Instant chelated solid water-soluble fertilizer

A solid water and chelation technology, applied in fertilization devices, fertilizer mixtures, applications, etc., can solve the problems of not really achieving the integration of water and fertilizer, and achieve the effect of significantly increasing crop income, not easy to agglomerate, and improving soil structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

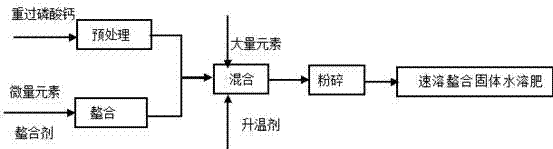

Image

Examples

Embodiment example 1

[0029] Implementation case 1. A kind of instant chelating solid water-soluble fertilizer, its component and proportioning ratio are as follows, all are percentage by weight:

[0030] 25% urea, 15% potassium dihydrogen phosphate, 20% superphosphate, 20% potassium sulfate, 2% magnesium chloride, 1% zinc sulfate, 1% manganese sulfate, 1% sodium molybdate, 1% ferrous sulfate, chelate Mixture 2%, heating agent 10%. The composition and ratio of the chelating agent are: amino acid powder : AMPS-chitosan polymer : AMPS-polyacrylamide copolymer : Polyepoxysuccinate=10:2:2:1. The composition and ratio of the heating agent are: calcium chloride: calcium oxide: sodium acetate = 6:2:2.

[0031] The preparation method is as follows:

[0032] 1) Material pretreatment: Pre-dry the heavy superphosphate in weight percentage, and then add a certain proportion of ammonium bicarbonate to neutralize the free phosphoric acid to obtain the neutralized heavy superphosphate, crush it to make i...

Embodiment example 2

[0035] Implementation case 2. As described in embodiment case 1, its difference is that each raw material component is as follows, is weight percent:

[0036] 30% urea, 10% potassium dihydrogen phosphate, 20% superphosphate, 20% potassium sulfate, 2% magnesium chloride, 1% zinc sulfate, 1% manganese sulfate, 1% sodium molybdate, 1% ferrous sulfate, chelate Mixture 4%, heating agent 8%. The composition and ratio of the chelating agent are: amino acid powder : AMPS-chitosan polymer : AMPS-polyacrylamide copolymer : Polyepoxysuccinate=10:2:2:1. The composition and ratio of the heating agent are: calcium chloride: calcium oxide: sodium acetate = 6:2:2.

Embodiment example 3

[0037] Implementation case 3. As described in embodiment case 1, its difference is that each raw material component is as follows, is weight percent:

[0038] 35% urea, 15% potassium dihydrogen phosphate, 15% calcium superphosphate, 15% potassium sulfate, 2% magnesium chloride, 1% zinc sulfate, 1% manganese sulfate, 1% sodium molybdate, 1% ferrous sulfate, chelate Mixture 6%, heating agent 6%. The composition and ratio of the chelating agent are: amino acid powder : AMPS-chitosan polymer : AMPS-polyacrylamide copolymer : Polyepoxysuccinate=10:2:2:1. The composition and ratio of the heating agent are: calcium chloride: calcium oxide: sodium acetate = 6:2:2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com