Preparation method of TiO2 (titanium dioxide) mesoporous monocrystal microsphere and g-C3N4 heterojunction photocatalyst

A photocatalyst, g-c3n4 technology, applied in the field of photocatalytic materials, can solve the problems of difficult to precisely control the composition and structure, unable to make full use of the visible light part, uneven distribution of each phase, etc., to achieve good photocatalytic degradation of pollutants and Photocurrent response performance, high application prospect and practical value, the effect of cheap raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

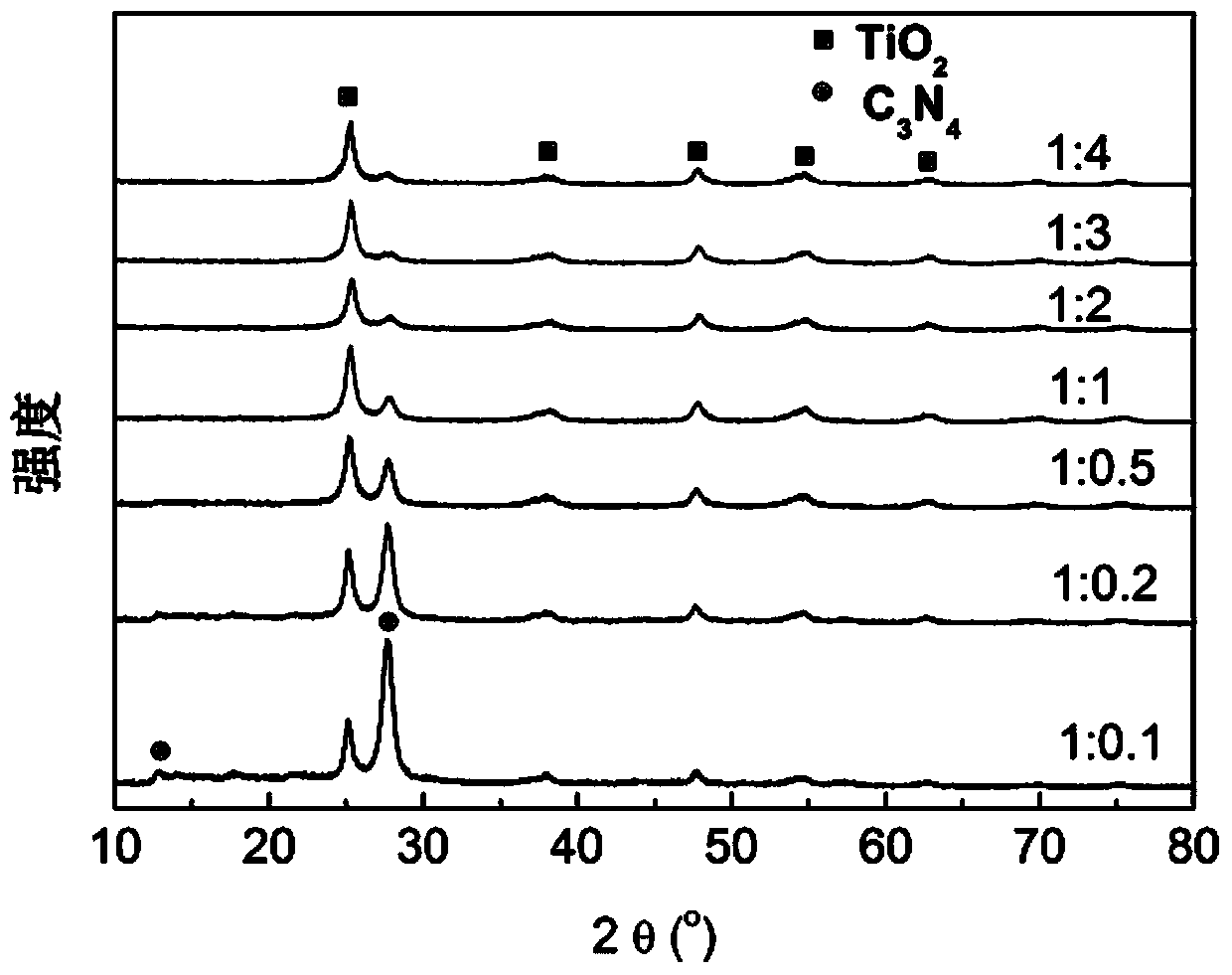

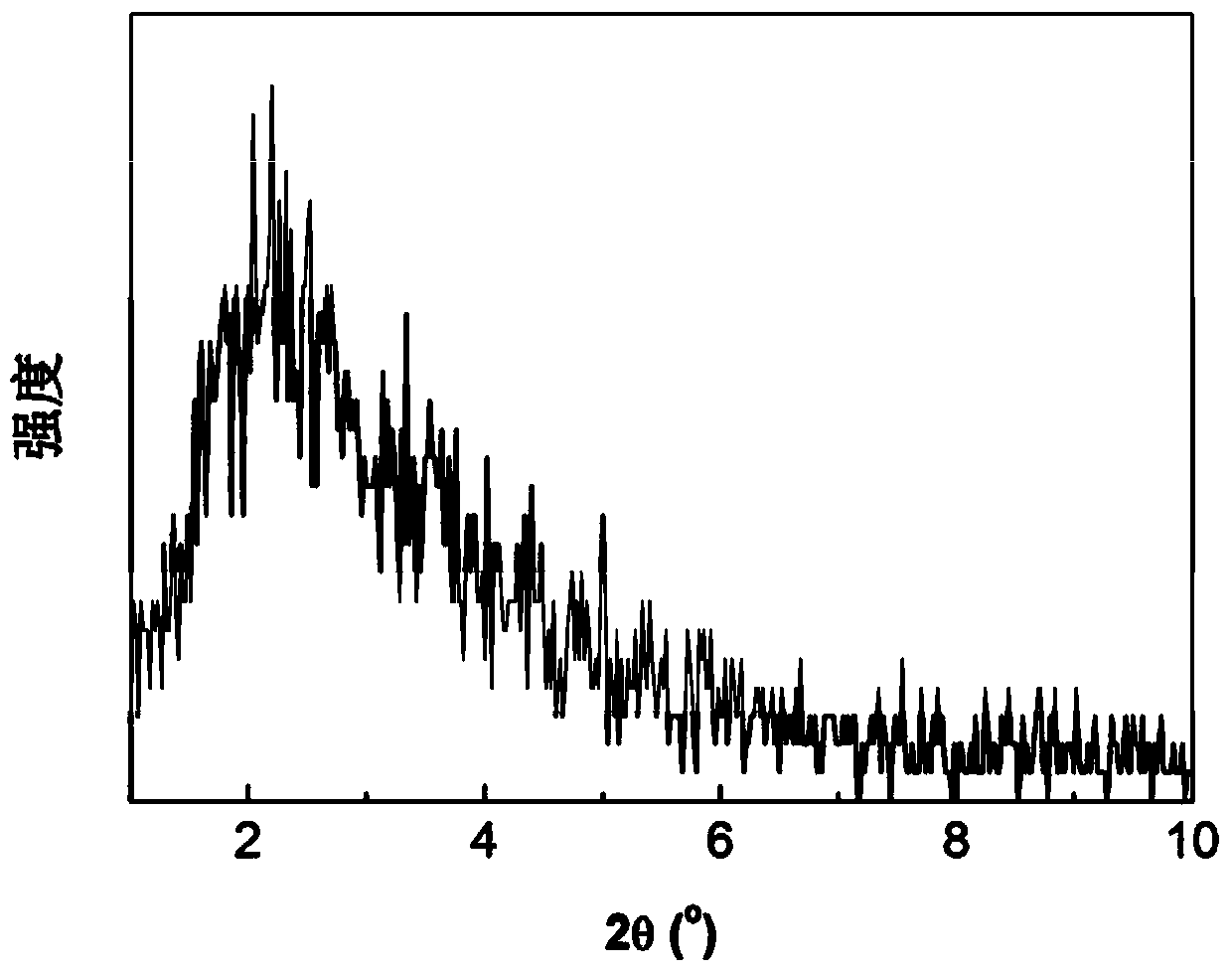

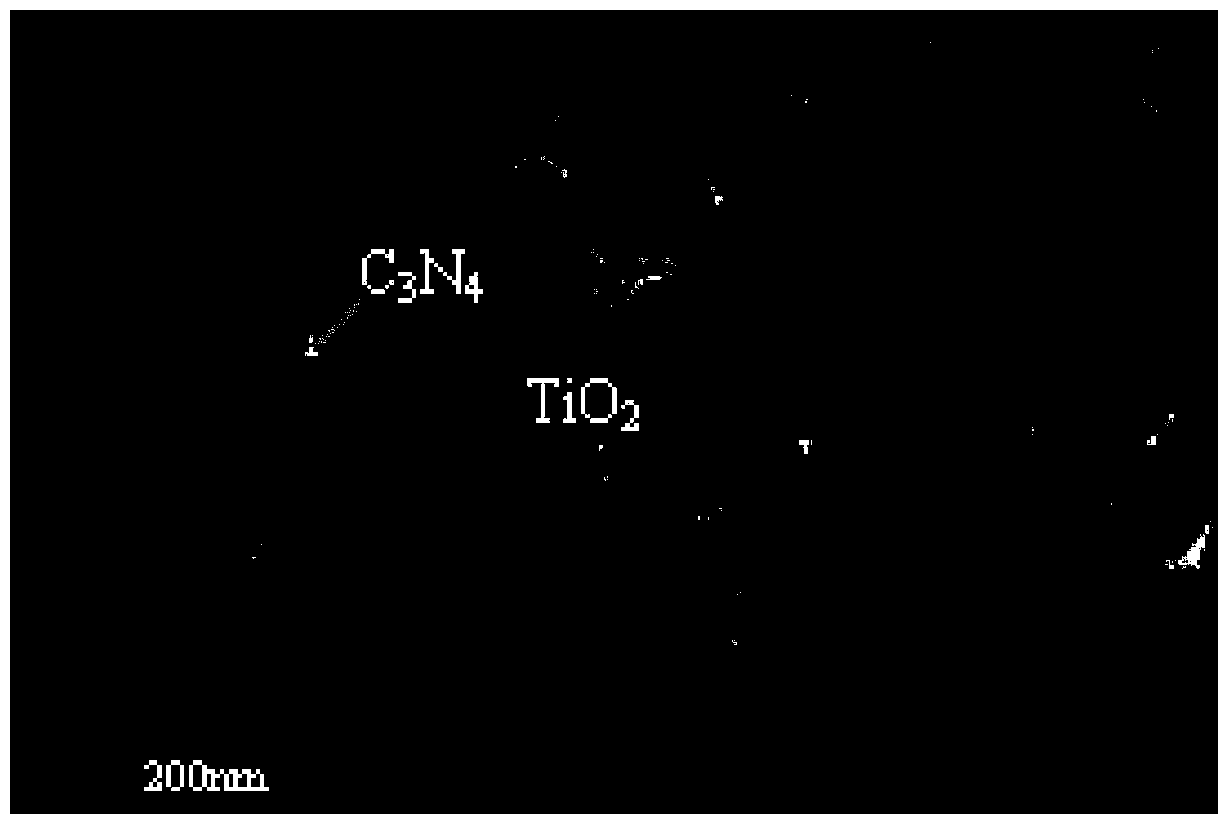

[0025] Take 10g of urea and place it in a crucible, wrap the crucible tightly with aluminum foil, place it in a muffle furnace and calcinate at 550°C in an air atmosphere with a heating rate of 10°C / min, keep it warm for 4 hours and then cool it naturally, the obtained powder is g-C 3 N 4 . Take g-C 3 N 4 Powder 1mmol, placed in 50ml concentration of 5 × 10 -6 mol / L TiCl 4 In the seed solution, keep the temperature in a water bath at 60° C. for 2 hours, and then centrifuge and dry the samples for later use. The above pre-seeded g-C 3 N 4 With 0.1ml sulfuric acid concentration of 0.5mol / L TiOSO 4 solution (TiOSO 4 1mol / L) and 50ml of water were transferred into the autoclave, sealed and placed in a blast drying oven at 100°C for 48 hours. After the reaction, the powder was filtered out, rinsed with deionized water and ethanol, and dried to obtain TiO 2 Mesoporous single crystal microspheres and g-C 3 N 4 The heterojunction photocatalyst is denoted as mpsT-gCN-1. Us...

Embodiment 2

[0027] Take 10g of urea and place it in a crucible, wrap the crucible tightly with aluminum foil, place it in a muffle furnace and calcinate at 550°C in an air atmosphere with a heating rate of 15°C / min, keep it warm for 4 hours and then cool it naturally, the obtained powder is g-C 3 N4 . Take g-C 3 N 4 Powder 1mmol, placed in 100ml concentration of 1 × 10 -5 mol / L seed crystal solution, the temperature was maintained in a water bath at 60°C for 1 h, and then the samples were centrifuged and dried for later use. The above pre-seeded g-C 3 N 4 With 0.5ml sulfuric acid concentration is the TiOSO of 0.4mol / L 4 solution (TiOSO 4 1mol / L) and 50ml of water into the autoclave, sealed and placed in a blast drying oven at 110°C for 36h. After the reaction, the powder was filtered out, rinsed with deionized water and ethanol, and dried to obtain TiO 2 Mesoporous single crystal microspheres and g-C 3 N 4 The heterojunction photocatalyst is denoted as mpsT-gCN-2. Using methyle...

Embodiment 3

[0029] Take 10g of urea and place it in a crucible, wrap the crucible tightly with aluminum foil, place it in a muffle furnace and calcinate at 550°C in an air atmosphere with a heating rate of 20°C / min, keep it warm for 4 hours and then cool it naturally, the obtained powder is g-C 3 N 4 . Take g-C 3 N 4 Powder 1mmol, placed in 100ml concentration of 3 × 10 -5 mol / L seed crystal solution, keep the temperature in a water bath at 70°C for 1 h, and then centrifuge and dry the samples for later use. The above pre-seeded g-C 3 N 4 With 1ml sulfuric acid concentration of 0.3mol / L TiOSO 4 solution (TiOSO 4 1mol / L) and 50ml of water into the autoclave, sealed and placed in a blast drying oven at 110°C for 48h. After the reaction, the powder was filtered out, rinsed with deionized water and ethanol, and dried to obtain TiO 2 Mesoporous single crystal microspheres and g-C 3 N 4 The heterojunction photocatalyst is denoted as mpsT-gCN-3. Using methylene blue (MB) as the targe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com