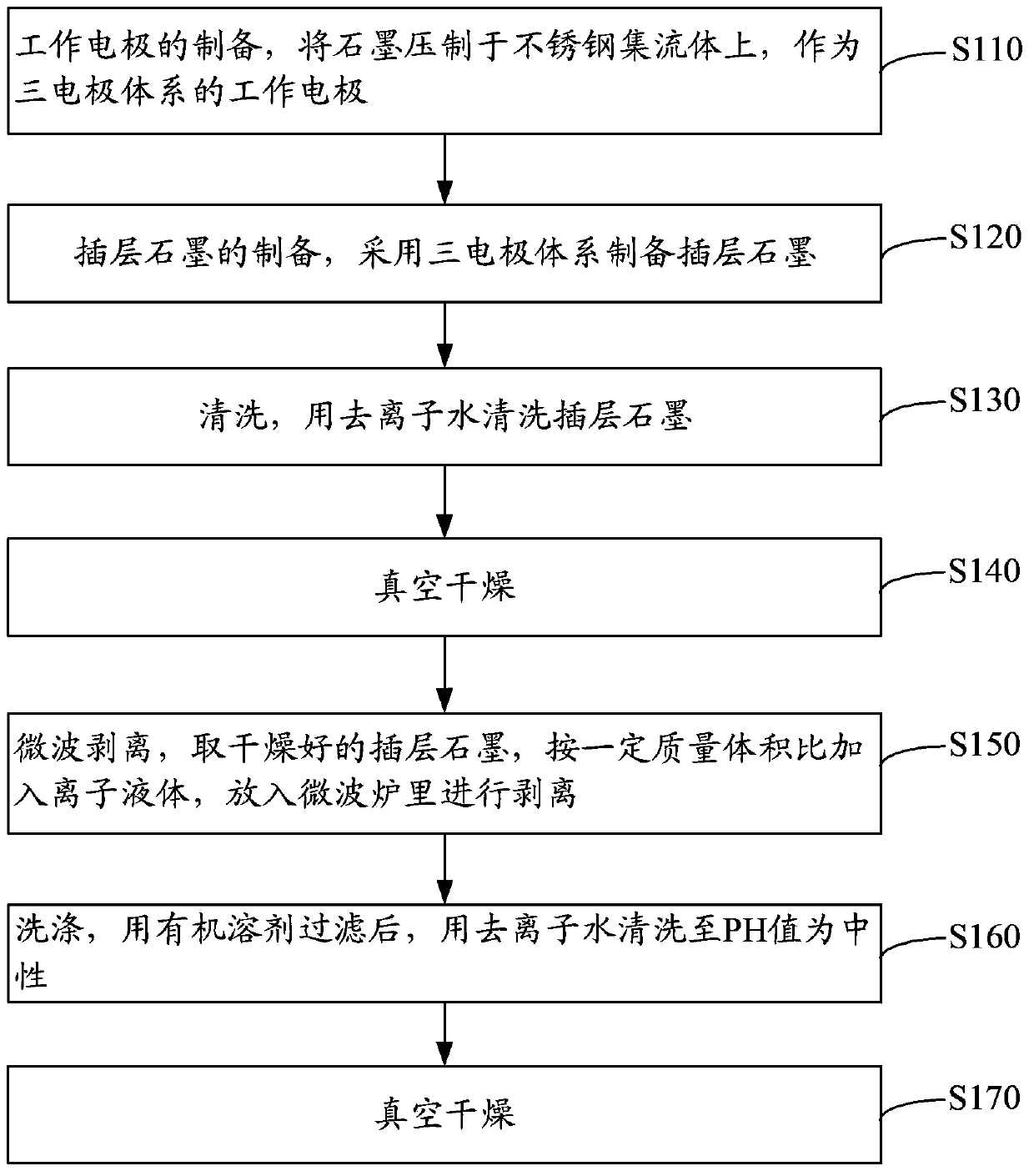

[0025] Such as figure 1 Shown, the preparation method of the graphene of one embodiment, comprises the steps:

[0026] Step S11 0: preparation of the working electrode, pressing graphite on the stainless steel current collector as the working electrode of the three-electrode system.

[0027] Graphite and binder are placed on the current collector, and then pressed into a working electrode of the three-level system with a mold. The current collector is preferably a stainless steel current collector.

[0028] Graphite can be graphite commonly used in this field, preferably natural flake graphite or artificial graphite.

[0029] Preferably, the counter electrode of the three-electrode system is a lead plate, and the reference electrode is Hg / Hg 2 SO 4 .

[0030] Step S120: preparation of intercalated graphite, using a three-electrode system to prepare intercalated graphite.

[0031] Intercalated graphite was prepared using a three-electrode system. The preparation method i...

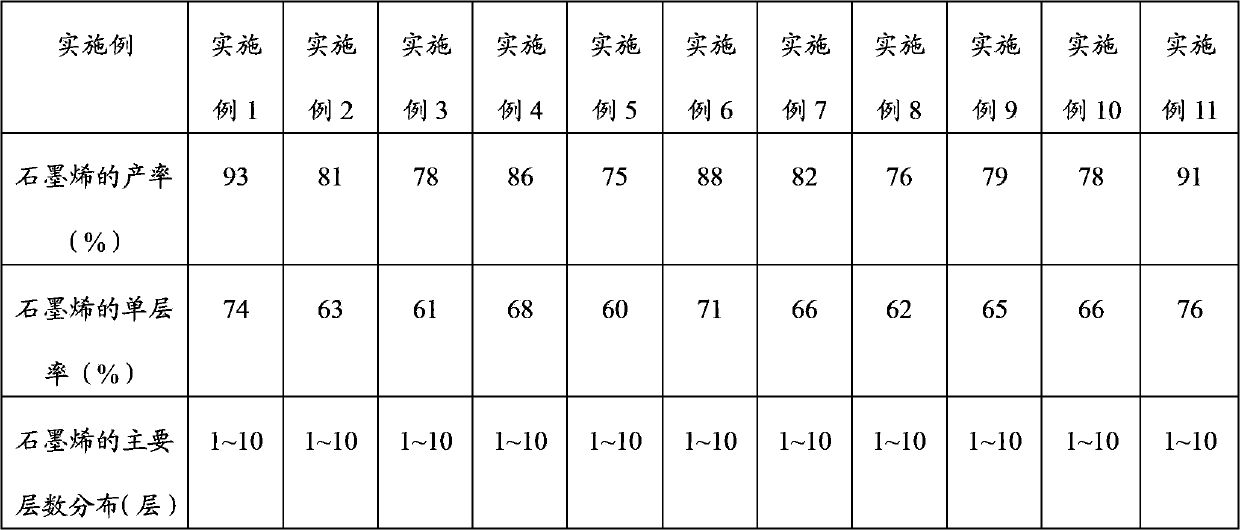

Embodiment 1

[0060] The preparation of the graphene of the present embodiment is as follows:

[0061] (1) Preparation of intercalated graphite: use stainless steel sheet as the current collector, place about 2g of natural flake graphite on the current collector, and press it with a mold to obtain the working electrode. The graphite is pressed into a size of 75×40×7mm 3 Graphite sheet, with lead plate as counter electrode, Hg / Hg 2 SO 4 As a reference electrode, formic acid as the electrolyte, put the three electrodes into the electrolytic cell, and completely soak in the electrolyte; at room temperature, the current density is 5mA / cm 2 React for 20 hours, filter, wash with deionized water, and dry at 60° C. for 24 hours in a vacuum oven to obtain intercalated graphite.

[0062] (2) Take 1g of intercalated graphite and add it to the EtMeImBF 4 In the ionic liquid container, place the container in a microwave oven with a power of 2000 watts and peel off for 1 minute to obtain a reaction so...

Embodiment 2

[0066] The preparation of the graphene of the present embodiment is as follows:

[0067] (1) Preparation of intercalated graphite: use stainless steel sheet as the current collector, place about 2g of artificial graphite on the current collector, and press it with a mold to obtain the working electrode. The graphite is pressed into a size of 75×40×7mm 3 Graphite sheet, with lead plate as counter electrode, Hg / Hg 2 SO 4 As a reference electrode, acetic acid as the electrolyte, put the three electrodes into the electrolytic cell, and completely soaked in the electrolyte; at room temperature, the current density is 20mA / cm 2 React for 10 hours, filter, wash with deionized water, and dry at 70° C. for 20 hours in a vacuum oven to obtain intercalated graphite.

[0068] (2) Take 1 g of intercalated graphite and add it to EtMeImN(CF 3 SO 2 ) 2 In the container of the ionic liquid, the container is placed in a microwave oven with a power of 1000 watts and peeled off for 10 minute...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com