Broadband multi-layer anti-reflection film and preparation method thereof

An anti-reflection and thin-film technology, which is applied in the field of broadband multi-layer anti-reflection films and their preparation, can solve the problems of harsh operating conditions, complex preparation processes, and difficulty in precise adjustment of film thickness and refractive index.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0060] (1) Nanopolymer hollow particles with a cavity volume fraction of 0.15, a particle size of 90nm and a cavity volume fraction of 0.30, and a particle size of 105nm were prepared as the constituent materials of the first film and the second film. The preparation steps are as follows:

[0061] Take 0.6 grams of the amphiphilic macromolecular reversible addition chain scission chain transfer reagent prepared in step (1) 1.1 of Comparative Example 1 and 80 grams of deionized water to prepare an aqueous solution as the water phase, and add 7 grams of methyl methacrylate Esters, 9 grams of p-divinylbenzene, 0.05 grams of azobisisobutyronitrile and 4 grams of paraffin oil phase are mixed evenly, and ultrasonically pulverized by an ultrasonic pulverizer for 5 minutes at an ultrasonic power of 650w to prepare a fine emulsion . Move the miniemulsion into a reactor, react at 70°C for 6 hours, stop the reaction, cool to room temperature, break the emulsion, and filter with suction ...

Embodiment 2

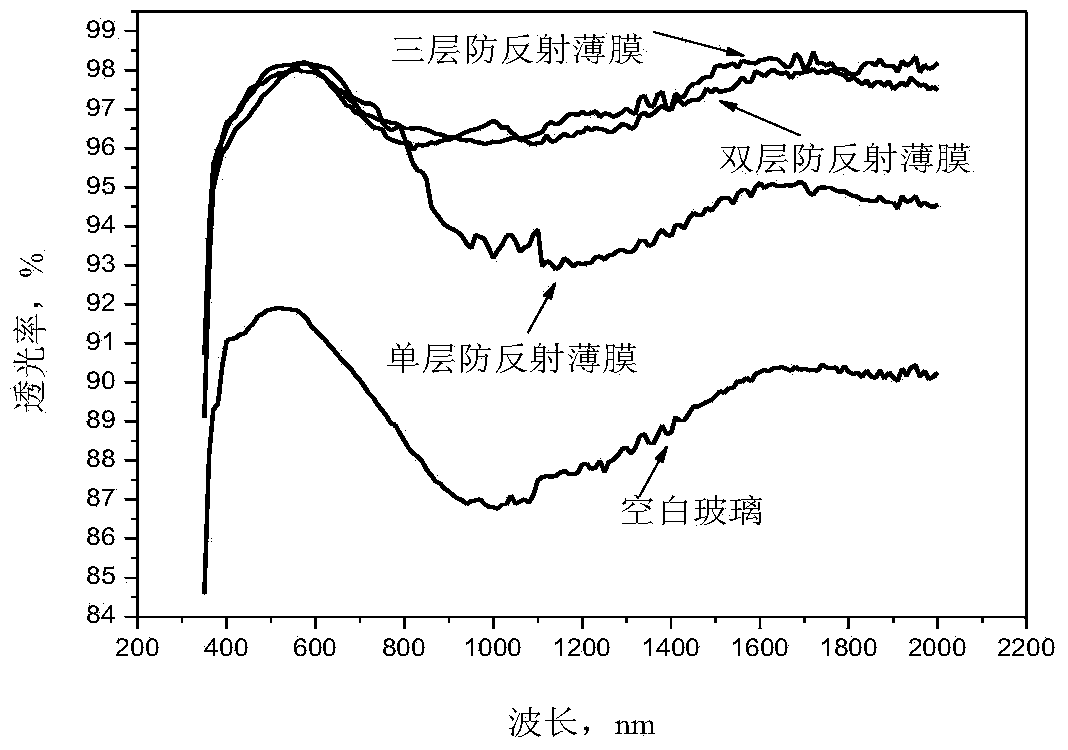

[0072] The operations of Examples 2 and 3 are the same as in Example 1, except that the mass percentage of the aqueous dispersion of nanopolymer hollow particles used in step b) and d) of step (2) of Example 2 The concentration is changed from 1% to 2%, and the mass percent concentration of the aqueous dispersion of nanopolymer hollow particles used in step b) and d) of step (2) of Example 3 is changed from 1% to 3% % to prepare double-layer anti-reflection films. It was found that: with the increase of the concentration of the nanopolymer hollow particle dispersion, the thickness of each layer of the prepared double-layer anti-reflection film remained basically unchanged, which indicated that in the self-assembly process, the dispersion concentration of the nanometer hollow particle had a significant effect on The thickness of the film has little influence, and the thickness of each layer of film mainly depends on the diameter of the nano-polymer hollow particles. When the ma...

Embodiment 4

[0074] (1) The preparation steps of nanopolymer hollow particles are as follows:

[0075] Take 0.5 grams of the amphiphilic macromolecular reversible addition chain scission chain transfer reagent prepared in step (1) 1.1 of Comparative Example 1 and 80 grams of deionized water to prepare an aqueous solution as the water phase, and add 7 grams of methyl methacrylate Esters, 8 grams of p-divinylbenzene, 0.05 grams of azobisisobutyronitrile and 5 grams of paraffin oil phase are mixed evenly, and ultrasonically pulverized by an ultrasonic pulverizer for 5 minutes at an ultrasonic power of 650w to prepare a fine emulsion . Move the miniemulsion into a reactor, react at 80°C for 6 hours, stop the reaction, cool to room temperature, break the emulsion, and filter with suction to obtain highly cross-linked nanopolymer capsules in the shell. The above-mentioned nano polymer capsules are dried in a vacuum oven at 180°C for 5 hours to remove the core material and unreacted residual mon...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com