Phosphor-doped porous carbon material for super capacitor and preparation method thereof

A technology of porous carbon materials and supercapacitors, applied in the field of materials, can solve the problems of low specific capacitance and high cost, and achieve high specific surface area, low cost and environmental friendliness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

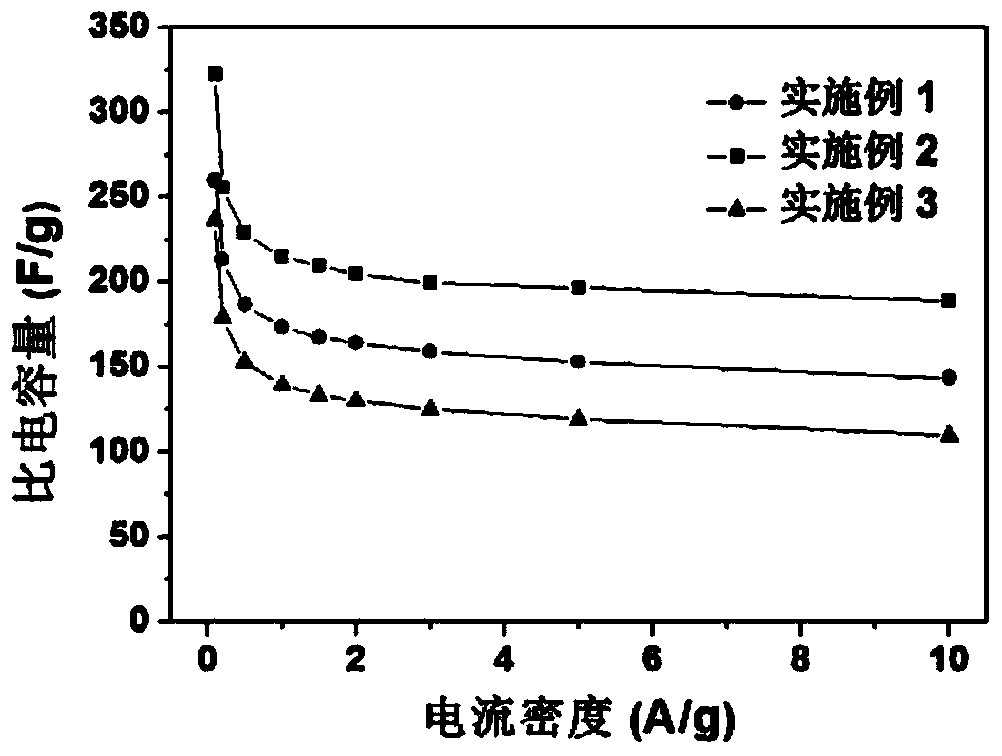

Embodiment 1

[0018] Add 2g of glucose, 1g of phosphoric acid and 0.2g of sulfuric acid into 5g of deionized water respectively, and then stir at 100r / min for 5 hours.

[0019] The homogeneous mixed solution was pre-reacted for 48 hours in a forced air drying oven at a temperature of 100° C. to obtain a solid mixture.

[0020] The pre-reaction product was placed in a high-temperature carbonization furnace, and the temperature was raised to 800°C at a heating rate of 7°C / min under a nitrogen atmosphere, carbonized at a constant temperature for 0.5 hours, and then naturally cooled to room temperature to prepare a phosphorus-doped porous carbon material .

[0021] Thoroughly mix phosphorus-doped porous carbon material (80wt%), conductive carbon black Super-P (10wt%) and polyvinylidene fluoride (10wt%) through mortar grinding, and then add 50 times the mass of polyvinylidene fluoride In the N-methylpyrrolidone, stir well to form a paste. Using a platinum sheet as a current collector, the abov...

Embodiment 2

[0023] Add 2g of glucose, 1g of phosphoric acid and 1g of sulfuric acid into 10g of deionized water respectively, and then stir at 500r / min for 1 hour.

[0024] The homogeneous mixed solution was pre-reacted for 24 hours in a forced air drying oven at a temperature of 150° C. to obtain a solid mixture.

[0025] The pre-reaction product was placed in a high-temperature carbonization furnace, and the temperature was raised to 800°C at a heating rate of 5°C / min under a nitrogen atmosphere, carbonized at a constant temperature for 1 hour, and then naturally cooled to room temperature to obtain a phosphorus-doped porous carbon material .

[0026] Thoroughly mix phosphorus-doped porous carbon material (80wt%), conductive carbon black Super-P (10wt%) and polyvinylidene fluoride (10wt%) through mortar grinding, and then add 50 times the mass of polyvinylidene fluoride In the N-methylpyrrolidone, stir well to form a paste. Using a platinum sheet as a current collector, the above-ment...

Embodiment 3

[0028] Add 2 g of fructose, 0.5 g of phosphoric acid and 1 g of sulfuric acid into 10 g of deionized water respectively, and then stir at 300 r / min for 3 hours.

[0029] The homogeneous mixed solution was pre-reacted for 12 hours in a forced air drying oven at a temperature of 200° C. to obtain a solid mixture.

[0030] The pre-reaction product was placed in a high-temperature carbonization furnace, and the temperature was raised to 800°C at a heating rate of 10°C / min under a nitrogen atmosphere, carbonized at a constant temperature for 2 hours, and then naturally cooled to room temperature to obtain a phosphorus-doped porous carbon material .

[0031] Thoroughly mix phosphorus-doped porous carbon material (80wt%), conductive carbon black Super-P (10wt%) and polyvinylidene fluoride (10wt%) through mortar grinding, and then add 50 times the mass of polyvinylidene fluoride In the N-methylpyrrolidone, stir well to form a paste. Using a platinum sheet as a current collector, the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific capacitance | aaaaa | aaaaa |

| Specific capacitance | aaaaa | aaaaa |

| Specific capacitance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com