A kind of scale inhibitor for seawater desalination

A technology of scale inhibitor and aqueous solution, which is applied in the fields of scale removal and water softening, chemical instruments and methods, water/sludge/sewage treatment, etc. Health and ecological environment threats and other issues, to achieve excellent scale inhibition ability, compounding method and operation is simple and easy, and the product quality is good

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

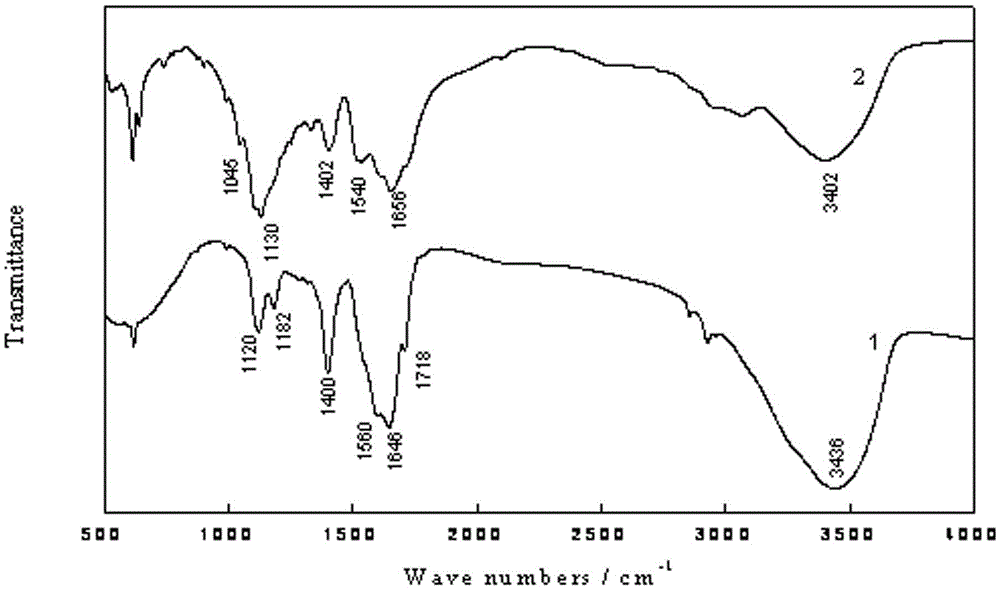

Method used

Image

Examples

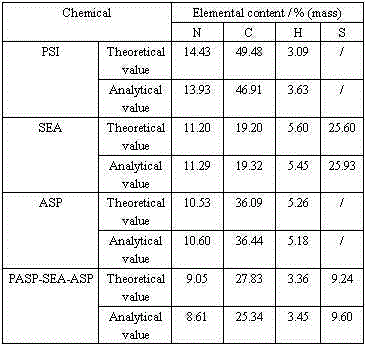

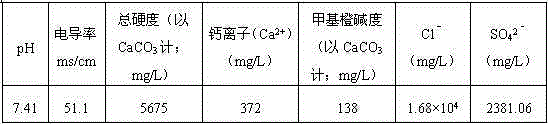

Embodiment 1

[0041] Take 300 grams of aspartic acid and grind it in a mortar, pass it through a 180-mesh sieve, spread it on a medical tray, and then put the tray into an electric blast drying oven for polycondensation reaction, the reaction temperature is 240 ° C, and the reaction is 4 hours. Stir once for 1 hour to obtain 217 grams of yellow-brown polysuccinimide solid; dissolve 11.25 grams of 2-aminoethanesulfonic acid in water and add 15.84 grams of 25% aqueous sodium hydroxide solution dropwise with stirring, and control the reaction temperature to 20-20. 50°C; dissolve 1.33g of aspartic acid in water and add 1.76g of 25% sodium hydroxide aqueous solution dropwise under stirring, and control the reaction temperature at 20-50°C; Add 9.7 grams of polysuccinimide to the flask, then add 30 mL of water to suspend it in water, slowly add 2-aminoethanesulfonate solution and sodium hydrogen aspartate solution dropwise under stirring, and use it every half hour Adjust the pH to 8 with 25% aque...

Embodiment 2

[0046]Take 300 grams of aspartic acid and grind it in a mortar, pass it through a 180-mesh sieve, spread it on a medical tray, and then put the tray into an electric blast drying oven for polycondensation reaction at a reaction temperature of 230°C for 5 hours. Stir once for 1 hour to obtain 217 grams of yellow-brown polysuccinimide solid; dissolve 10 grams of 2-aminoethanesulfonic acid in water and add 15.36 grams of 25% aqueous sodium hydroxide solution dropwise under stirring, and control the reaction temperature to 20-20. 50°C; dissolve 2.66 grams of aspartic acid in water and add 3.84 grams of 25% sodium hydroxide aqueous solution dropwise under stirring, and control the reaction temperature at 20-50°C; Add 9.7 grams of polysuccinimide to the flask, then add 30 mL of water to suspend it in water, slowly add 2-aminoethanesulfonate solution and sodium hydrogen aspartate solution dropwise under stirring, and use it every half hour Adjust the pH to 9 with 25% sodium hydroxide...

Embodiment 3

[0051] Take 300 grams of aspartic acid and grind it in a mortar, pass it through a 180-mesh sieve, spread it on a medical tray, and then put the tray into an electric blast drying oven for polycondensation reaction at a reaction temperature of 250°C for 3.5 hours. Stir once every 1 hour to obtain 217 grams of yellow-brown polysuccinimide solid; dissolve 10 grams of 2-aminoethanesulfonic acid in water and add 16.64 grams of 25% aqueous sodium hydroxide solution dropwise under stirring, and control the reaction temperature to 20 ~50 ℃; Dissolve 2.66 grams of aspartic acid in water and add 4.16 grams of 25% aqueous sodium hydroxide solution dropwise under stirring, and control the reaction temperature to be 20~50 ℃; Add 9.7 grams of polysuccinimide to the flask, then add 30 mL of water to suspend it in water, slowly add 2-aminoethanesulfonate solution and sodium hydrogen aspartate solution dropwise under stirring, every half hour Use 25% sodium hydroxide aqueous solution to adjus...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com