A kind of preparation method of precipitation hardening copper alloy

A precipitation hardening, copper alloy technology, applied in the field of alloys, can solve problems such as production efficiency defects, achieve the effects of improving production efficiency, excellent mechanical properties and electrical conductivity, and shortening heat treatment time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-6, and comparative example 1

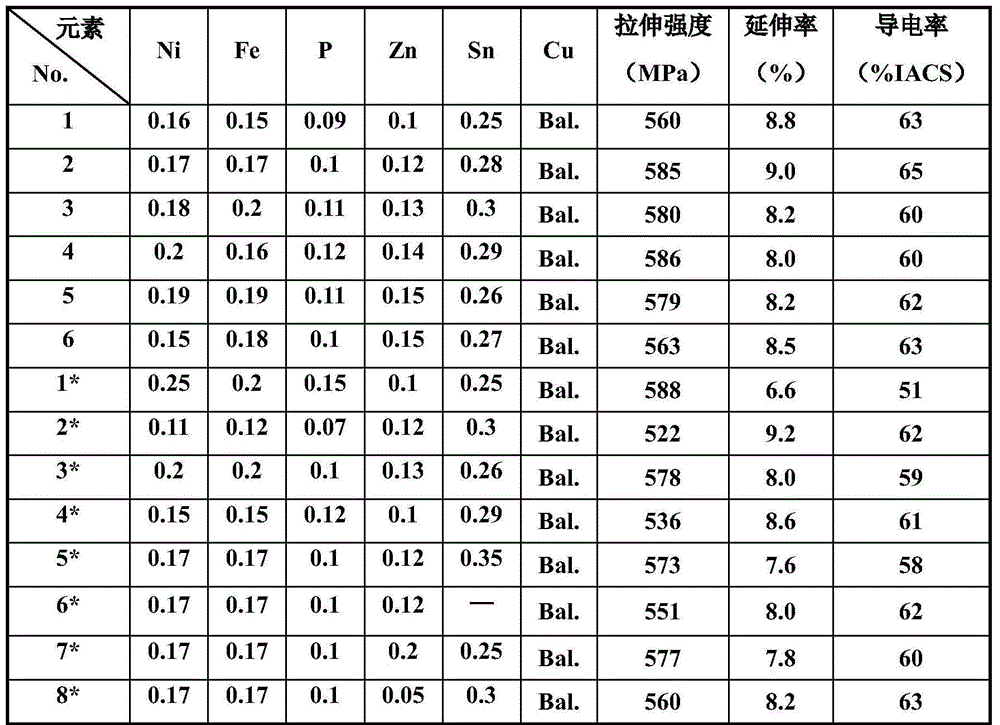

[0020] Examples 1-6, and comparative examples 1*-8*:

[0021] One, batching: mix and get raw material with the weight percentage shown in Table 1, and described raw material is the powder that purity is 99.99% oxygen-free copper and purity is each alloying element of 99.9%;

[0022] 2. Melting: Melting the prepared raw materials in a high-frequency furnace under a nitrogen protective atmosphere. The smelting is to first mix Cu, Zn, and Sn into the furnace, raise the temperature to 1240°C and continue stirring to melt The body is fully mixed, then Ni, Fe and P are added, continue to heat up to 1300°C and keep warm for smelting, after smelting, cast to obtain a Ф30mm, 200mm long copper alloy ingot;

[0023] 3. Hot rolling processing: After heating the copper alloy ingot to 960°C, perform 6 passes of hot rolling processing to 8mm, and the final rolling temperature is controlled at 740°C;

[0024] 4. Cold-rolled processing: After the hot-rolled copper alloy is milled to remove sc...

Embodiment 7-10

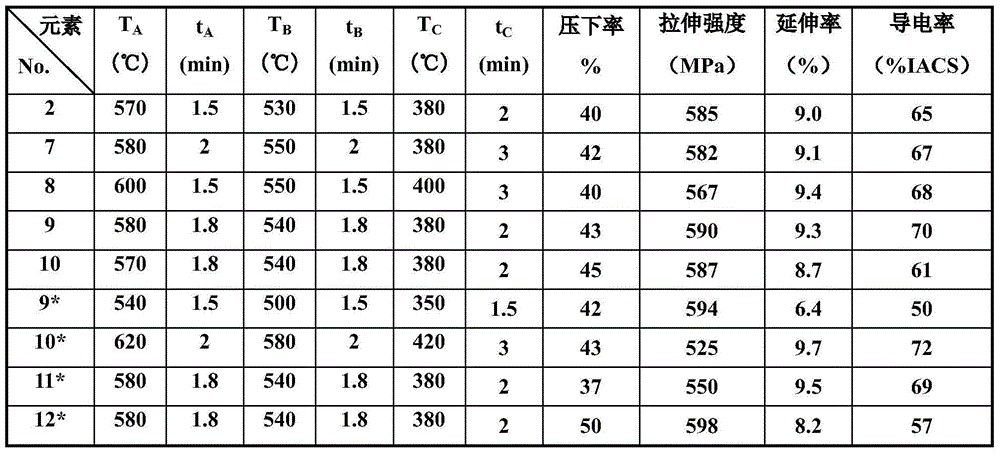

[0029] Examples 7-10, and Comparative Examples 9*-20*, the composition of the alloy is the same as Example 2, the first annealing temperature and time (A), the last two annealing temperatures and time (B), the final annealing Refer to Table 2 for the preparation process parameters such as temperature and time (C), cold rolling reduction rate and so on.

[0030] Table 2

[0031]

[0032] It can be seen from the results in Table 2 that the temperature of the first annealing, intermediate annealing and final annealing should not be too high, otherwise the strength of the copper alloy will not meet the requirements, but it should not be too low, too low to achieve the effect of annealing, As a result, the processability and electrical conductivity cannot meet the requirements. At the same time, considering the influence of intermediate cold rolling, the temperature of the first annealing should be set higher than the temperature of the intermediate annealing, and the temperatur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com