Surfactant composition and preparation method thereof

A technology of surfactant and composition, applied in the field of surfactant composition and preparation thereof, can solve the problems of corrosion of equipment and pipelines, difficulty in demulsification, poor oil displacement efficiency, formation and oil well damage, etc., and achieves improved oil displacement. Efficiency, Enhanced Recovery, and Injury Avoidance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

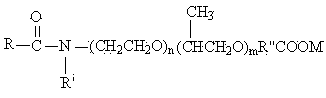

Image

Examples

Embodiment 1

[0028] Will C 5 h 11 COOCH 3 , Diethanolamine is added to the reaction kettle according to the molar ratio of 1:1.5, and 0.8% of the NaOH of the total weight of the aforementioned materials is added at the same time, at 100 o C reacted for 10 hours; Then add the required ethylene oxide, propylene oxide, at 200 o C reacted again for 1 hour; then follow C 5 h 11 COOCH 3 Add sodium chloroacetate at a molar ratio of 1:1 to carboxylation reagent, at 50 o C continued to react for 20 hours, and finally added hydrochloric acid to neutralize to pH<3, allowed to stand for separation, and added 30% NaOH aqueous solution to the oil phase for neutralization to obtain an anionic-nonionic surfactant.

[0029] Tetraethylammonium chloride and the anionic-nonionic surfactant prepared by the present invention were respectively dissolved in water, stirred for 30 minutes, and formulated into a 0.3% aqueous solution, and then the above-mentioned surfactant was mixed according to cationic:anio...

Embodiment 2

[0032] Will C 20 h 41 COOH and ethanolamine are added to the reaction kettle according to the molar ratio of 1:1.8, and 0.5% of the total weight of the aforementioned materials is added to the KOH at the same time, at 200 o C reaction 1 hour; Then add required ethylene oxide, propylene oxide, at 100 o C reacted again for 10 hours; then follow C 20 h 41 Add sodium chloroacetate at a molar ratio of COOH to carboxylation reagent of 1:1.5, at 80 o C continued to react for 8 hours, and finally added hydrochloric acid to neutralize to pH<3, allowed to stand for separation, and added 30% NaOH aqueous solution to the oil phase for neutralization to obtain an anionic-nonionic surfactant.

[0033] Tetrabutylammonium chloride and the anionic-nonionic surfactant prepared by the present invention were respectively dissolved in water, stirred for 30 minutes, and formulated into a 0.3% aqueous solution, and then the above-mentioned surfactant was mixed according to cationic: anionic-noni...

Embodiment 3

[0036] Will C 14 h 29 COOCH 3 , ethanolamine is added to the reactor according to the molar ratio of 1:1, and 15% of the KOH of the total weight of the aforementioned materials is added at the same time, at 160 o C reacted for 8 hours; Then add the required oxirane, propylene oxide, at 150 o C reacted again for 10 hours; then follow C 14 h 29 COOCH 3 Add Br(CH 2 ) 5 COOH, at 100 o C continued to react for 1 hour, finally added hydrochloric acid to neutralize to pH3 ) 2 The aqueous solution is neutralized to obtain anionic-nonionic surfactant.

[0037] Tetraoctyl ammonium chloride and the anionic-nonionic surfactant prepared by the present invention were dissolved in water respectively, stirred for 30 minutes, and formulated into a 0.3% aqueous solution, and then the above-mentioned surfactant was mixed according to cationic: anionic-nonionic surfactant The molar ratio of 1:1.4 was mixed evenly to obtain surfactant composition 3, whose composition and structure are sh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com