Copper pipe horizontal continuous casting gas shield crystallizer and method for preparing copper alloy pipe through copper pipe horizontal continuous casting gas shield crystallizer

A technology of horizontal continuous casting and gas shielding, which is applied in the field of copper alloy pipe production equipment and technology, can solve the problems of increasing the friction force of the tube blank, poor production continuity, and large metal loss, and achieves improved quality, reduction of attached crops, and use of Life extension effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

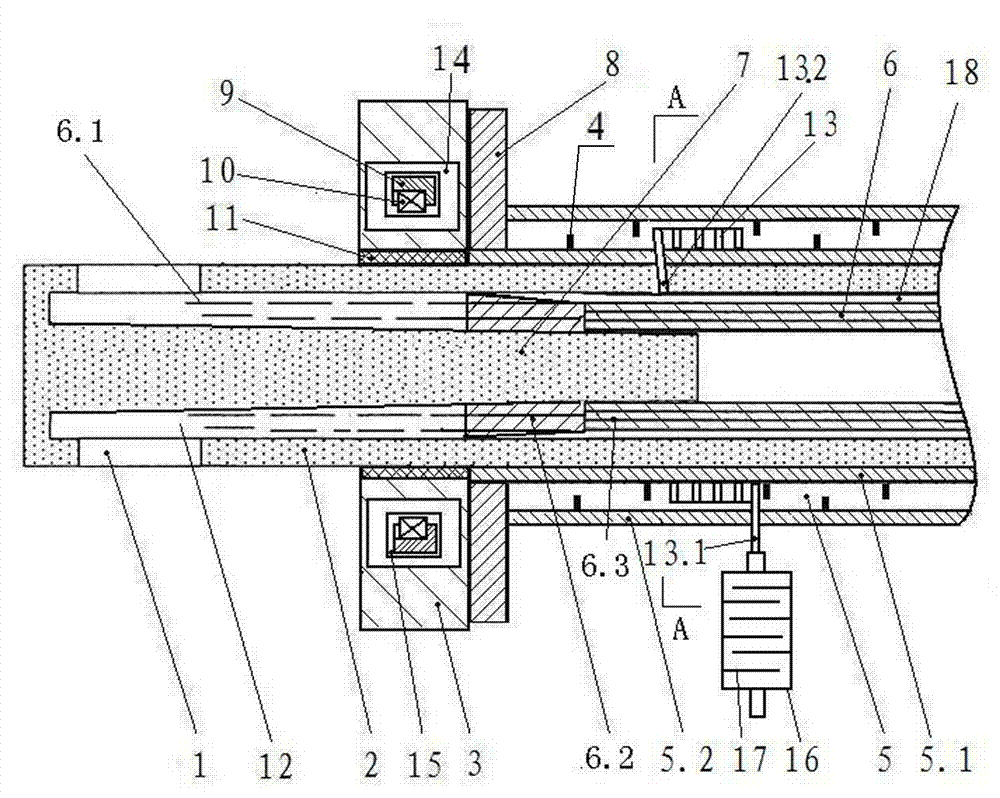

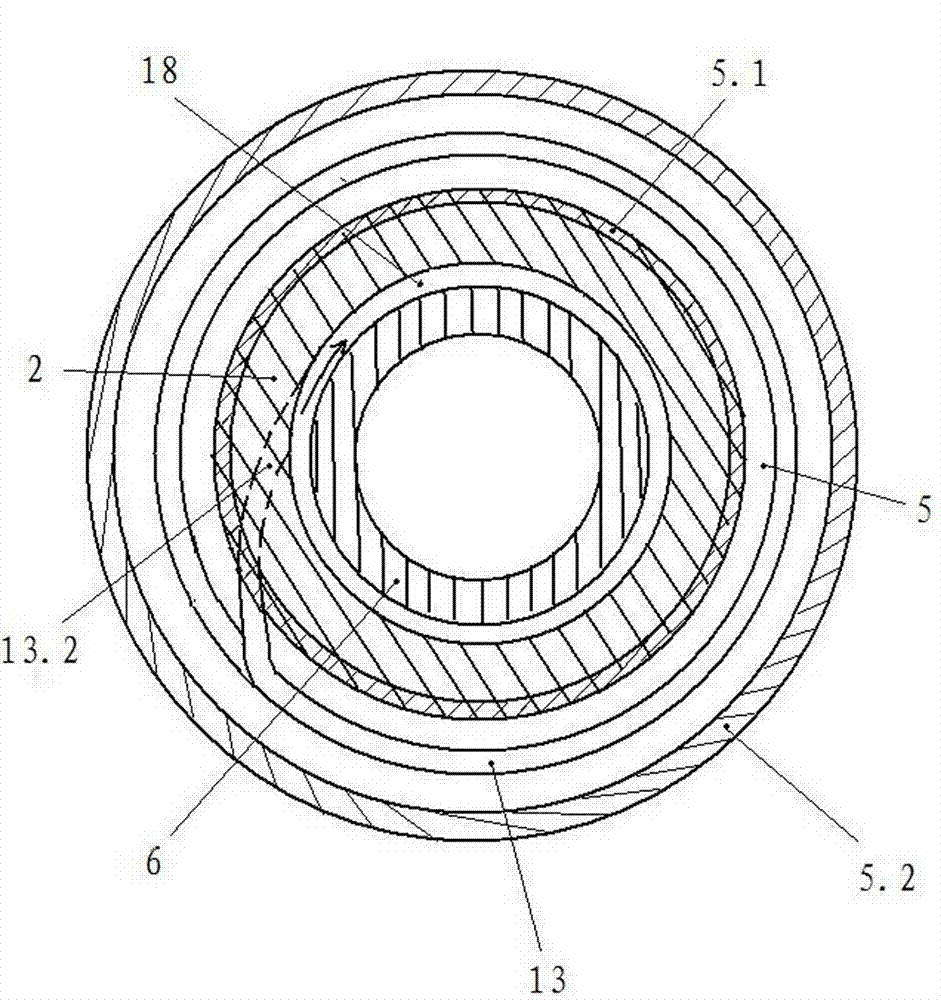

[0018] see figure 1 , a copper tube horizontal continuous casting gas shielded crystallizer, comprising an external graphite jacket 2 and an internal graphite core rod 7, and the graphite jacket 2 and the graphite core rod 7 form an annular inner cavity 12; the bottom of the graphite jacket 2 is provided with The liquid inlet 1, the middle part of the graphite jacket 2 are successively set with a pressure plate 3, a flange 8 and a cooling copper sleeve 5, and the cooling copper sleeve is provided with baffles 4 arranged at intervals; between the pressure plate 3 and the graphite jacket 2 15-20mm thick refractory protective cover 11, the refractory protective cover is preferably silicon carbide brick, corundum brick protective cover or refractory mud cover; the inner side of the pressure plate 3 is provided with a stainless steel cooling water jacket 14, and the stainless steel cooling water jacket 14 is provided with an electromagnetic Occurrence chamber 15, a plurality of ele...

Embodiment 2

[0021] A gas-protected crystallizer for horizontal continuous casting of copper tubes. On the basis of Embodiment 1, in order to reduce magnetic flux leakage and increase the magnetic induction intensity in the working area, the electromagnetic generating chamber 15 is also provided with a ring-shaped magnetic gathering frame.

Embodiment 3

[0023] A copper tube horizontal continuous casting gas-protected crystallizer, on the basis of embodiment 1 or 2, the refractory material protective cover wherein preferably adopts the refractory material made by the following method: Portland cement of 15-25 parts by weight, 20 -25 parts by weight of fly ash, 18-22 parts by weight of silicon carbide, 30-40 parts by weight of alumina, 3-5 parts by weight of vermiculite powder, 2-4 parts by weight of zirconia, 1-2 parts by weight Sodium oxide and 1-2 parts by weight of graphite are mixed into a mixed powder, and then a binder (such as aluminum dihydrogen phosphate) accounting for 5-6% of the total weight of the mixed powder is added. After being formed by a hydraulic press, it is dried and sintered to obtain To obtain a finished product, the temperature of sintering is controlled at 1550-1580° C. for 2-3 hours. Experiments have proved that the refractory protective sleeve obtained by this method has high thermal stability, high...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Current intensity | aaaaa | aaaaa |

| Size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap