High-thermal-conductivity polymer composite and preparation method thereof

A composite material and polymer technology, applied in the field of high thermal conductivity polymer composite material and its preparation, can solve the problems of further improvement of thermal conductivity, loss of mechanical properties, high processing cost, and achieve suitable large-scale production, good mechanical properties, The effect of improving compatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

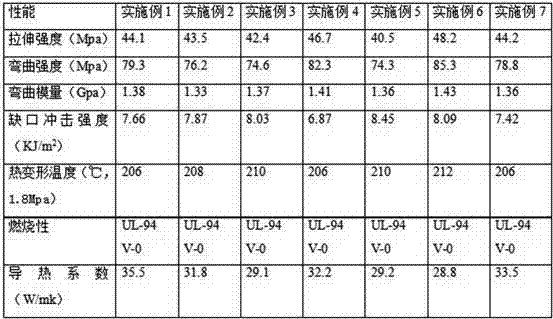

Examples

preparation example Construction

[0026] A method for preparing a high thermal conductivity polymer composite material, comprising the following steps:

[0027] 1) Prepare the coupling agent into 1-3wt% ethanol solution;

[0028] 2) After etching the carbon fiber, soak it with an appropriate amount of coupling agent ethanol solution, and then volatilize to remove the ethanol;

[0029] 3) The polyphenylene sulfide with a formulation amount of 32-78% and the carbon fiber treated in step 2) are melt-extruded and pelletized through a twin-screw extruder to obtain a polyphenylene sulfide / carbon fiber masterbatch;

[0030] 4) Melt, extrude and granulate nylon and glass fiber with a formula amount of 50-72% through a twin-screw extruder to obtain nylon / glass fiber masterbatch;

[0031] 5) Melting and extruding the remaining nylon, remaining polyphenylene sulfide, elastomer and compatibilizer through a twin-screw extruder, and granulating to obtain nylon / polyphenylene sulfide / elastomer masterbatch;

[0032] 6) Mix l...

Embodiment 1

[0039] High thermal conductivity polymer composite material, including the following components: 22 parts of polyphenylene sulfide, 9.5 parts of nylon 66, 1 part of carbon fiber (average aspect ratio of 20, thermal conductivity of 500W / mk), 56 parts of large particle size thermal conductive filler (23 parts of carbonyl iron powder with a particle size of 56 microns, 2.5 parts of copper powder with a particle size of 38 microns, 5 parts of aluminum powder with a particle size of 25 microns, and 25.5 parts of graphite with a particle size of 75 microns), 4 parts of small particle size thermally conductive fillers ( 1.3 parts of multi-walled carbon nanotubes with a particle size of 70 nm, 1.6 parts of graphene with a particle size of 25 nm, 1.1 parts of diamond powder with a particle size of 105 nm), 4 parts of glass fiber, 2 parts of POE, and 1 part of POE-g-MAH , 0.2 parts of coupling agent KH560, 0.12 parts of antioxidant 445 and 0.18 parts of antioxidant 619.

[0040] The pre...

Embodiment 2

[0050] High thermal conductivity polymer composite material, composed of the following components: 10.5 parts of polyphenylene sulfide, 25 parts of nylon 66, 5 parts of carbon fiber (average aspect ratio of 50, thermal conductivity of 600W / mk), 49 parts of large particle size thermal conductive filler Parts (18 parts of carbonyl iron powder with a particle size of 35 microns, 2 parts of copper powder with a particle size of 46 microns, 5 parts of aluminum powder with a particle size of 68 microns, and 24 parts of graphite with a particle size of 77 microns), 5 parts of small particle size thermally conductive fillers (2.3 parts of multi-walled carbon nanotubes with a particle size of 12 nm, 1.6 parts of graphene with a particle size of 88 nm, and 1.1 parts of diamond powder with a particle size of 165 nm), 3 parts of glass fiber, 1 part of POE, and 1 part of POE-g-MAH parts, 0.2 parts of coupling agent KH560, 0.12 parts of antioxidant 445 and 0.18 parts of antioxidant 619.

[...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thermal conductivity | aaaaa | aaaaa |

| Thermal conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com