Instant maca preparation and preparation method thereof

A technology for instant majia and preparations, which is applied in the directions of food preparation, function of food ingredients, food science, etc., can solve the problems of reduced proportion and absorption rate of active ingredients, destruction of functional ingredients, low enzymatic hydrolysis efficiency, etc., and achieves biological preservation. Active, endocrine regulation, suitable for a wide range of people

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

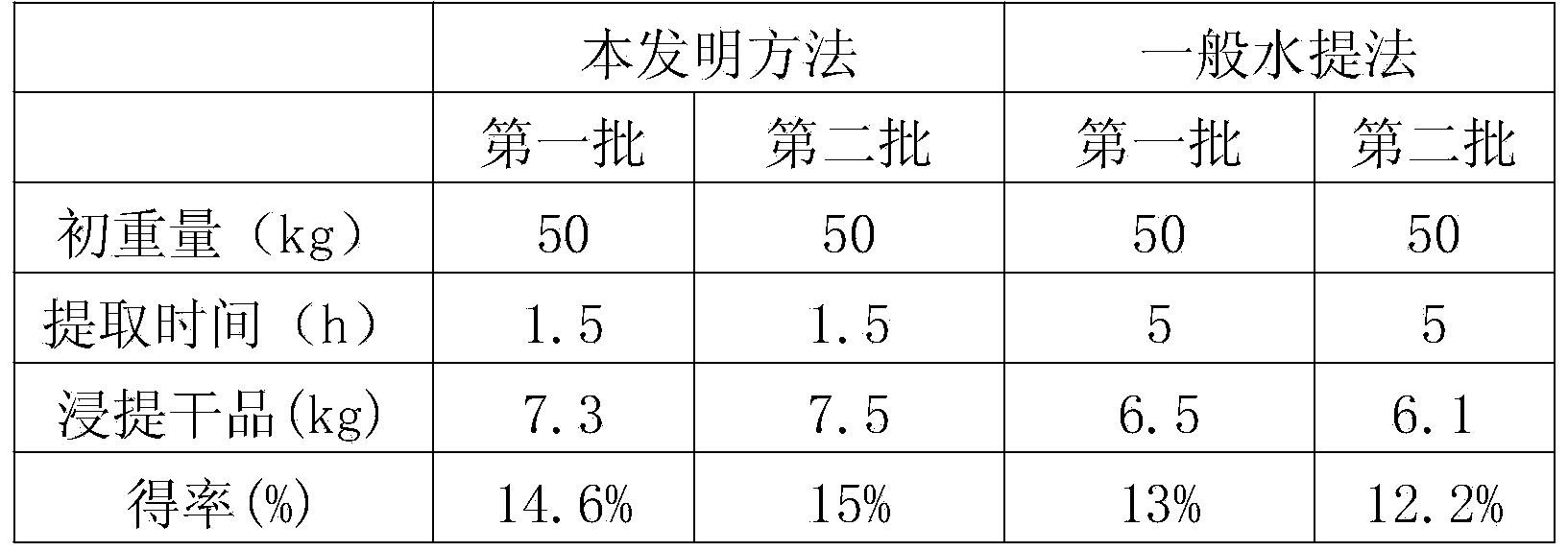

Image

Examples

Embodiment 1

[0043] A kind of instant maga preparation, its key technology is to make according to the following steps:

[0044] 1) Pretreatment: Remove the leaves and roots of fresh maca, clean it, and slice it with a slicer;

[0045] 2) Grinding: pass the flake maca through a grinder to make the particle size of maca uniform, which is beneficial to enzymatic extraction;

[0046] 3) Enzymolysis: Take a compound enzyme preparation with 0.8% of the mass of maca, add pure water with 1 times the mass of maca to the compound enzyme preparation and stir evenly to make the compound enzyme preparation fused. The compound enzyme preparation is composed of amylase, cellulase , hemicellulase and protease, the mass ratio of amylase, cellulase, hemicellulase and protease is 2:3:4:2, and then the composite enzyme preparation after fusion is added to granular maca to make Maca enzymatic hydrolysis; the enzymolysis temperature is controlled at 60°C, the pH is controlled at 4.5, and the enzymolysis time ...

Embodiment 2

[0070] A kind of instant maga preparation, its key technology is to make according to the following steps:

[0071] 1) Pretreatment: Remove the leaves and roots of fresh maca, clean it, and slice it with a slicer;

[0072] 2) Grinding: pass the flake maca through a grinder to make the particle size of maca uniform, which is beneficial to enzymatic extraction;

[0073] 3) Enzymolysis: Take a compound enzyme preparation with 1.5% of the mass of maca, add pure water of 1 times the mass of maca to the compound enzyme preparation and stir evenly to make the compound enzyme preparation fused. The compound enzyme preparation is composed of amylase, cellulase , hemicellulase and protease, the mass ratio of amylase, cellulase, hemicellulase and protease is 2:3:4:2, and then the composite enzyme preparation after fusion is added to granular maca to make Maca enzymatic hydrolysis; the enzymolysis temperature is controlled at 40°C, the pH is controlled at 6, and the enzymolysis time is 1...

Embodiment 3

[0097] A kind of instant maga preparation, its key technology is to make according to the following steps:

[0098] 1) Pretreatment: Remove the leaves and roots of fresh maca, clean it, and slice it with a slicer;

[0099] 2) Grinding: pass the flake maca through a grinder to make the particle size of maca uniform, which is beneficial to enzymatic extraction;

[0100] 3) Enzymolysis: Take a compound enzyme preparation with 1.2% of the mass of maca, add pure water with 1 times the mass of maca to the compound enzyme preparation and stir evenly to make the compound enzyme preparation fused. The compound enzyme preparation is composed of amylase, cellulase , hemicellulase and protease, the mass ratio of amylase, cellulase, hemicellulase and protease is 2:3:4:2, and then the composite enzyme preparation after fusion is added to granular maca to make Maca enzymatic hydrolysis; the enzymolysis temperature is controlled at 50°C, the pH is controlled at 5, and the enzymolysis time is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com