Propylene butene high melt strength polypropylene foam board or sheet and preparation method thereof

A high-melt-strength, foamed sheet technology, applied in the polymer field, can solve the problems of increasing low-molecular-weight random substances, high n-hexane extract, limited application scope, etc., to meet the requirements of food hygiene, and to achieve smooth self-skinning. , The effect of the process is easy to adjust

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

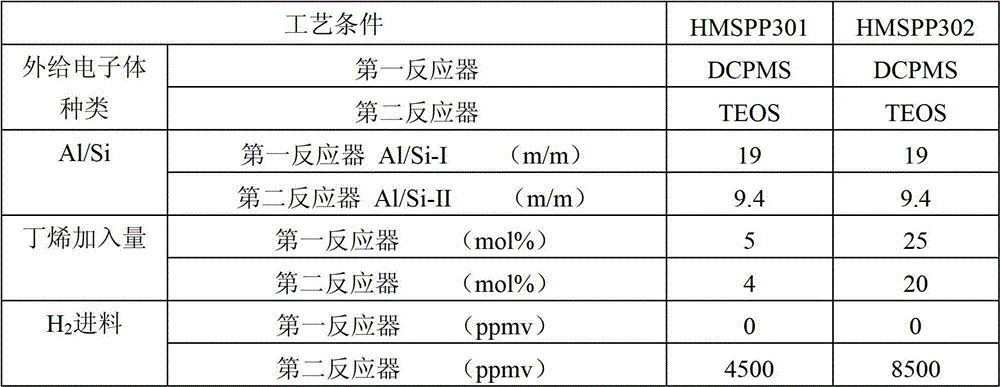

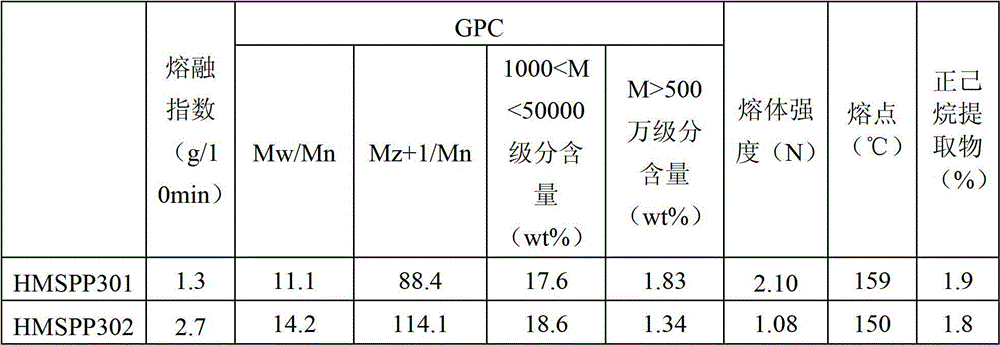

[0031] Preparation of matrix resin HMSPP301

[0032] The polymerization reaction was carried out on a polypropylene pilot plant. Its main equipment includes prepolymerization reactor, first loop reactor and second loop reactor.

[0033] Pre-polymerization reaction: the main catalyst (titanium-containing solid catalyst active component) is obtained by the method described in Example 1 of Chinese patent CN93102795, the Ti content is 2.4wt%, the Mg content is 18.0wt%, and the di-n-phthalic acid The butyl ester content is 13 wt%. The main catalyst, co-catalyst (triethylaluminum), and the first external electron donor (dicyclopentyldimethoxysilane, DCPMS) are pre-contacted at 10°C for 20 minutes, and then continuously added to the pre-polymerization reactor for pre-polymerization. In the polymerization reactor, the pre-polymerization is carried out in the environment of the propylene liquid phase bulk, the temperature is 15°C, and the residence time is about 4 minutes. Under this...

Embodiment 1~10

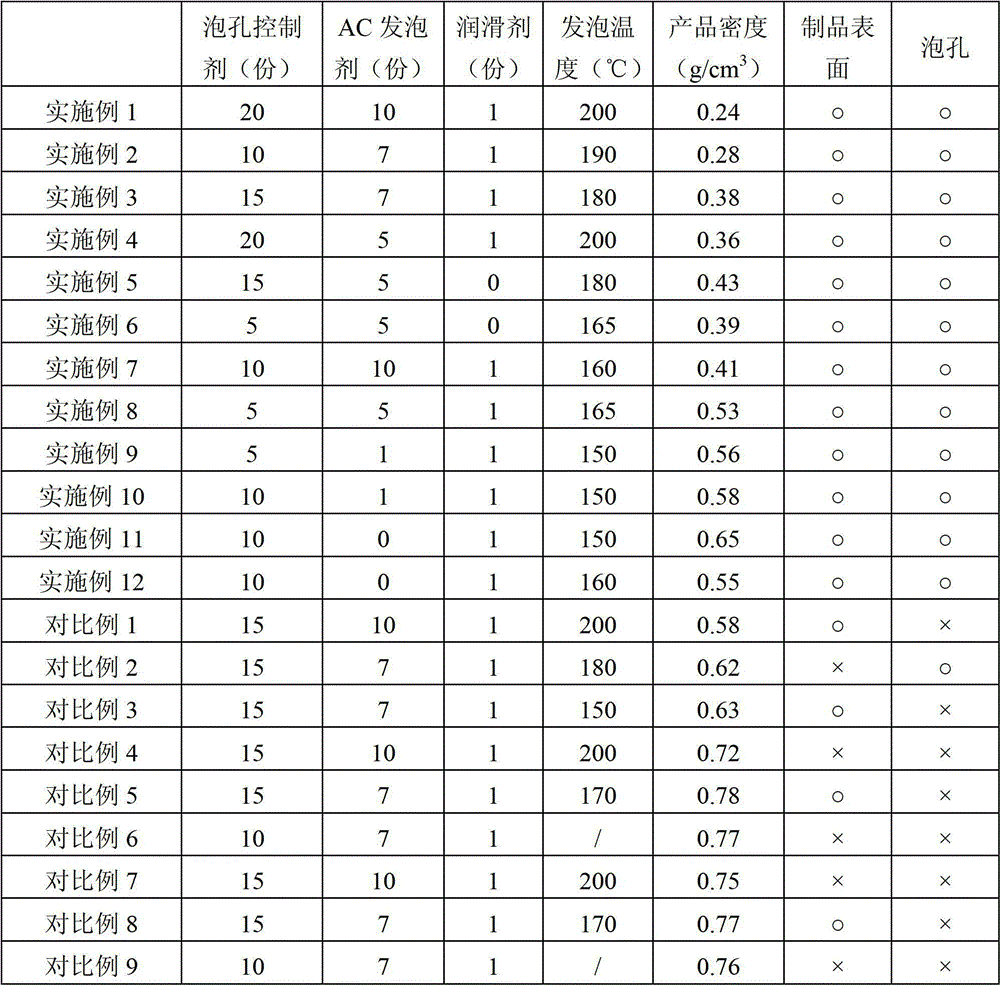

[0045] Put 100 parts by weight of high melt strength polypropylene HMSPP301 or HMSPP302, foaming agent (azodicarbonamide, namely industrial grade AC foaming agent), cell control agent (talc powder) and additives into a high-speed mixer at high speed After mixing for 1 minute, add the middle layer twin-screw, the torque is controlled at about 65%, and the speed is 10-170rpm. Among them, the additives include acid absorbing agent calcium stearate, antioxidant (calcium stearate with a weight ratio of 1:2:2, BASF antioxidant 1010 and antioxidant 168 compounded, accounting for 0.2 parts by weight in total) and Lubricant MB50-002 (high molecular weight polysiloxane), the weight parts of cell control agent, foaming agent and lubricant are shown in Table 3; the foaming temperature and the density of the product sheet are shown in Table 3, using specific GB / T1033 .1-2008 for density measurements. Examples 1~3 and 6~10 use high melt strength polypropylene HMSPP301, and Examples 4~5 use...

Embodiment 11

[0047] The remaining steps are the same as in Examples 1-10, and the specific data are shown in Table 3; only the blowing agent is changed from azodicarbonamide to 5 parts by weight of dinitrosopentamethylenetetramine.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com