A gradient molecular brush polymer with metal cation adsorption capacity and preparation method thereof

A technology of molecular brushes and polymers, applied in chemical instruments and methods, and other chemical processes, can solve the problems of reduced washing efficiency of soaps and detergents, messy and dull hair, dark and stiff clothes, etc., to achieve unique ion adsorption energy, The effect of clear gradient structure and narrow molecular weight distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

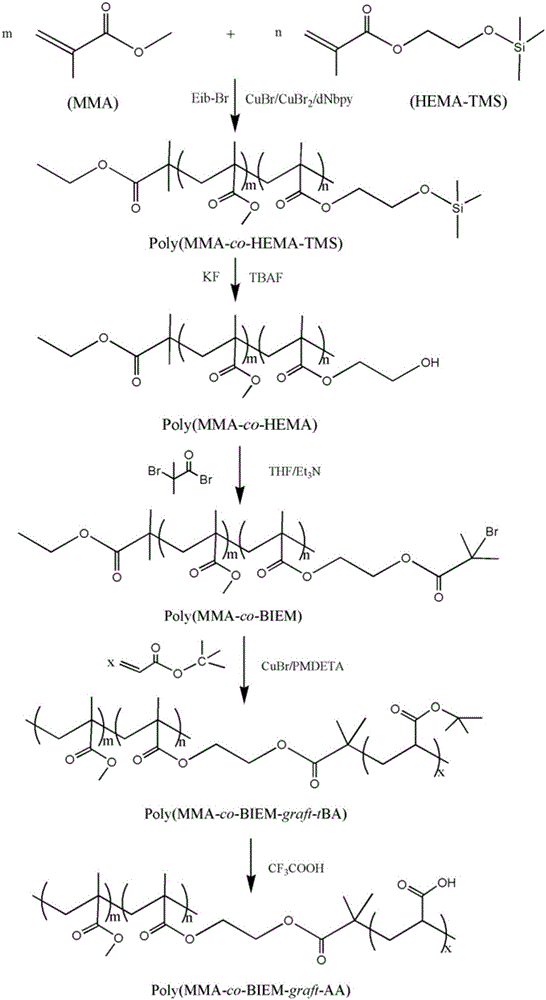

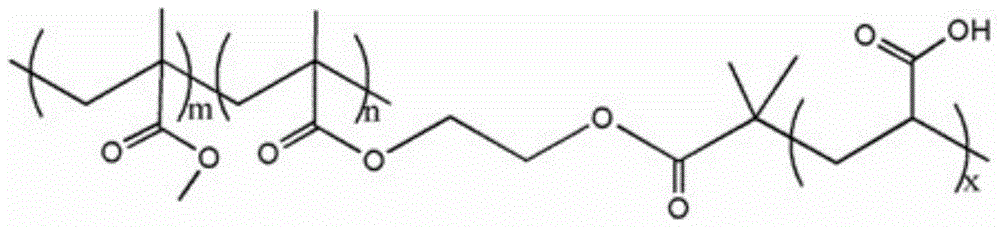

Method used

Image

Examples

preparation example Construction

[0055] (1) Preparation of HEMA-TMS monomer

[0056] In a 500ml dry single-necked round bottom flask, add a stirring bar, organic solvent, hydroxyethyl methacrylate (HEMA), and triethylamine in sequence; place the flask in an ice bath, keep the temperature at 0°C, and drop Trimethylchlorosilane (TMS-Cl) was added dropwise into the flask through a liquid funnel. After the dropwise addition was completed, the reaction was stirred at 0° C. for 2 h, and then reacted at room temperature for 12 h. After the reaction is over, add deionized water to the reaction solution, let stand, separate layers, take the upper layer and wash it repeatedly with deionized water for 3 times, add an appropriate amount of desiccant to dry for 24 hours, filter to remove the desiccant, and distill under reduced pressure to remove the organic solvent. A colorless transparent liquid HEMA-TMS was obtained.

[0057] (2) Preparation of gradient copolymer poly(MMA-co-HEMA-TMS) of MMA and HEMA-TMS

[0058] Ine...

Embodiment 1

[0066] (1) Preparation of HEMA-TMS monomer

[0067] Add magneton, 250ml of anhydrous ether, 10ml of 76mmol of HEMA, 12.7ml of 91mmol of triethylamine into a dry round bottom flask in turn, place the flask in an ice bath, and keep the temperature at 0°C; use a constant pressure dropping funnel Add 11.8ml or 91mmol TMS-Cl dropwise to the flask, and a white precipitate appears in the flask during the dropwise addition; after the dropwise addition, stir and react at 0°C for 2h, and at room temperature for 12h; after the reaction, add deionized water to the reaction solution to dissolve White precipitate of quaternary ammonium salt, let it stand, separate layers, take the upper clear layer and wash it repeatedly with deionized water for 3 times, add an appropriate amount of anhydrous MgSO 4 Dry for 24h, filter to remove MgSO 4 , Diethyl ether was distilled off under reduced pressure at 50°C and 0.06 Torr to obtain a colorless transparent liquid HEMA-TMS.

[0068] (2) Preparation ...

Embodiment 2

[0077] (1) (1) with embodiment 1;

[0078] (2) Compared with Example 1, except that the flask 1 in (2) is exchanged with the substance added in the flask 2, and the dropping rate is changed to 0.8mL / h, other is the same as Example 1;

[0079] (3) (3) with embodiment 1;

[0080] (4) is the same as (4) of embodiment 1.

[0081] The weight-average molecular weight Mw of the gradient molecular brush polymer in this embodiment is 132800, and the molecular weight distribution is 1.32.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| molecular weight distribution | aaaaa | aaaaa |

| molecular weight distribution | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com