Lithium ion battery anode material and preparation method thereof

A technology for lithium-ion batteries and cathode materials, applied in battery electrodes, secondary batteries, circuits, etc., can solve the problems of poor chemical performance, low durability and cycle performance of lithium batteries, achieve excellent electronic conductivity, and improve charging. Potential, good compatibility effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0049] In a second aspect, an embodiment of the present invention provides a method for preparing the above-mentioned cathode material for a lithium-ion battery, comprising the following steps:

[0050] (1) Stir and disperse the coated raw material lithium source, N source, M source and the positive electrode active material to be coated in deionized water to make a precursor slurry;

[0051] The lithium source of the coating raw material is: one or more of lithium hydroxide, lithium carbonate, lithium nitrate, lithium chloride and lithium acetate;

[0052] The N source and M source are one or more of oxides, nitrates, chlorides and hydroxides containing N and M respectively;

[0053] The N is one or more of La, Al, Sr, Sc, Cr, Ba, Fe, Mo and Y; the M is one or more of Ta, Nb and V;

[0054] (2) roasting the obtained precursor slurry to obtain the lithium-ion battery cathode material coated with a fast ion conductor layer;

[0055] The composition of the fast ion conductor l...

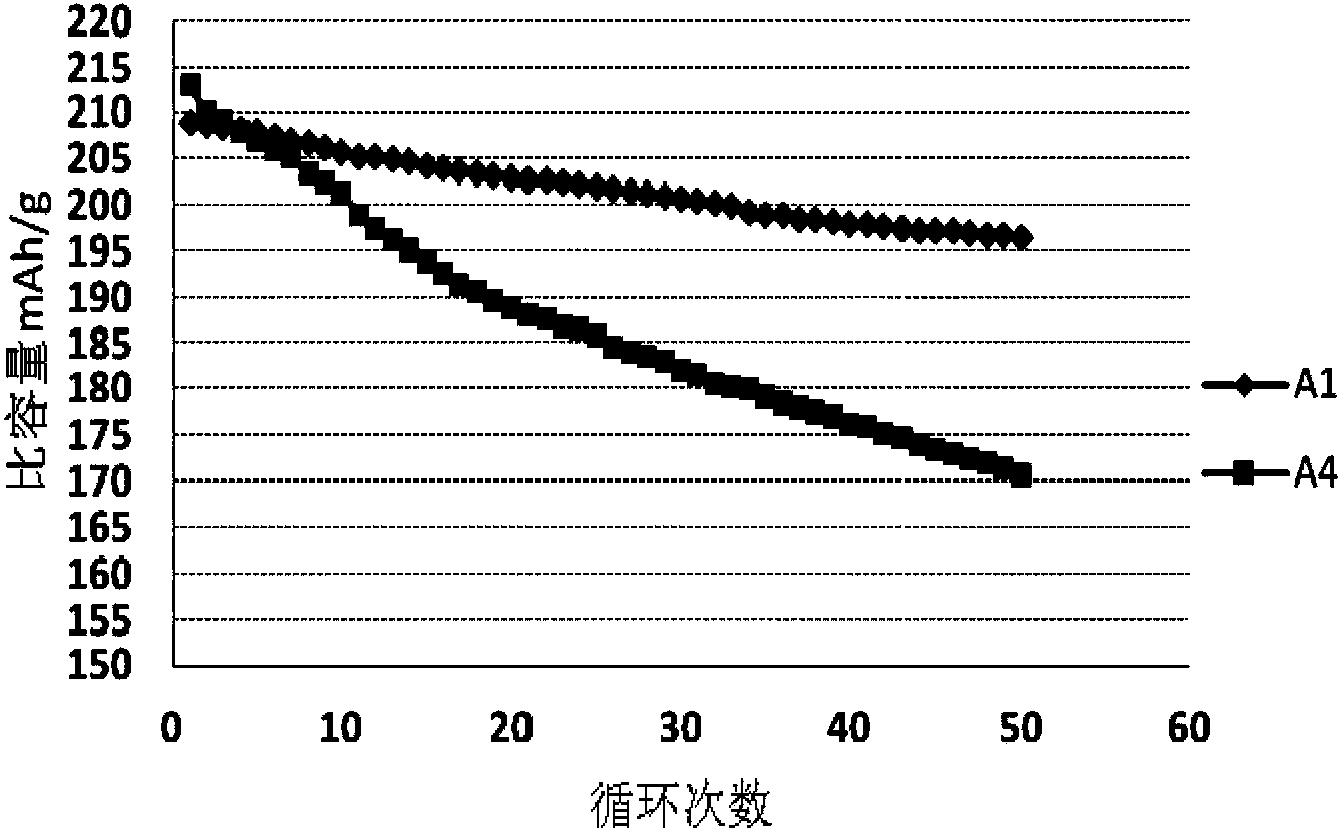

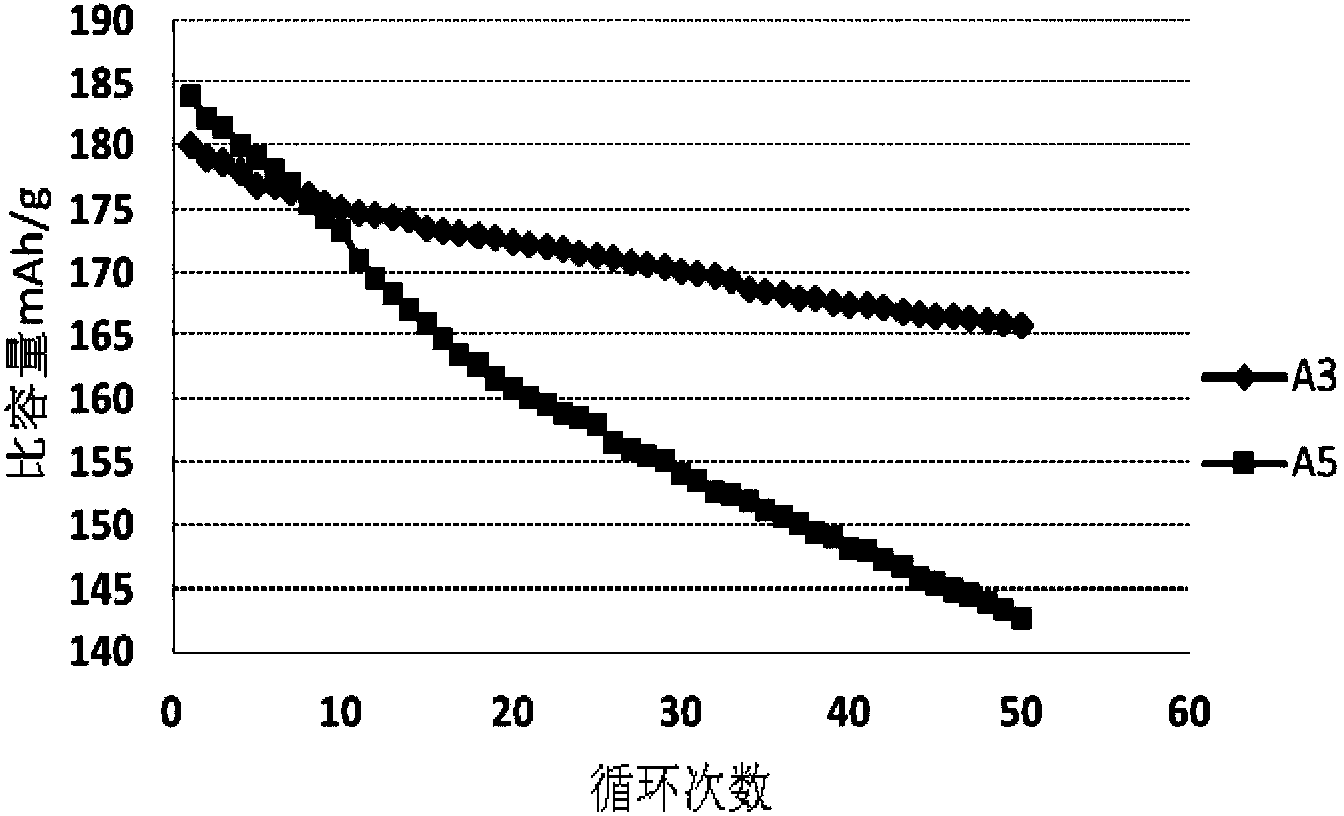

Embodiment 1

[0071] A preparation method for lithium ion battery cathode material, comprising the following steps:

[0072] (1) Weigh lithium hydroxide 8g, lanthanum oxide 18.6g, tantalum oxide 8.5g, nickel cobalt lithium manganate (LiNi 0.5 co 0.2 mn 0.3 o 2 ) 2000g, the four are placed in a 10L stirring tank with 1500g deionized water and stirred evenly to form a precursor slurry;

[0073] (2) Calcining the above precursor slurry obtained, the roasting system is: heating up to 600 °C at 8 °C / min, holding the temperature for 8 hours, cooling with the furnace, and obtaining a fast ion conductor coated with a layer thickness of about 60 nm on the surface layer of lithium nickel cobalt manganese oxide (LiNi 0.5 co 0.2 mn 0.3 o 2 ), the molecular expression of its fast ion conductor is Li 5 La 3 Ta 2 o 12 ;

[0074] (3) Add the nickel cobalt lithium manganese oxide material coated with the fast ion conductor layer to 1.6 L of dilute hydrochloric acid with a concentration of 0.2 mo...

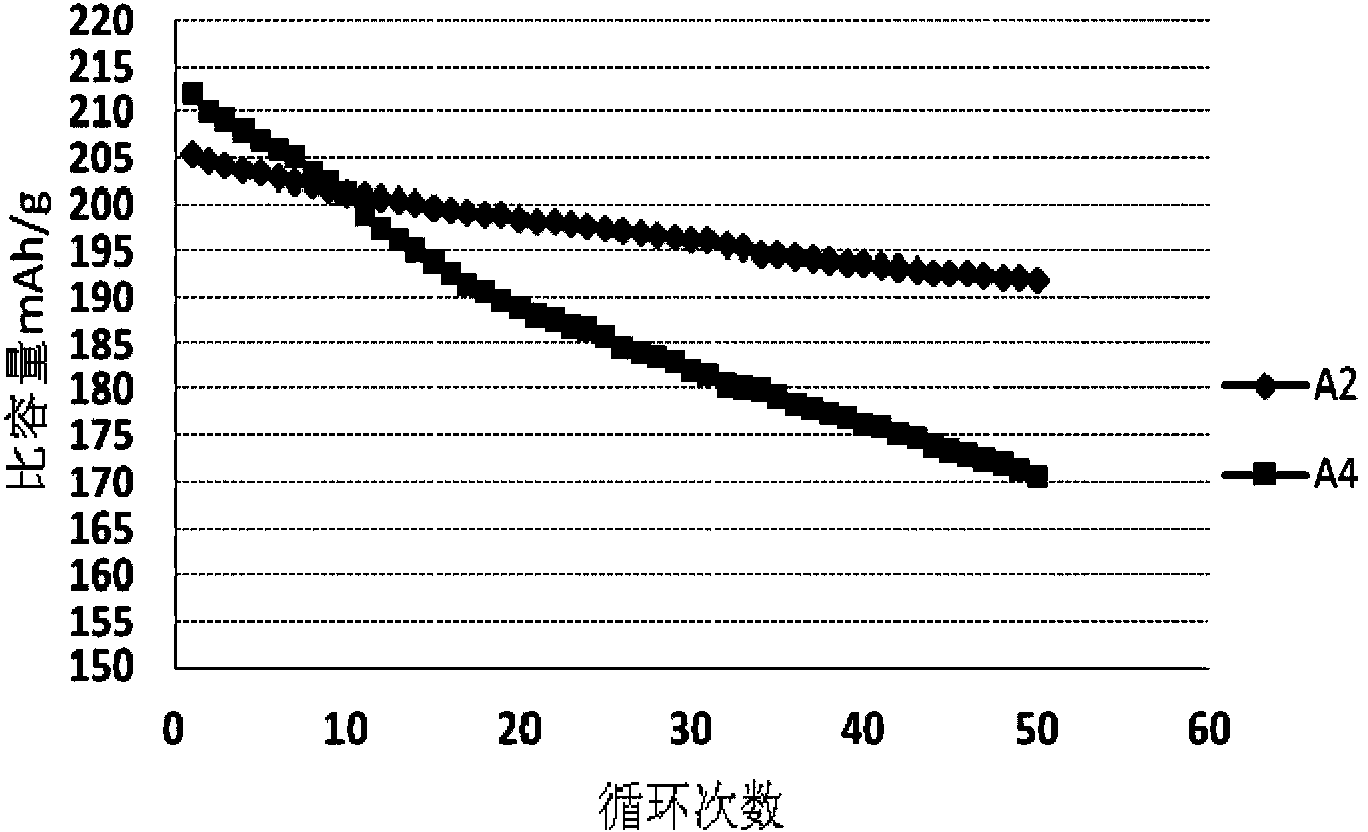

Embodiment 2

[0076] A preparation method for lithium ion battery cathode material, comprising the following steps:

[0077] (1) Weigh 10g of lithium hydroxide, 13g of lanthanum oxide, 8.8g of tantalum oxide, 5.3g of niobium oxide, 8.4g of strontium nitrate, lithium nickel cobalt manganate (LiNi 0.5 co 0.2 mn 0.3 o 2 ) 3000g, the four are placed in a 10L stirring tank with 2000g deionized water and stirred evenly to form a precursor slurry;

[0078] (2) Calcining the above precursor slurry obtained, the roasting system is: heating up to 600 °C at 8 °C / min, holding the temperature for 8 hours, cooling with the furnace, and obtaining a fast ion conductor coated with a layer thickness of about 100 nm on the surface layer of lithium nickel cobalt manganese oxide (LiNi 0.5 co 0.2 mn 0.3 o 2 ), the molecular expression of its fast ion conductor is Li 6 SrLa 2 CaNbO 12 ;

[0079] (3) Add the nickel cobalt lithium manganate material coated with the fast ion conductor layer to 1.8 L of di...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com