Fischer-Tropsch synthesis process based on fixed bed reactor

A fixed bed reactor, Fischer-Tropsch synthesis technology, applied in the petroleum industry, chemical instruments and methods, preparation of liquid hydrocarbon mixtures, etc., can solve the problem of low reactor utilization, unclear fuel injection effect, and large fuel injection power consumption and other problems, to achieve the effect of high product yield, high selectivity, and large operating space velocity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

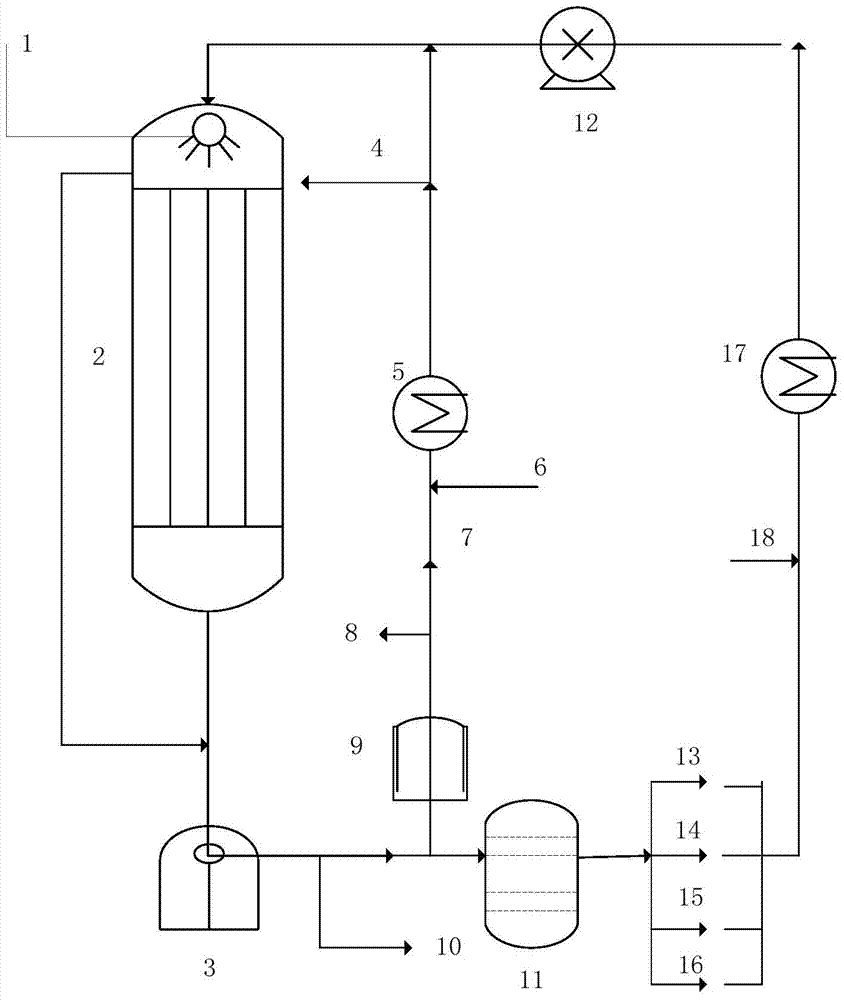

Method used

Image

Examples

Embodiment 1

[0030] Prepare Co-Mn / ZrO according to the method described in patent CN1398669 2 Catalyst, according to final catalyst composition, preparation concentration is 0.8mol / L Co(NO 3 ) 2 ·6H 2 O, ZrOCl 2 and Mn(NO 3 ) 2 1L of the mixed solution, the preparation concentration is 0.2mol / L Na 2 CO 3Solution 1L, under continuous heating and stirring, drop the above two solutions into the beaker for precipitation at the same time, the precipitation temperature is 70°C, the precipitation pH value is 7.0, after the precipitation is completed, it is aged at 80°C for 2h, and washed repeatedly until there is no Cl ion. The filter cake was dried at 110°C for 12h, then calcined in a muffle furnace at 450°C for 2h to prepare the catalyst, and pressed into tablets. The atomic ratio of the catalyst is Co:Mn:Zr=20:0.5:79.5.

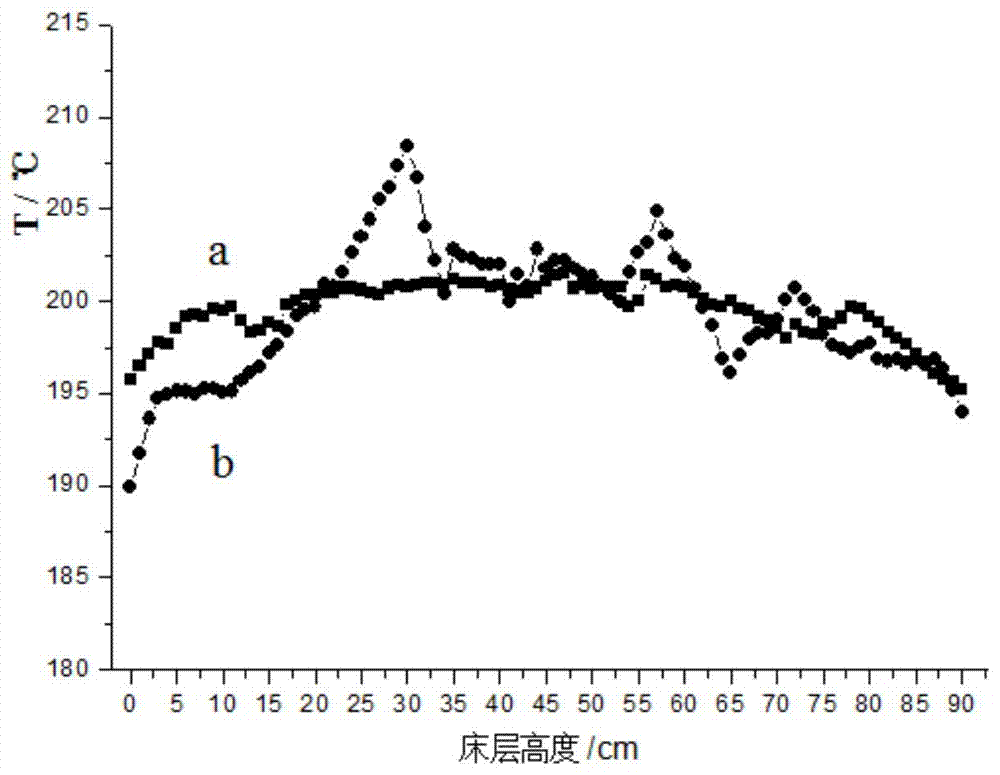

[0031] Take 100ml of the catalyst of 20-40 mesh and install it in a fixed bed reactor with an inner diameter of 14mm and a bed height of about 900mm. The upper 1 / 3 s...

Embodiment 2

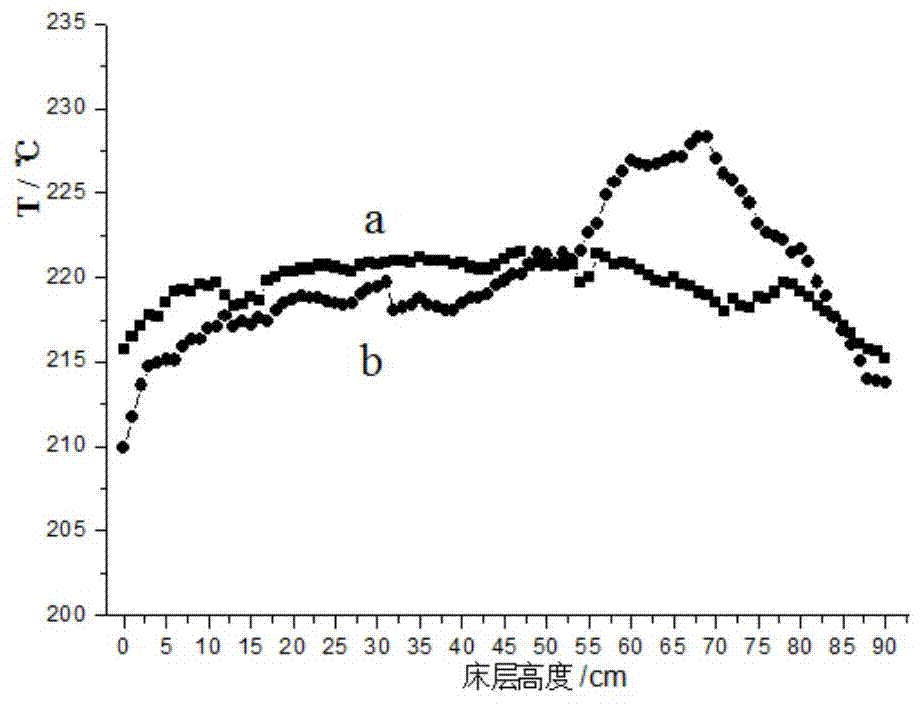

[0035] Prepare Co-Ru / Al according to the method described in patent CN102962066A 2 o 3 Catalyst: Prepare a certain amount of 1mol / L aluminum sulfate aqueous solution, drop 10ml of NaOH, keep the temperature of the water bath at 40°C, keep the time for 180min, and weigh RuCl according to the ruthenium oxide accounting for 0.1(wt)% of the final catalyst 3 ·3H 2 O was added to the solution, peptizer H was added 2 SO 4 , stirred and refluxed at a microwave power of 50W until a transparent sol was maintained for 6h, and then aged at room temperature for 24h to obtain a gel. After drying at 50°C for 2 hours, place it in a microwave oven, heat up to 550°C for 12 hours at 2°C / min, and bake for 12 hours to prepare a catalyst carrier. Weigh Co(NO 3 ) 2 ·6H 2 O, an equal volume is impregnated on the above-mentioned carrier, dried at 120°C for 24h, and finally calcined at 450°C for 10h to prepare the catalyst and pressed into tablets. The atomic ratio of the catalyst is Co:Ru:Al=2...

Embodiment 3

[0040] Prepare the catalyst according to the method described in patent CN101269336: use polystyrene spheres as templates, add 18ml of styrene, 2ml of methacrylic acid and 0.2g of potassium persulfate into the container, then add 160ml of deionized water, and heat at 80°C for 24h. Cool to room temperature, centrifuge, wash to obtain gelatinous polystyrene balls, and dry at 60°C for 24h. According to the composition of the catalyst, add a certain amount of methyl orthosilicate into the hydrochloric acid solution and stir for 15 minutes. During this process, the temperature first rises from room temperature to 60°C and then drops to 30°C. Then pour the solution into the solution containing surfactant Stir in the solution of P123 and butanol for 5 min. The molar composition of each substance in the solution is P123:H 2 O:BuOH:HCl:TMOS=0.005:6.47:0.335:0.01625:1. Finally, polystyrene balls were added to the silica sol (polystyrene balls / polystyrene balls+solution=15(wt)%), and s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com