Small microbial electrolysis cell and application thereof

A microbial electrolytic cell, small-scale technology, applied in the field of water treatment, can solve problems such as difficulty in finding aeration devices, influence of experimental results, uneven aeration, etc., and achieve good experimental results, simple structure, and convenient use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

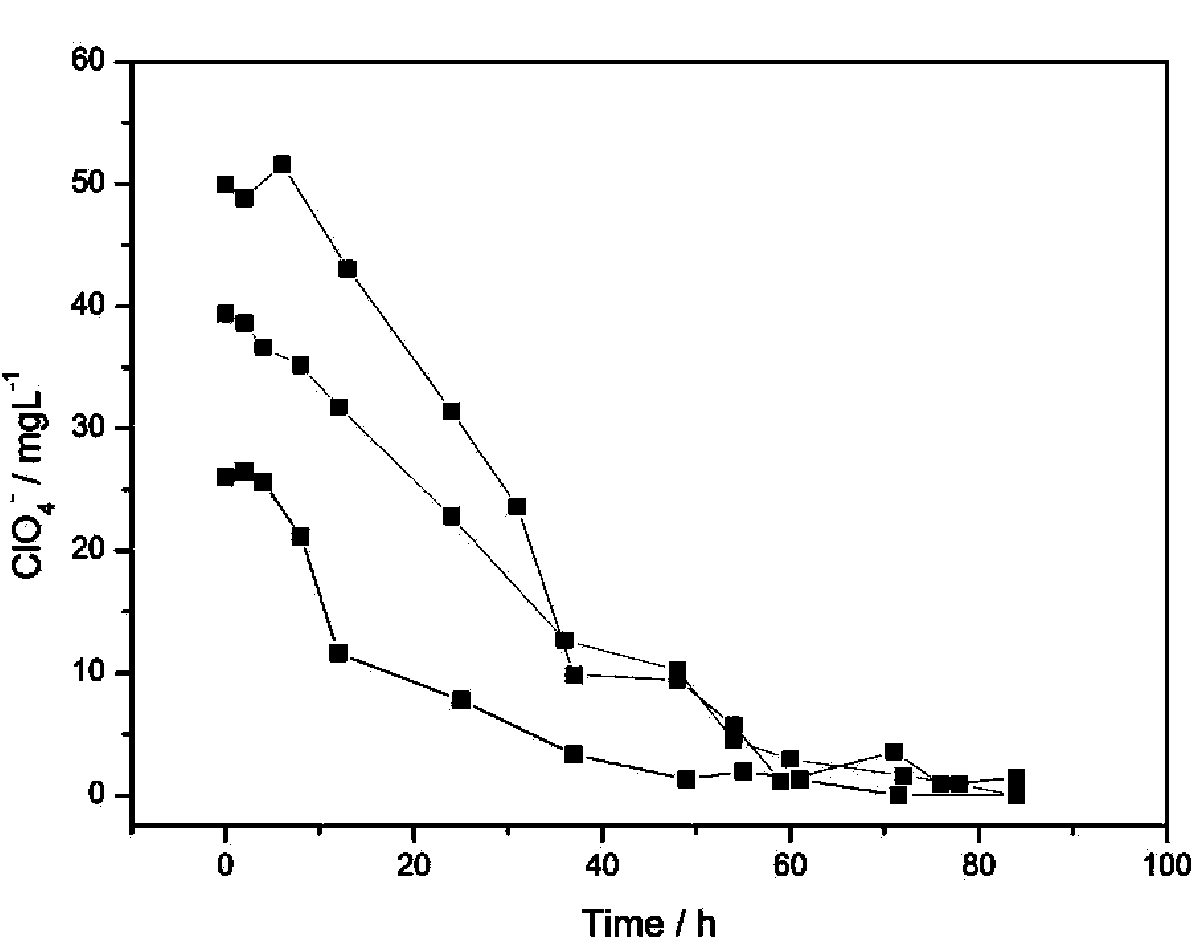

Embodiment 1

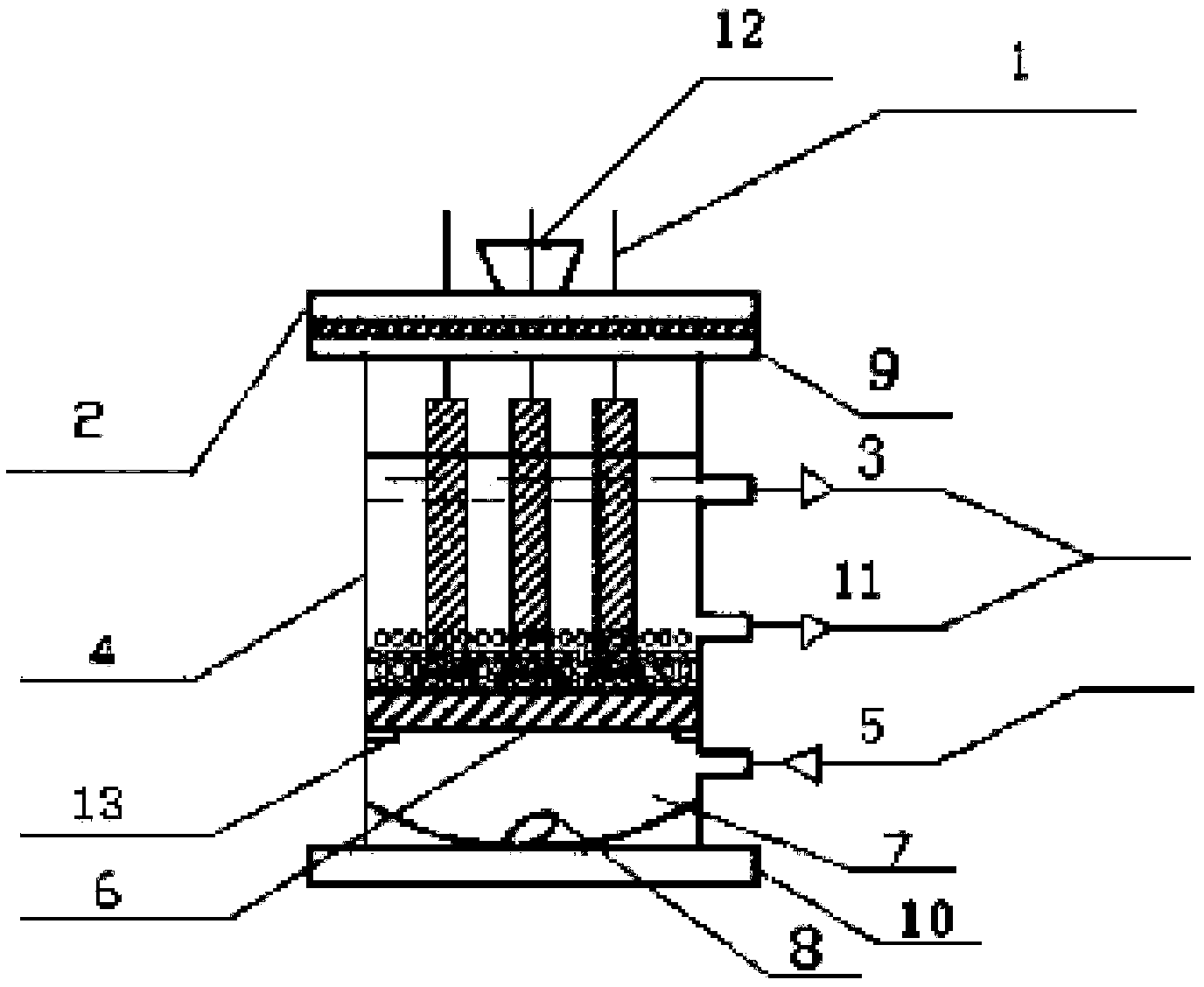

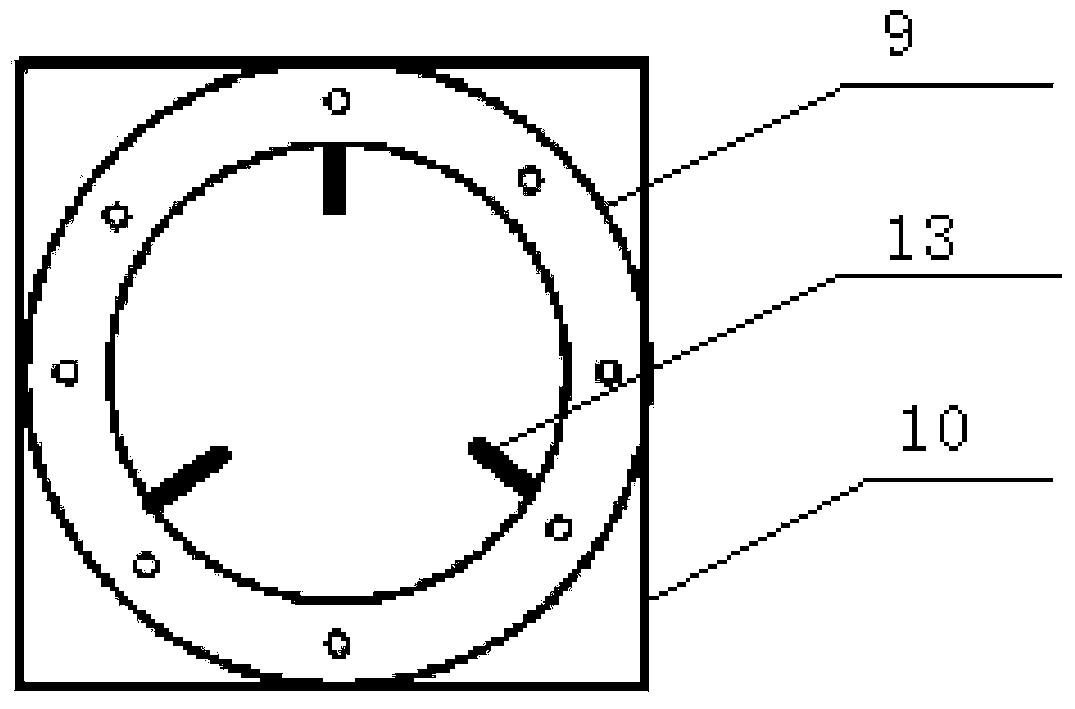

[0035] Such as figure 1 , figure 2Shown, a kind of small-scale microbial electrolytic cell, the structure of this electrolytic cell comprises flange 2, electrode 1, copper rod, microbial electrolytic cell reactor 4, aeration plate 6 and ion stirrer 8, wherein, microbial electrolytic cell reactor 4 is a hollow cylindrical container, the bottom edge of the cylindrical container is set as an outwardly extending base 10, the top of the cylindrical container is open, and the edge of the opening is set as an outwardly extending boss 9, and the flange 2 is passed through the bolt It is fixedly connected with the boss 9, and the center of the flange 2 is provided with a through hole, and a circle of electrode holes penetrating the flange is arranged outside the through hole, and the electrodes include 3 polyaniline graphite electrodes and 3 ordinary graphite electrodes, and the polyaniline graphite electrodes are Negative electrode, ordinary graphite electrode is positive electrode,...

Embodiment 2

[0037] Such as figure 1 , image 3 with Figure 4 Shown, a kind of small-sized microbial electrolytic cell, its structure is as shown in embodiment 1, and difference is: the bottom of cylindrical container is equipped with stirring tank 7, and stirring tank 7 is the arc-shaped container that the center portion is sunken downwards. The advantage of this design is that the stirrer 8 can be placed in the stirring tank 7, which relatively increases the thickness of the bottom of the reactor of the microbial electrolytic cell, and avoids the damage of the bottom of the reactor caused by the stirring of the stirrer 8 for a long time.

Embodiment 3

[0039] Such as figure 1 with figure 2 Shown, a kind of small-scale microbial electrolytic cell, its structure is as shown in embodiment 2, difference is: the diameter of the electrode hole on the flange 2 is 0.5mm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com