Method for preparing and transferring magnetic nanometer array

A magnetic nano and transfer method technology, applied in the direction of nanostructure manufacturing, nanotechnology, nanotechnology, etc., can solve the problems of unformed transfer and bonding process, and achieve the effect of meeting the manufacturing requirements, simple process and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

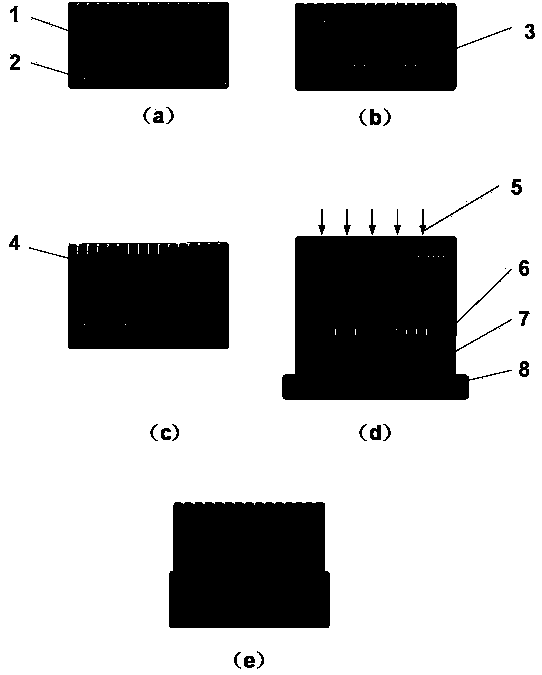

[0009] As shown in the figure, the main steps of the specific embodiment of the present invention include:

[0010] (1) Anneal the aluminum sheet with a purity of 99.999% at 500°C for 30 minutes, then electrochemically polish it in an ethanol solution of perchloric acid until it is bright, place it in a 0.6mol / L sulfuric acid solution, and use a voltage of 20V for one time Oxidation, the oxidation time is 1 hour, then put the aluminum sheet into the mixed solution of phosphoric acid and chromic acid with a mass ratio of 6% and 1.8% respectively, in a water bath at 60°C for 20 minutes, take it out and wash it with distilled water several times, and then repeat it for two times. After secondary oxidation for 2 hours, a non-perforated alumina template 1 with a pore diameter of 50 nm and a depth of 20 μm was obtained as shown in Figure (a).

[0011] (2) Put the deposited sample into the magnetron sputtering table, use FeNi alloy target, and keep the vacuum at 3*10- 5 Pa, forming ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com