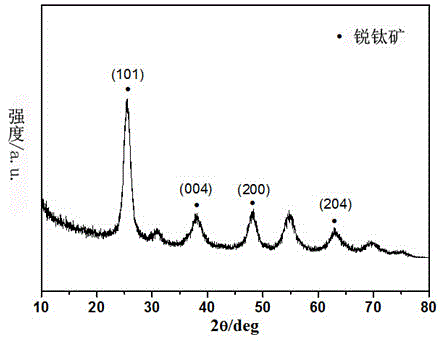

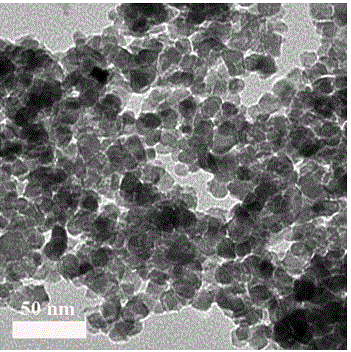

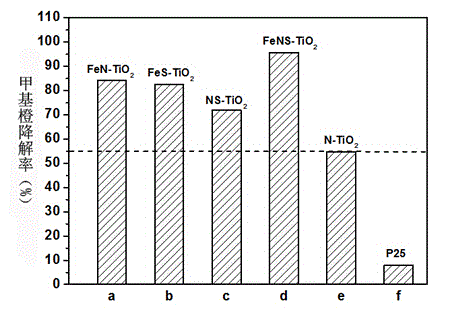

Preparation method of anatase nano-titanium dioxide powder modified via codoping of iron element with other two non-metallic elements

A nano-titanium dioxide, non-metallic element technology, applied in the field of photocatalytic materials, can solve the problems of uneven product morphology, low photocatalytic activity, poor stability, etc., to avoid the influence of morphology and stability, and achieve high catalytic activity. , the effect of uniform size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046] A preparation method of iron, nitrogen and sulfur three elements co-doped modified anatase nano-titanium dioxide powder: comprising the following steps:

[0047] In a small beaker, add 4 mL of alkylphenol ethoxylate (OP-10), 6 mL of n-butanol (C 4 h 9 OH), 20mL cyclohexane (C 6 h 12 ), 2 mL butyl titanate (Ti(OC 4 h 9 ) 4 , stir evenly to obtain a clear mixture A, in another beaker, add 0.0921 g FeCl 3 ·6H 2 O, 0.0304 g NH 4 Cl, and 0.0432 g thiourea, add 4 mL 0.1 M hydrochloric acid, add 4 mL alkylphenol polyoxyethylene ether (OP-10), 6 mL n-butanol (C 4 h 9 OH), 20 mL cyclohexane (C 6 h 12 ), stir evenly to obtain a clear mixed solution B, slowly drop the mixed solution B into the mixed solution A, and stir while dripping to obtain a clear mixed solution C, and then transfer the mixed solution C to a 100 mL liner poly Put it in a vinyl fluoride hydrothermal reaction kettle, put it into a drying oven, and keep a constant temperature of 160 °C for 4 h un...

Embodiment 2

[0051] A preparation method of iron, nitrogen and sulfur three elements co-doped modified anatase nano-titanium dioxide powder: comprising the following steps:

[0052] In a small beaker, add 4 mL of alkylphenol ethoxylate (OP-10), 6 mL of n-butanol (C 4 h 9 OH), 20mL cyclohexane (C 6 h 12 ), 2 mL butyl titanate (Ti(OC 4 h 9 ) 4 , stir evenly to obtain a clear mixture A, in another beaker, add 0.0921 g FeCl 3 ·6H 2 O, 0.0304 g NH 4 Cl, and 0.0432 g thiourea, add 4 mL 0.1 M hydrochloric acid, add 4 mL alkylphenol polyoxyethylene ether (OP-10), 6 mL n-butanol (C 4 h 9 OH), 20 mL cyclohexane (C 6 h 12 ), stir evenly to obtain a clear mixed solution B, slowly drop the mixed solution B into the mixed solution A, and stir while dripping to obtain a clear mixed solution C, and then transfer the mixed solution C to a 100 mL liner poly Put it in a vinyl fluoride hydrothermal reaction kettle, put it in a drying oven, and keep a constant temperature of 180 °C for 2 h unde...

Embodiment 3

[0057] A preparation method of iron, nitrogen and sulfur three elements co-doped modified anatase nano-titanium dioxide powder: comprising the following steps:

[0058] In a small beaker, add 4 mL of alkylphenol ethoxylate (OP-10), 6 mL of n-butanol (C 4 h 9 OH), 20mL cyclohexane (C 6 h 12 ), stir well to obtain a clear mixture A, in another beaker, add 2 mL of titanium tetrachloride (TiCl 4 ), 0.0921 g FeCl 3 ·6H 2 O, 0.0304 g NH 4 Cl, and 0.0432 g thiourea, 4 mL 0.1 M hydrochloric acid, add 4 mL alkylphenol polyoxyethylene ether (OP-10), 6 mL n-butanol (C 4 h 9 OH), 20 mL cyclohexane (C 6 h 12 ), stir evenly to obtain a clear mixed solution B, slowly drop the mixed solution B into the mixed solution A, and stir while dripping to obtain a clear mixed solution C, and then transfer the mixed solution C to a 100 mL liner poly Put it in a vinyl fluoride hydrothermal reaction kettle, put it in a drying oven, and keep a constant temperature of 180 °C for 2 h under sol...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com