Method for preparing mineral fertilizer by using serpentine

A technology of mineral fertilizer and serpentine, which is applied in the field of agricultural science, can solve the problems of lack of various trace elements and effective supplementation of mineral nutrients, and achieve the effect of reducing energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

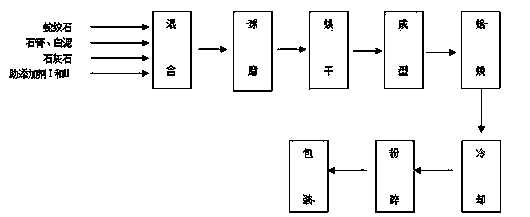

Embodiment 1

[0031] A fertilizer company adopts this process to produce mineral fertilizers, which are added to nitrogen, phosphorus, and potassium ternary compound fertilizers as fillers, which can make the original nitrogen-phosphorus-potassium compound fertilizer more comprehensive and more nutritious. tends to balance. The mineral raw materials used are: 55% serpentine, 14% gypsum, 25% limestone, 12% limestone, 4% auxiliary additive I / II, and auxiliary additive I is potassium feldspar + muscovite (mass ratio 1:1); auxiliary additive II is Glauber's salt + salt (mass ratio 1:1), and the mass ratio between auxiliary additives I and II is 0.75:1. The technological process is as follows: fully mix the above mineral raw materials, and perform ball milling until the particle size is below 0.074mm; then dry the mixed material until the moisture content is less than 5%; the dried powder is formed into a particle size of about 2cm pellets, and enter the activation kiln for roasting, the temper...

Embodiment 2

[0033] A fertilizer company in Shanxi adopts this process to produce fertilizer materials: 37% serpentine, 25% gypsum, 24.5% limestone, 10% limestone, 3.5% auxiliary additive I / II, and auxiliary additive I is illite + carbonic acid Potassium (mass ratio 1:1); auxiliary additive II is salt + sodium fluoride (mass ratio 1:1), and the mass ratio between auxiliary additives I and II is 1.25:1. The process flow is as follows: fully mix the above-mentioned mineral raw materials, and perform ball milling until the particle size is below 0.074mm; then dry the mixed material until the moisture content is less than 5.2%; the dried powder is formed into a particle size of about 1.5cm The pellets are put into the activation kiln for calcination, the temperature is controlled at 950°C, and the calcination time is 1.5 hours. After activation and roasting, the pellets are cooled and pulverized, and can be made into mineral compound fertilizer. Among them, through the third-party component i...

Embodiment 3

[0035]A fertilizer company in Guangdong is a large private enterprise that produces soil conditioners. Using this process, the production cost has been reduced by nearly 51%. The mineral raw materials used are: 52% serpentine, 8% gypsum, 20% limestone, 15.5% limestone, and 4.5% auxiliary additives I / II. Additive I is illite + muscovite (mass ratio 1:1); additive II is mirabilite + sodium fluoride (mass ratio 1:1), and the mass ratio between additives I and II is 1:0.75. The process flow is as follows: fully mix the above mineral raw materials, and perform ball milling until the particle size is below 0.074mm; then dry the mixed material until the moisture content is less than 4.7%; the dried powder is molded and processed into a particle size of about 1.5cm The pellets are put into the activation kiln for calcination, the temperature is controlled at 1025°C, and the calcination time is 60 minutes. After activation and roasting, the pellets are cooled and crushed to make miner...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com