A kind of preparation method of porous graphene

A porous graphene and graphene technology, applied in the field of materials engineering, can solve the problems of restricting the subsequent application of new graphene-derived materials, complex processes, and small pore size range of porous graphene, so as to be suitable for large-scale industrial production and simple process , the effect of a wide range of pore size distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

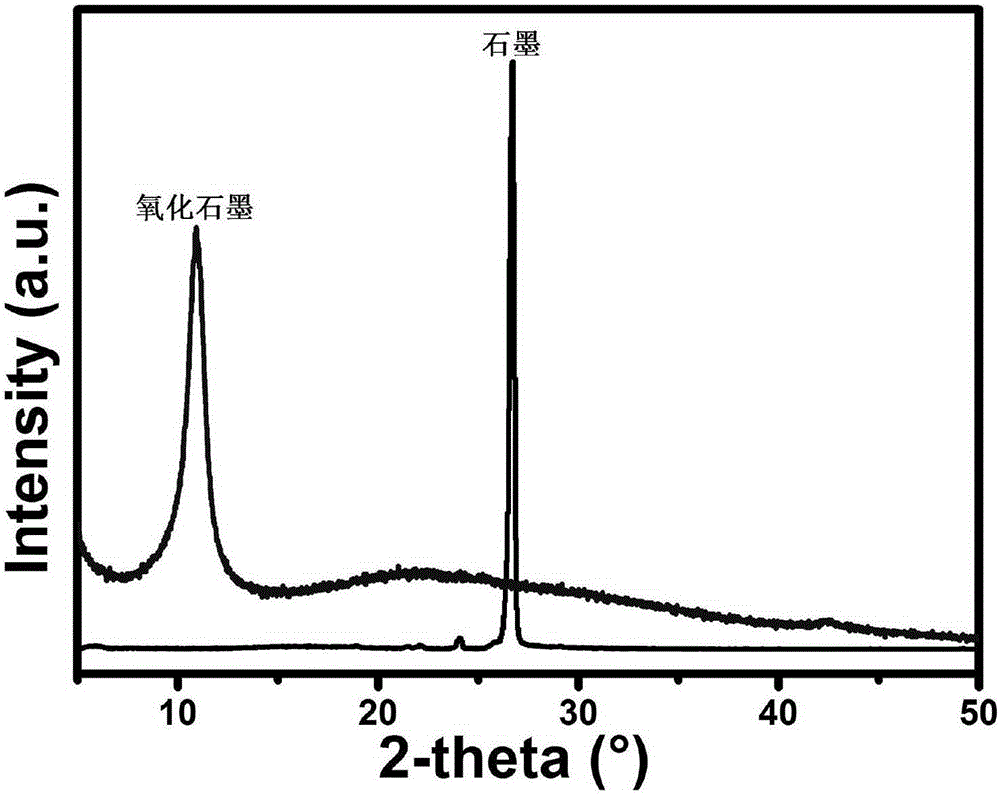

[0023] 1) Preparation of porous graphene oxide:

[0024] Take 0.02g graphite oxide and prepare 100ml solution with a concentration of 0.2g / L, and sonicate it at 20kHz frequency for 30min to obtain graphene oxide (GO) solution. Then the solution was centrifuged at 10000rpm to collect the GO colloid at the bottom, and the GO colloid was mixed with 200ml of 70% nitric acid solution, ultrasonicated for 30min at 15kHz frequency, and then deionized water was added. The centrifuge was washed repeatedly at the same speed. The system was washed to a pH of 4 and freeze-dried to obtain a porous graphene oxide solid with nanopores.

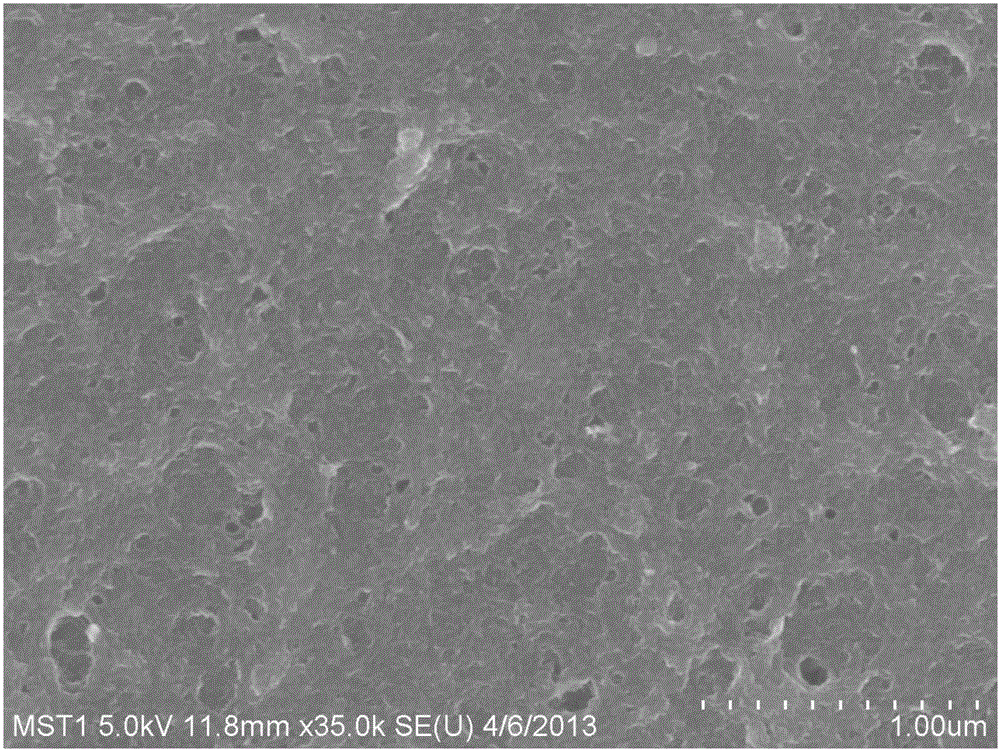

[0025] 2) Preparation of porous graphene:

[0026] The porous graphene oxide solid obtained in step 1 was prepared into a 1L solution with a mass concentration of 0.01g / L, and 0.05g sodium borohydride was added to the graphene oxide solution, and reacted at a temperature of 100°C for 6h to obtain a porous The graphene dispersion liquid is filtered, washed, and fre...

Embodiment 2

[0029] 1) Preparation of porous graphene oxide:

[0030] Take 0.015g of graphite oxide, prepare 1.5L of a solution with a concentration of 0.01g / L, and sonicate it at a frequency of 40kHz for 60min to obtain a graphene oxide (GO) solution. Then the solution was centrifuged at 12000rpm to collect the bottom GO colloid, mix the GO colloid with 15ml of 40% hydrofluoric acid solution, sonicate at 28kHz frequency for 60min, then add deionized water, and centrifuge repeatedly at the same speed Wash, wash the system to a pH of 5, and freeze-dry to obtain graphene oxide solid with nanopores.

[0031] 2) Preparation of porous graphene:

[0032] The porous graphene oxide solid obtained in step 1 was prepared into a 20ml solution with a mass concentration of 0.5g / L, 0.2g ascorbic acid was added to the graphene oxide solution, and reacted at a temperature of 80°C for 10 minutes to obtain porous graphite The olefin dispersion liquid is filtered, washed, and freeze-dried to obtain a porous graph...

Embodiment 3

[0034] 1) Preparation of porous graphene oxide:

[0035] Take 0.3 g of graphite oxide, prepare 60 ml of a solution with a concentration of 5 g / L, and sonicate it for 100 min at a frequency of 50 kHz to obtain a graphene oxide (GO) solution. Then the solution was centrifuged at 15000rpm to collect the GO colloid at the bottom, and the GO colloid was mixed with 150ml of nitric acid solution with a mass concentration of 68%, sonicated at 60kHz for 120min, then added deionized water, and washed repeatedly at the same speed. The system was washed to a pH of 6, and freeze-dried to obtain graphene oxide solid with nanopores.

[0036] 2) Preparation of porous graphene:

[0037] The porous graphene oxide solid obtained in step 1 was prepared into a 50ml solution with a mass concentration of 5g / L, and 15ml hydrazine hydrate aqueous solution containing 0.25g hydrazine hydrate was added to the graphene oxide solution and reacted at a temperature of 50°C After 10 hours, a porous graphene disper...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electron mobility | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com