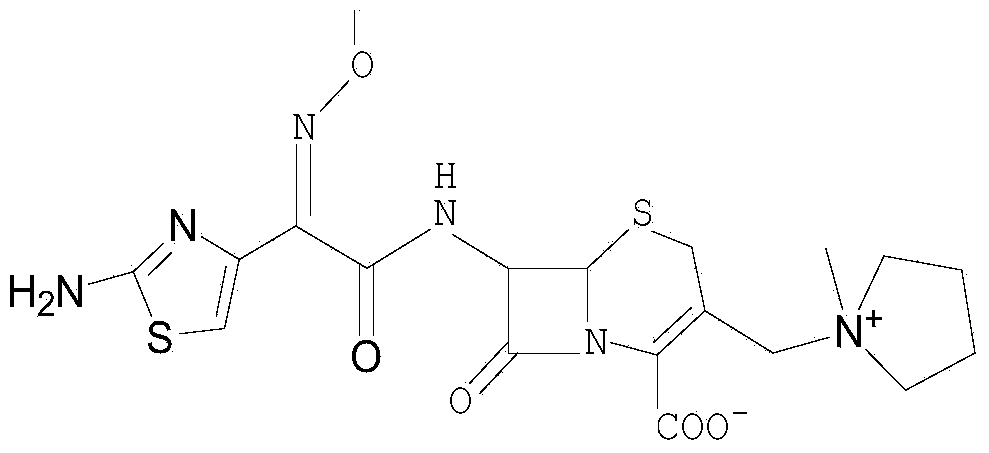

Refining method of high-purity cefepime dihydrochloride monohydrate

A technology of cefepime dihydrochloride and monohydrate, which is applied in the field of refining high-purity cefepime dihydrochloride monohydrate, and can solve the problems of products not meeting Chinese quality standards, cefepime with high water solubility, Unable to reduce water content and other issues, to achieve low loss, high purity, and low impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Add 5Kg of activated carbon to 500L of acetone, stir for 2h, filter through a filter tank equipped with a 0.01um high-precision filter element, and then cool to below 5°C for use. Add 5Kg of activated carbon to 300L of ethanol, stir for 2h, filter through a filter tank equipped with a 0.01um high-precision filter element, and then cool to below 5°C for use.

[0028] Cefepime internal salt 200Kg and 60Kg concentrated hydrochloric acid, 10Kg sodium bisulfite, 10KgEDTA-Na 2 Add to 900L methanol and heat up to 35℃ to dissolve, add 3Kg activated carbon and stir for 2h, filter through a filter tank equipped with a 0.01um high-precision filter element, transfer the filtrate to a crystallization tank and stir, add 100g seed crystals (cefepime hydrochloride) , Lower the temperature to below 5°C, add 100L of the above acetone dropwise for 3h, maintain the temperature at 0°C during the dropping process, and grow the crystals for 2h after the dropwise addition. After the crystal growt...

Embodiment 2

[0030] Add 8Kg of activated carbon to 800L of acetone, stir for 3h, filter through a filter tank equipped with a 0.01um high-precision filter element, and then cool to below 5°C for use. Add 8Kg of activated carbon to 600L of ethanol, stir for 3h, filter through a filter tank equipped with a 0.01um high-precision filter element, and then cool to below 5°C for use.

[0031] Mix 200Kg of cefepime internal salt and 50Kg of concentrated hydrochloric acid, 15Kg of sodium bisulfite, 15Kg of EDTA-Na 2 Add to 1000L methanol and heat up to 30℃ to dissolve, add 8Kg activated carbon and stir for 3h, filter through a filter tank equipped with a 0.01um high-precision filter element, transfer the filtrate to a crystallization tank and stir, add 200g seed crystals (cefepime hydrochloride) , The temperature is lowered to below 5°C, 200L of the above acetone is added dropwise, the dropping time is 5h, the temperature is maintained at 10°C during the dropping process, and the crystals are grown for...

Embodiment 3

[0033] Add 10Kg of activated carbon to 1000L of acetone, stir for 4h, filter through a filter tank equipped with a 0.01um high-precision filter element, and then cool to below 5°C for use. Add 10Kg of activated carbon to 600L of ethanol, stir for 4h, filter through a filter tank equipped with a 0.01um high-precision filter element, and then cool to below 5°C for use.

[0034] Cefepime internal salt 200Kg and 80Kg concentrated hydrochloric acid, 20Kg sodium bisulfite, 20KgEDTA-Na 2 Add to 1200L methanol and heat to 50℃ to dissolve, add 10Kg activated carbon and stir for 4h, filter through a filter tank equipped with 0.01um high-precision filter element, transfer the filtrate to a crystallization tank and stir, add 200g seed crystals (ceftepime hydrochloride) , Lower the temperature to below 5°C, add 400L of the above acetone dropwise for 6 hours, maintain the temperature at 5°C during the dropping process, and grow the crystals for 5 hours after the drop. After the crystal growth ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com