Method and apparatus for producing lipids through microalgae culture

A microalgae cultivation and microalgae technology, applied in the field of biofuel preparation, can solve the problems not involved in the photosynthesis of microalgae and the monitoring of lipid production and separation process, and achieve low capital investment and operation costs, occupying an area of Effect of small, high lipid concentrations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

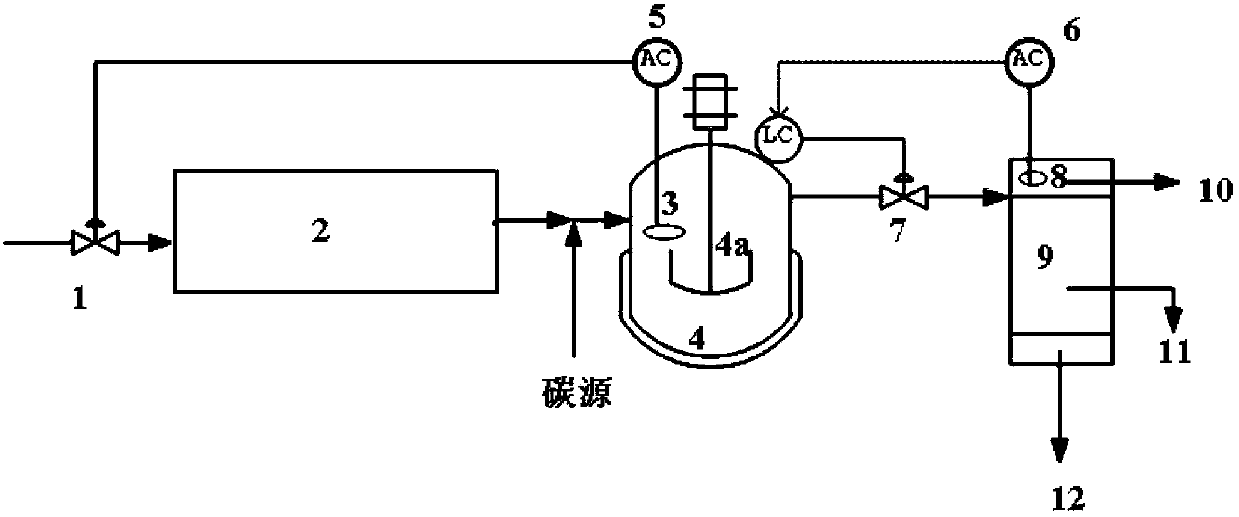

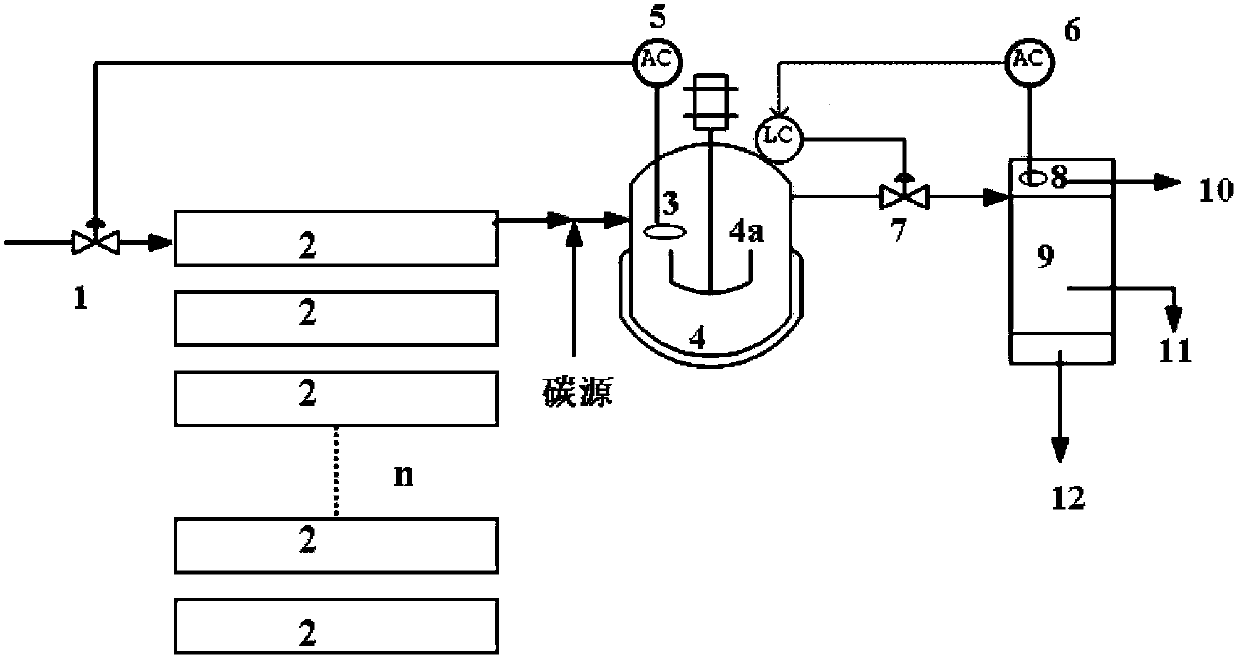

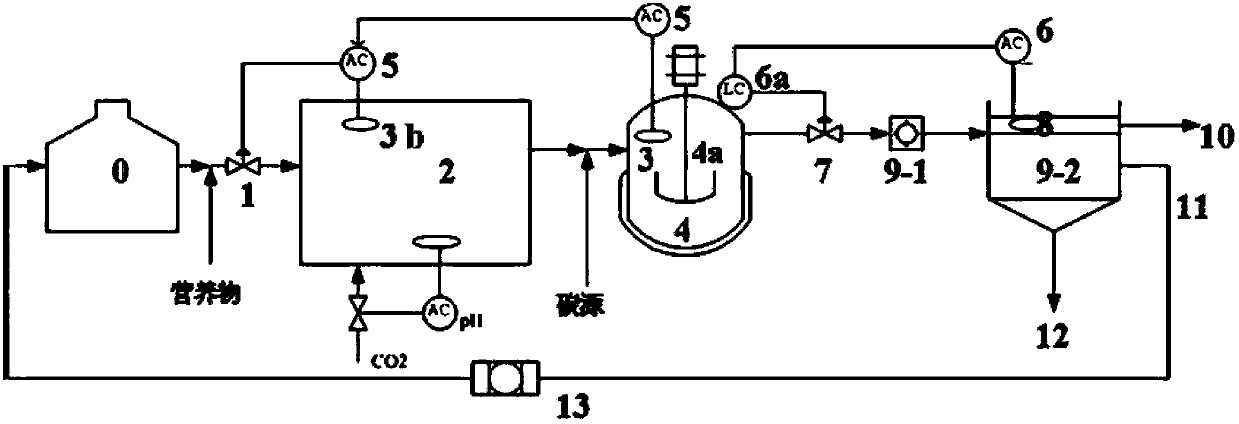

[0066] Embodiment 1. The parameter design of culture system

[0067] Controlled variables (CVs) can be selected from cell concentrations in photoautotrophic and photoheterotrophic reactors, lipid concentrations in photoheterotrophic reactors, and nutrient (preferably N) concentrations in photoheterotrophic reactors. In the example of the present invention, the system had a lipid yield of 30 tons / ha-year, corresponding to a dry weight yield of microalgae of 60 tons / ha-year. Table 1 summarizes the parameters and nominal operating points for this method. For ease of collection and downstream processing, 2kg / m is preferred 3 cell concentration and 50% lipid concentration.

[0068] Table 1. Design parameters of the culture system

[0069] parameters

Embodiment 2

[0070] Embodiment 2. Determination of the best culture point

[0071] The optimal culture point is dependent on the specific microalgae species and can be determined from batch culture experiments for lipid production. Examples of the present invention use Chlorella vulgaris. The first stage of cultivation is carried out photoautotrophically in a photoautotrophic reactor, ideally at the optimal operating point; the second stage of cultivation is carried out in a photoheterotrophic reactor at its optimal operating point at different carried out in the way of raising. This approach achieves high growth rates and high lipid concentrations of the microalgae. The control system of the present invention ensures that the cultivation process runs under optimal conditions without external interference.

[0072] Figure 4 For microalgae growth and lipid accumulation curves in batch mode, arrows indicate the optimal operating point for continuous culture. Such as Figure 4 It was s...

Embodiment 3

[0073] Embodiment 3. Method model and computer simulation

[0074] Process models and computer simulations aid in process development and control system design. The microalgae cultivation method and control system proposed by the present invention can be verified by computer simulation. Some model parameters were obtained from laboratory results of the freshwater green alga Chlorella vulgaris FACHB-31 (FACHB-Collection). In BG11 medium, sodium nitrate (nitrogen source) was chosen as the limiting nutrient, while other nutrients were in excess. Table 1 lists the design parameters of the culture system.

[0075] During the simulation, it is preferable to have a constant culture volume V 1 The photoautotrophic reactor operates as a chemostat. Input and output have the same volumetric flow rate F 1 , get the dilution ratio D=F 1 / V 1 .

[0076] d X 1 dt = ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com