Integrated engineering system for purifying flue gas by LSCO (low-temperature selectivity catalytic oxygen)

A catalytic oxidation and selective technology, applied in chemical instruments and methods, separation methods, air quality improvement, etc., can solve the problems of secondary pollution, high cost, large investment, etc., to reduce the concentration of particulate matter and small one-time investment , good reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

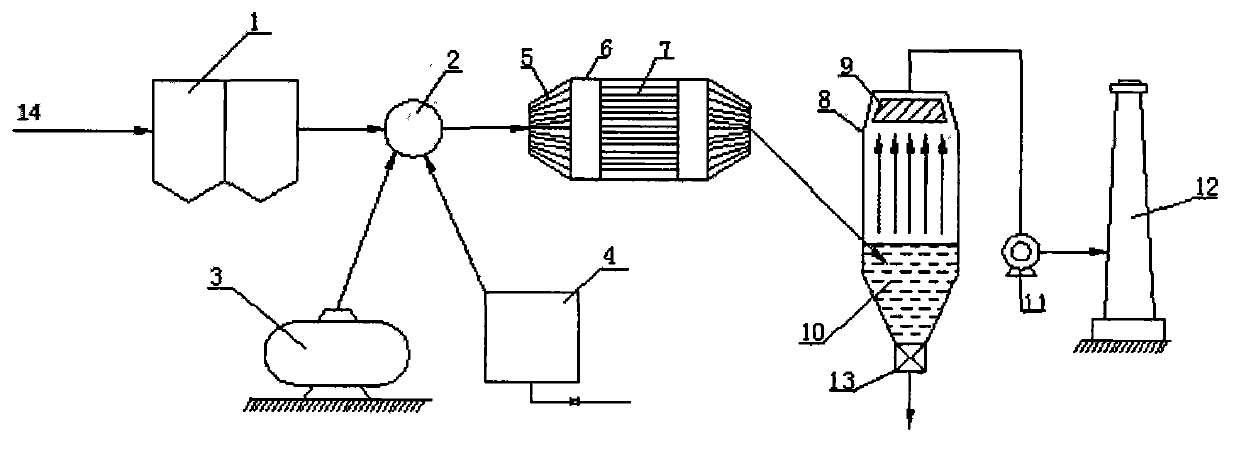

[0021] The LSCO low-temperature selective catalytic oxidation integrated flue gas purification engineering system consists of gas mixer, SCO catalytic oxidation tower, integrated desulfurization, denitrification absorption tower and corresponding supply system, such as compressed air, ammonia water and other absorbent storage and transportation The supply system is composed of the flue gas which is dedusted by the dust collector 1 and mixed with the mixed gas composed of compressed air 3 and accelerator gas 4 ejected from the gas mixer 2 and enters the static mixer 5 for further mixing in the catalytic oxidation tower 6. NO in flue gas is oxidized to NO under the action of catalyst 7 2 and other NO x As the flue gas enters the bubbling absorption tower 8 and reacts with the absorbing liquid 10 to generate corresponding nitrate and nitrite, at the same time the SO in the flue gas 2 It is also absorbed together, as well as solid particles and other substances such as Hg, etc., ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com