Photochemical preparation method of semiconductor/graphene oxide hollow sphere compound photo-catalyst

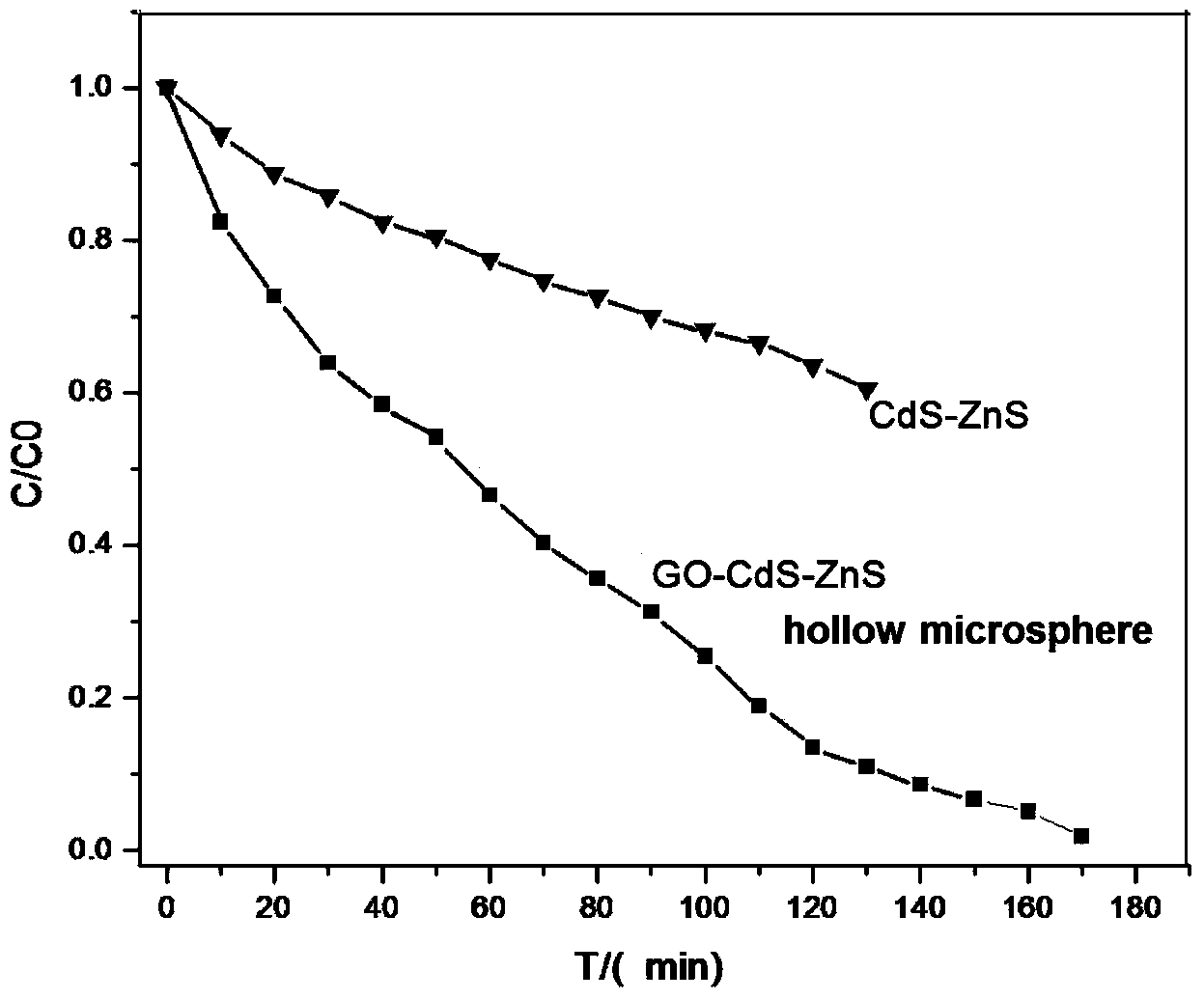

A photocatalyst and semiconductor technology, which is applied in the field of photochemical preparation of semiconductor/graphene oxide hollow sphere composite photocatalyst, can solve problems affecting performance and achieve low cost, large specific surface area, and mild reaction conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

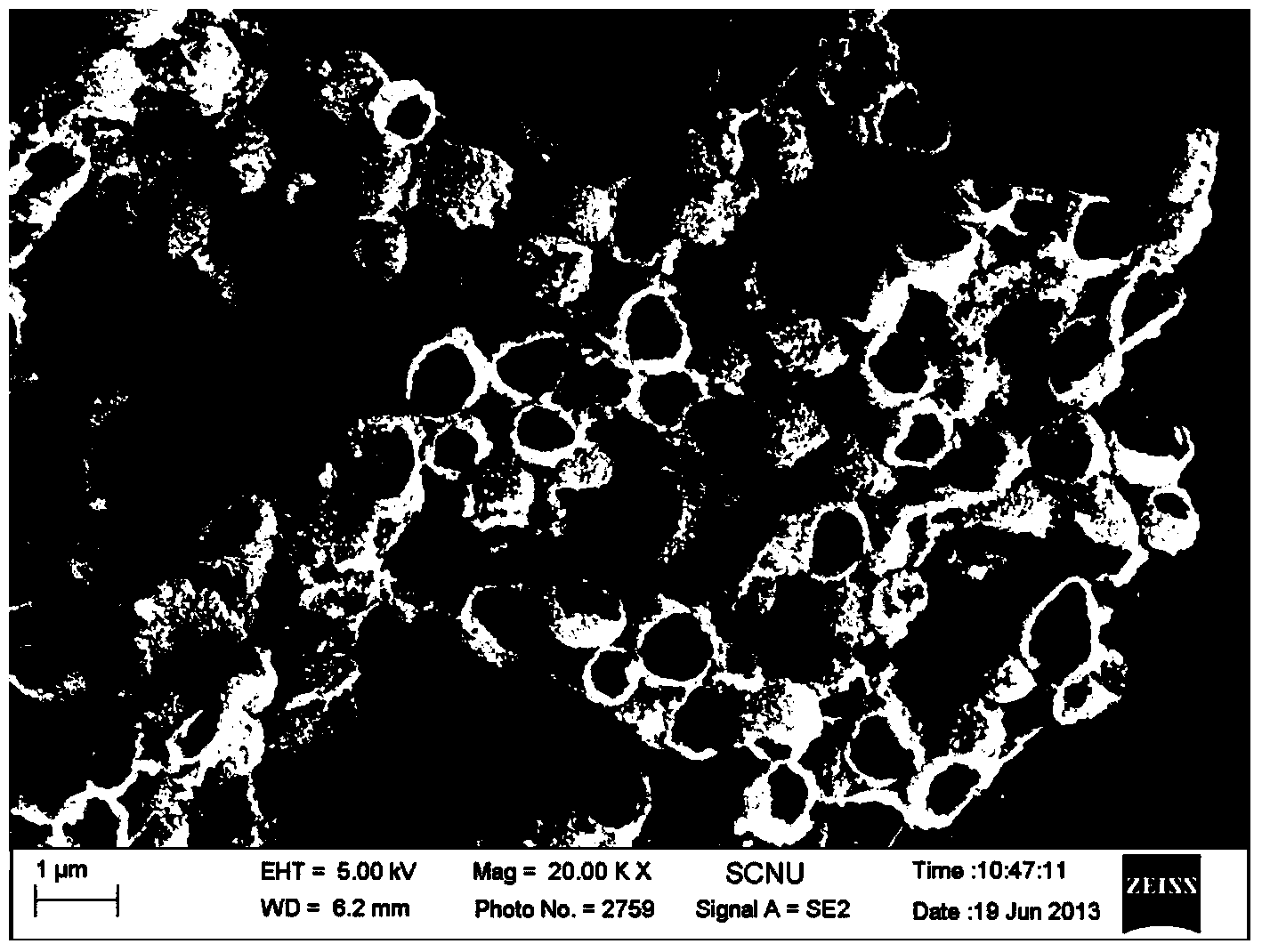

Image

Examples

preparation example Construction

[0027] A photochemical preparation method of semiconductor / graphene oxide hollow sphere composite photocatalyst, comprising the following steps:

[0028] 1) Mix the soluble salt of the semiconductor photocatalyst, sodium thiosulfate, and water evenly to make a precursor solution;

[0029] 2) Add graphite oxide into water and ultrasonically obtain a graphene oxide dispersion;

[0030] 3) adding polymer microspheres to the above graphene oxide dispersion, and fully mixing and dispersing to obtain a mixed dispersion system containing polymer microspheres;

[0031] 4) Add the mixed dispersion system containing polymer microspheres obtained in the previous step to the precursor solution obtained in step 1), and stir to obtain a mixed solution;

[0032] 5) Transfer the mixed solution and place it under the ultraviolet light source for sufficient irradiation to form a precipitate;

[0033] 6) Fully soak the obtained precipitate with an organic solvent to obtain an insoluble solid; ...

Embodiment 1

[0046] A photochemical preparation method of a semiconductor / graphene oxide hollow sphere composite photocatalyst, comprising the steps of:

[0047] 1) Dissolve 2g of cadmium sulfate and 2g of sodium thiosulfate in 50ml of deionized water and stir magnetically for 30 minutes to obtain the precursor solution;

[0048] 2) Add 10 mg of graphite oxide into deionized water, and ultrasonically peel off the graphite oxide for 30 minutes to obtain a graphene oxide dispersion; in the graphene oxide dispersion, the mass percentage of graphene oxide is 0.03%;

[0049] 3) Add polystyrene microspheres to the above-mentioned graphene oxide dispersion and sonicate for 5 minutes to obtain a graphene oxide-coated sphere solution. In the graphene oxide-coated sphere solution, the mass concentration of polystyrene microspheres is 0.5%;

[0050] 4) Add the solution obtained in the previous step to the precursor solution, add water to a total volume of 100ml, and stir magnetically for 30 minutes ...

Embodiment 2

[0055] A photochemical preparation method of a semiconductor / graphene oxide hollow sphere composite photocatalyst, comprising the steps of:

[0056]1) Weigh 2g of copper sulfate and 4g of sodium thiosulfate and dissolve them in 100ml of deionized water, stir magnetically for 30 minutes to obtain the precursor solution;

[0057] 2) Add 8 mg of graphite oxide into deionized water, and ultrasonically peel the graphite oxide for 30 minutes to obtain a graphene oxide dispersion; in the graphene oxide dispersion, the mass percentage of graphene oxide is 0.03%;

[0058] 3) Add the cross-linked styrene / acrylamide copolymer microspheres to the above graphene oxide dispersion and sonicate for 10 minutes to obtain a graphene oxide coated ball solution. In the graphene oxide coated ball solution, cross-linked styrene The mass concentration of ethylene / acrylamide copolymerized microspheres is 0.05%;

[0059] 4) Add the solution obtained in the previous step to the precursor solution, add ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com