Ultrapure phosphine analysis method and apparatus thereof

An ultra-pure phosphine and analysis device technology, which is applied in measurement devices, analysis materials, material separation, etc., can solve the problems of long analysis period, complex gas path, large dead volume, etc., to reduce analysis time and short analysis period. , quantitative and accurate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

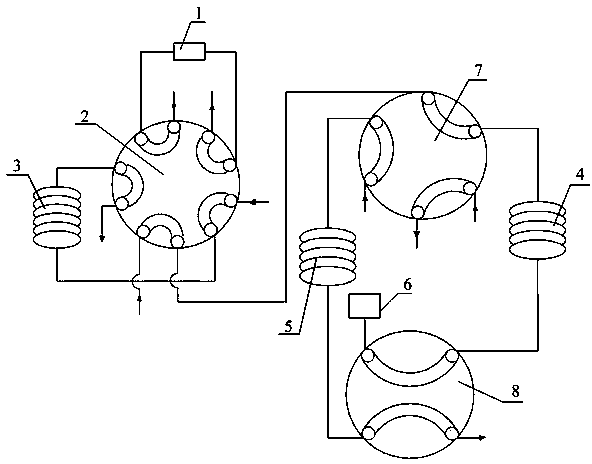

[0021] like figure 1 As shown, an analysis device for ultrapure phosphine includes a pre-separation column 3, a first analysis column 4, a second analysis column 5, a ten-way valve 2, a six-way valve 7 and a four-way valve 8, and a ten-way valve 2 Two of the ports of the ten-way valve 2 are respectively connected to the inlet and outlet of the quantitative tube 1, two of the ports of the ten-way valve 2 are connected to the inlet and outlet of the pre-separation column 3, and two of the ports of the ten-way valve 2 are connected to the intake pipe respectively. Two of the ports of the ten-way valve 2 are respectively connected to the carrier gas pipeline, one of the ports of the ten-way valve 2 is connected to the venting pipeline, one of the ports of the ten-way valve 2 is connected to one of the ports of the six-way valve 7, and the six Two of the ports of the through valve 7 are respectively connected to the carrier gas pipeline, one of the ports of the six-way valve 7 is c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com