Compound type semiconductor photocatalyst and preparation method thereof as well as photocatalytic system and hydrogen production method

A photocatalyst and semiconductor technology, applied in the field of catalysis, can solve the problems of complex catalyst preparation process, low catalyst catalytic activity, and high requirements for experimental instruments, and achieve the effects of cost reduction, catalyst stability and convenient operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0067] A method for reforming biomass and its derivatives with a photocatalytic system containing a composite semiconductor photocatalyst and preparing hydrogen, comprising the following steps:

[0068] Add 0.5 mg of G2-CdS complex to the Pyrex test tube, and then add 0.5 mL of nickel dichloride aqueous solution (original concentration 4.2×10 -3 mol L -1 , containing 0.5mg nickel dichloride hexahydrate), 5mL ethanol (original concentration 17.16mol L -1 , 20°C), adding ultrapure water to make the total volume constant to 10mL, and the measured pH value of the system was about 6.7. Make it in a sealed nitrogen atmosphere, and irradiate the test tube with a 500W high-pressure mercury lamp (400nm long-pass glass filter).

[0069] The composite catalyst can be seen to turn black during the irradiation process, and this color change indicates the assembly of metallic nickel onto G2-CdS. The catalytic hydrogen production efficiency of G2-CdSNi is 17.54μmol·h -1 ·mg -1 .

[007...

Embodiment 2

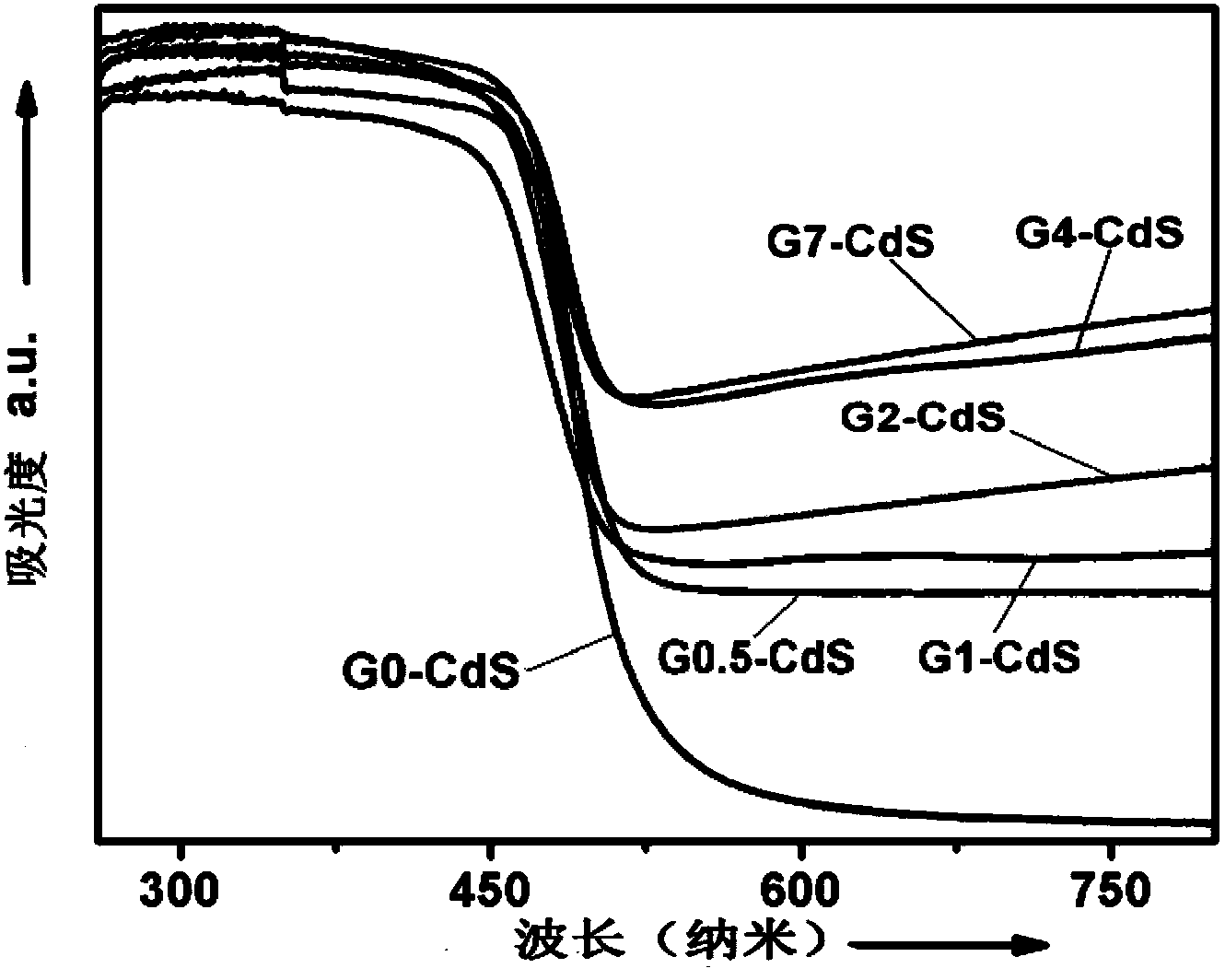

[0081] Comparison of hydrogen production by photocatalytic systems containing different mass fractions of graphene oxide:

[0082] The steps are the same as in Example 1, the difference is that graphene oxides of different masses are added to DMSO to generate Gx-CdS composites with different mass fractions of graphene.

[0083] Figure 10 It is the variation curve of hydrogen production volume over time for different Gx-CdSNi catalysts of Example 2. It can be seen from the figure that as the mass fraction of graphene oxide increases, the hydrogen production activity gradually increases. When the mass fraction of graphene is 2%, the catalytic activity of Gx-CdSNi is the highest.

Embodiment 3

[0085] A method for reforming biomass and its derivatives with a photocatalytic system containing a composite semiconductor photocatalyst and preparing hydrogen, comprising the following steps:

[0086] Step is with embodiment 1, and difference is: with 5ml methyl alcohol (original concentration 24.75mol L -1 , 20°C) instead of "5mL ethanol (original concentration 17.16mol L -1 , 20°C)".

[0087] Comparative example ④: Other conditions are the same as in Example 3, the difference is that G2-CdS is replaced by G0-CdS complex.

[0088] Figure 11 The catalysts of Example 3 and Comparative Example ④ are ultrasonically dispersed with ethanol and water and then dropped on the ultra-thin carbon film, and are observed under HRTEM. Among them, 11A is the product of G0-CdS irradiation, and 11B is the product of G2-CdS irradiation. It can be found that after illumination, the morphology of G0-CdSNi is the same as that of G0-CdS ( Figure 6 A) Compared with that, there is no obvious...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com