Multifunctional fluorine-containing microsphere as well as preparation method and application thereof

A multifunctional, microsphere technology, applied in water repellent addition, coating, iron oxide/iron hydroxide, etc., can solve the problems of poor washing resistance, complex process, high price, etc., and achieve good water dispersion. high performance, simple preparation method and good corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

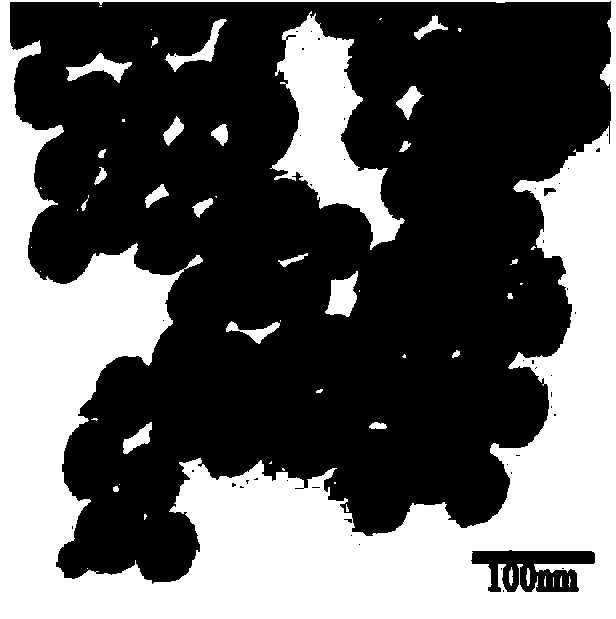

Embodiment 1

[0061] (1) Preparation of silica microspheres: Add 100ml of absolute ethanol and 3mL of ammonia water to a 250mL round-bottomed flask, then add 4mL of tetraethyl orthosilicate dropwise, react at 35°C for 24h, and wash the product with absolute ethanol After centrifuging and washing for three times, the obtained silica microspheres were subjected to freeze-vacuum drying, and the finally obtained silica microspheres had a particle size of 50±5nm.

[0062] (2) Synthesis of silica microspheres modified with mercaptosilane coupling agent: Add silica microspheres in anhydrous toluene, ultrasonically disperse for 30 minutes (ultrasonic power is 300W, temperature is 35°C), and then add silane Coupling agent, nitrogen deoxygenation for 40min, stirring reaction at room temperature for 24h, the reaction products were successively washed with acetone, toluene, and ethanol, and then vacuum-dried at room temperature for 24h to obtain modified silica microspheres, in which silica microspheres...

Embodiment 2

[0076] (1) Preparation of silica microspheres: Add 100ml of absolute ethanol and 5mL of ammonia water into a 250mL round-bottomed flask, then add 7mL of tetraethyl orthosilicate dropwise, react at 35°C for 24h, and wash the product with absolute ethanol After centrifuging and washing three times, the obtained silica microspheres were lyophilized and vacuum-dried, and the final particle size of the obtained silica microspheres was 110±5nm;

[0077] (2) Synthesis of silica microspheres modified with mercaptosilane coupling agent: In anhydrous toluene, add the silica microspheres prepared in step (1), and disperse them ultrasonically for 30 minutes (ultrasonic power is 300W, temperature is 35 ℃), then add a silane coupling agent, pass nitrogen gas to remove oxygen for 40 minutes, and stir at room temperature for 30 hours. The product is washed with acetone, toluene, and ethanol for several times, and then vacuum-dried at room temperature for 24 hours to obtain modified silica micr...

Embodiment 3

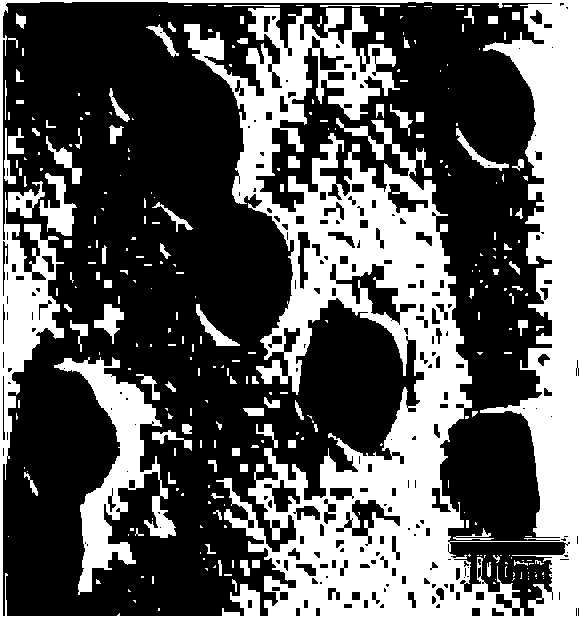

[0090] (1) Preparation of silica microspheres: Add 100ml of absolute ethanol and 7mL of ammonia water into a 250mL round bottom flask, then add 10mL of tetraethyl orthosilicate dropwise, react at 35°C for 24h, and then wash the product with absolute ethanol After centrifuging and washing for three times, the obtained silica microspheres were subjected to freeze-vacuum drying, and the finally obtained silica microspheres had a particle size of 300±5nm.

[0091] (2) Synthesis of silica microspheres modified with mercaptosilane coupling agent: In anhydrous toluene, add the silica microspheres prepared in step (1), and disperse them ultrasonically for 30 minutes (ultrasonic power is 300W, temperature is 35 ℃), then add silane coupling agent, pass nitrogen gas to remove oxygen for 40min, stir and react at room temperature for 48h, wash the product with acetone, toluene, and ethanol for several times, and then dry in vacuum at room temperature for 24h to obtain modified silica micros...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com