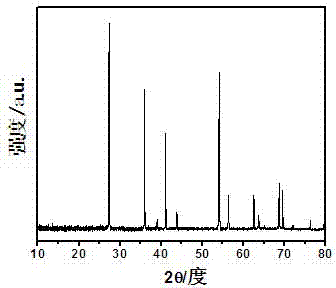

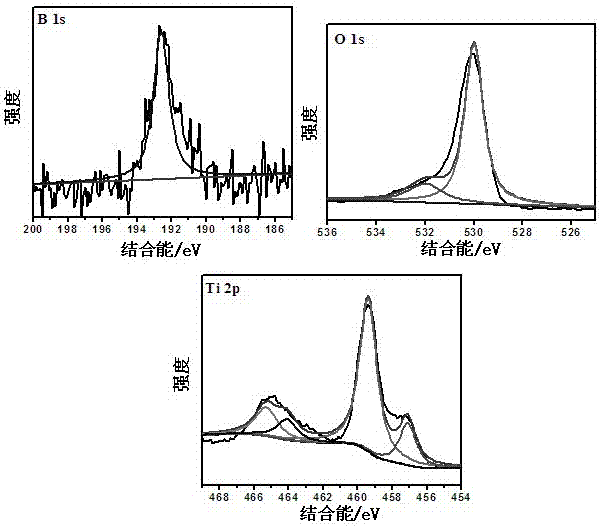

Preparation method of rutile type boron-doped titania (B-TiO2) microsphere with exposed high energy crystal face {001}

A rutile type, titanium boride technology, applied in chemical instruments and methods, chemical/physical processes, physical/chemical process catalysts, etc., can solve the problems of poor dispersion of doping elements, uneven stress, limited and other problems, Achieve the effect of avoiding the influence of morphology and stability, uniform size, and controllable doping amount

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

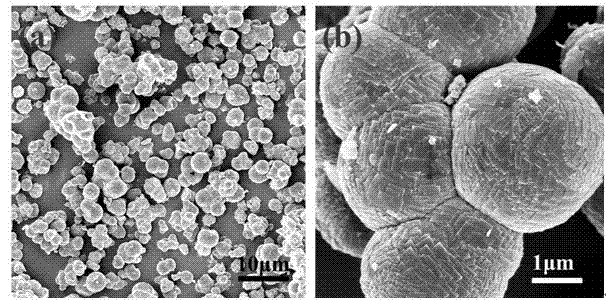

Embodiment 1

[0029] Add 500 mg of titanium boride (TiB, 99%) to 70 ml of hydrochloric acid solution containing 0.015 mol / L sodium fluoride in a 250 ml beaker, where the concentration of hydrochloric acid is 1.0 mol / L, stir vigorously for 30 min, then Transfer to a 100 ml lined tetrapolyethylene hydrothermal reaction kettle, put it into a constant temperature drying oven at 200 °C, and keep the reaction for 24 h under solvothermal conditions. After the reaction, it was naturally cooled to room temperature, washed three times with distilled water and absolute ethanol, and the product was vacuum-dried in a drying oven at 70 °C for 12 h. B-TiO prepared by this step 2 The diameter of the microspheres is about 3 μm.

Embodiment 2

[0031]Add 1000 mg of titanium boride (TiB, 99%) to 70 ml of hydrochloric acid solution containing 0.015 mol / L sodium fluoride in a 250 ml beaker, where the concentration of hydrochloric acid is 1.5 mol / L, stir vigorously for 15 min, then Transfer to a 100 ml lined tetrapolyethylene hydrothermal reaction kettle, put it into a constant temperature drying oven at 200 °C, and keep the reaction for 18 h under solvothermal conditions. After the reaction, it was naturally cooled to room temperature, washed three times with distilled water and absolute ethanol, and the product was vacuum-dried in a drying oven at 80 °C for 12 h. B-TiO prepared by this step 2 The diameter of the microspheres is about 3.8 μm.

Embodiment 3

[0033] Add 800 mg of titanium boride (TiB, 99%) to 70 ml of hydrochloric acid solution containing 0.015 mol / L sodium fluoride in a 250 ml beaker, where the concentration of hydrochloric acid is 2.0 mol / L, stir vigorously for 40 min, then Transfer to a 100 ml lined PTFE hydrothermal reaction kettle, put it into a constant temperature drying oven at 200 °C, and keep the reaction for 20 h under solvothermal conditions. After the reaction, it was naturally cooled to room temperature, washed three times with distilled water and absolute ethanol, and the product was vacuum-dried in a drying oven at 75 °C for 18 h. B-TiO prepared by this step 2 The diameter of the microspheres is about 4.2 μm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com