Method for preparing super high temperature zirconia ceramic fiber

A zirconia ceramic and ultra-high temperature technology, applied in the field of heat preservation and refractory materials, can solve the problems of multi-process, complex and high fiber cost of raw materials, and achieve the effect of simple synthesis process, stable high-temperature performance and single composition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

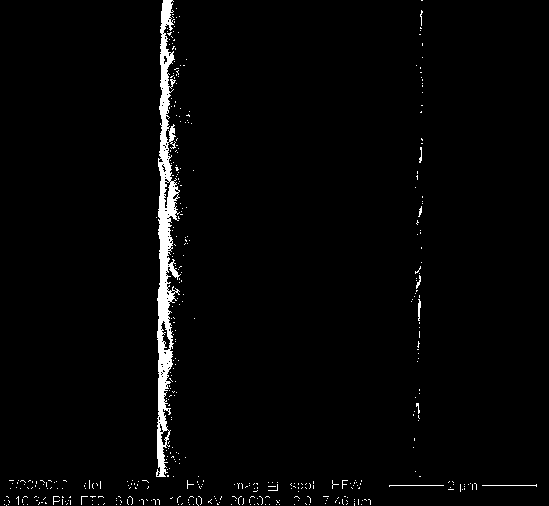

Image

Examples

Embodiment 1

[0029] The preparation method of the fully stable cubic phase zirconia crystal fiber of the present invention adopts the following steps:

[0030] (1) Weighing 40.85g of yttrium nitrate and 100g of zirconium carbonate according to the ratio of yttrium oxide: zirconia molar ratio=10%: 90% and dissolving them in deionized water. 2 times 329.2g; according to the molar ratio of zirconium carbonate: nitric acid = 1:4, measure 183ml of nitric acid (content 65%-68%), and add nitric acid to the mixture of zirconium carbonate and yttrium nitrate at room temperature 30°C under stirring conditions In the solution, continue to stir for 2 hours after the addition to obtain a colorless and transparent reaction solution, which is a composite polymerization solution containing yttrium and zirconium ions.

[0031] (2) The viscosity of the yttrium-zirconium composite sol spinning solution obtained by concentrating under reduced pressure is within the scope of 2~10Pa s;

[0032] (3) Spinning by...

Embodiment 2

[0036] As described in Example 1, the difference is that in the step (1), the consumption of deionized water is changed to 4 times by 2 times of the total mass of yttrium nitrate and zirconium carbonate, that is, changed from 329.2g to 658.4g; zirconium carbonate; The molar ratio of nitric acid is changed from 1:4 to 1:4.5, the amount of nitric acid is changed from 183ml to 206ml, and the concentration of the spinning solution concentrated under reduced pressure in step (2) is changed from 2-10 Pa·s to 10-15Pa·s.

Embodiment 3

[0038] As described in Example 1, the difference is that the consumption of deionized water in step (1) should be 5 times by 2 times of the total mass of yttrium nitrate and zirconium carbonate, that is, change 823g from 329.2g; zirconium carbonate: nitric acid The molar ratio is changed from 1:4 to 1:5, the amount of nitric acid is changed from 183ml to 229ml, and the concentration of the spinning solution concentrated under reduced pressure in step (2) is changed from 2-10 Pa·s to 20-25Pa·s.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com