A high-voltage lithium-ion secondary battery

A secondary battery and lithium-ion technology, applied in secondary batteries, battery electrodes, circuits, etc., can solve the problem of deteriorating the long-term high-temperature storage performance of high-voltage lithium-ion batteries, exacerbating metal ion dissolution, thickness expansion and Improve the high-temperature storage characteristics, increase the capacity retention rate, and reduce the increase in internal resistance to solve problems such as large internal resistance growth

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0051] The preparation method of the high-voltage lithium-ion secondary battery in this embodiment includes a positive electrode preparation step, a negative electrode preparation step, an electrolyte preparation step, a diaphragm preparation step, and a battery assembly step;

[0052] The positive electrode preparation step is: mix 4.35V high-voltage positive electrode active material lithium cobaltate, conductive carbon black and binder polyvinylidene fluoride at a mass ratio of 95:3:2, and disperse them in N-methyl-2- Pyrrolidone, to obtain the positive electrode slurry, the positive electrode slurry is evenly coated on both sides of the aluminum foil, after drying, calendering and vacuum drying, and after the aluminum lead wire is welded with an ultrasonic welder, the positive electrode plate is obtained. The thickness of the electrode plate is Between 120-150μm;

[0053] The preparation steps of the negative electrode are: mixing graphite, conductive carbon black, binder ...

Embodiment 2

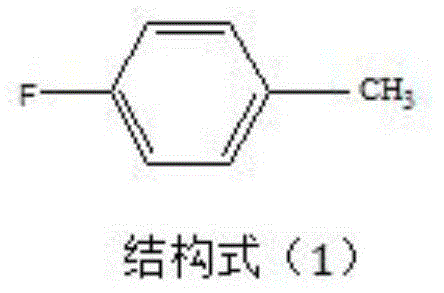

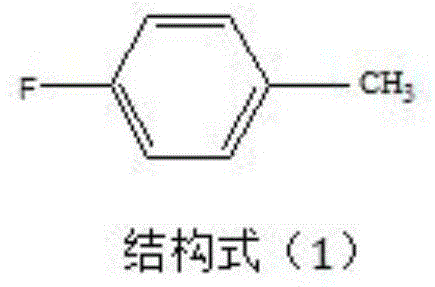

[0071] The preparation method of the electrolyte solution and the preparation method of the lithium ion battery are the same as in Example 1, except that the content of 4-fluorotoluene in the electrolyte solution is reduced from 0.1% to 0.01%. The normal temperature cycle, 45°C cycle and high temperature storage data obtained from the test are shown in Table 1.

Embodiment 3

[0073] The preparation method of the electrolyte solution and the preparation method of the lithium ion battery are the same as in Example 1, except that the content of 4-fluorotoluene in the electrolyte solution is increased from 0.1% to 0.5%. The normal temperature cycle, 45°C cycle and high temperature storage data obtained from the test are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com