Copper-nickel sulfide ore concentrate smelting method through pyrometallurgy

A technology of sulfide concentrate and pyrometallurgy, which is applied in the direction of rotary drum furnace, crucible furnace, furnace, etc., can solve the problems of limited application in production, reduce slag temperature, interfere with the clarification and separation of slag and matte, and avoid sticking and cooling problems, increased metal recovery, and the effect of shortening the blowing process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

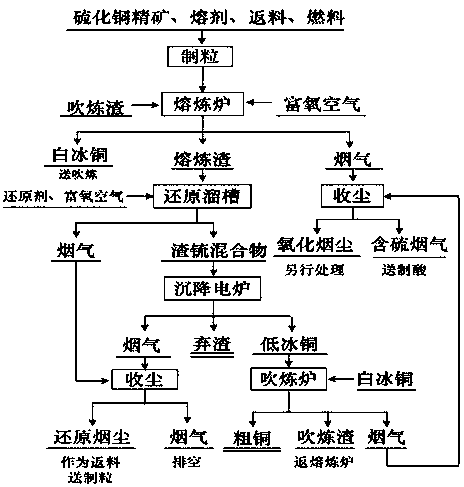

[0039] On the basis of the traditional matte smelting process, the copper concentrate, flux, return material, and blowing slag are mixed in proportion, continuously added to the smelting furnace, and an appropriate amount of coal is added as fuel, and smelted under oxygen-enriched conditions to produce White matte.

[0040] The copper concentrate composition (%) used is:

[0041]

[0042] The composition of anthracite used as fuel is:

[0043]

[0044] According to the iron content of the copper concentrate and the SiO contained in the charge 2 Mass ratio = 1:0.9 to add quartz ingredients. In the smelting process of the top-blown furnace (inner diameter 4 meters, furnace height 13.6 meters), 60 tons of copper concentrate, 1.2 tons of soot (containing Cu8%), 0.3 tons of blowing slag (containing Cu4% , Fe 3 o 4 37%), while adding 2.5 tons of anthracite, 18000N m 3 Oxygen-enriched air with an oxygen concentration of 68% and 7 tons of quartz stone (containing SiO 2 80...

Embodiment 2

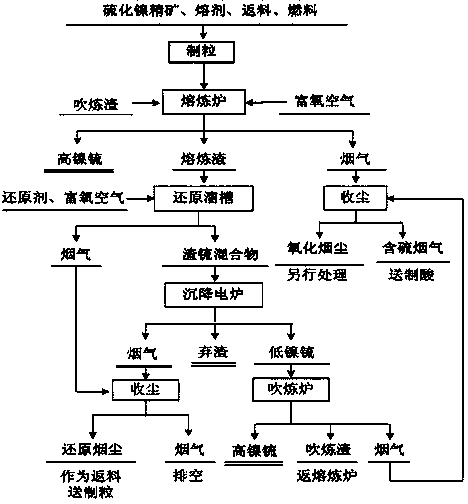

[0053] On the basis of the traditional nickel smelting process, the nickel concentrate, flux, return material, and blowing slag are mixed in proportion, continuously added to the smelting furnace, and an appropriate amount of coal is added as fuel, and smelted under oxygen-enriched conditions. Nickel matte.

[0054] The nickel concentrate composition (%) used is:

[0055] element Ni Cu co Fe S SiO 2 CaO MgO content 6.36 3.69 0.2 31.34 25.36 11.2 2.55 6.94

[0056] The composition of anthracite used as fuel is:

[0057] Element fixed carbon Volatile matter Ash total % 75.00 10.00 15.00 100.00

[0058] According to the iron content of the nickel concentrate and the SiO contained in the charge 2 Mass ratio = 1: 1 to add quartz ingredients. In the smelting process of the horizontal oxygen side-blowing furnace (furnace specification Φ3.7×16.7m), add 35 tons of nickel concentrate, 1.4 tons of soot (containi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com