Process for producing beta-aedelforsite microcrystalline glass by using calcium silicate tailings

A technology of glass-ceramic and calcium silicate, which is applied in the field of producing beta-wollastonite glass-ceramic to achieve the effect of improving product performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0062] Preparation of hydrated sodium aluminosilicate by alkali solution desiliconization of high alumina coal gangue and extraction of alumina from hydrated sodium aluminosilicate

[0063] The chemical composition analysis results of calcium silicate tailings (w B %)as follows:

[0064]

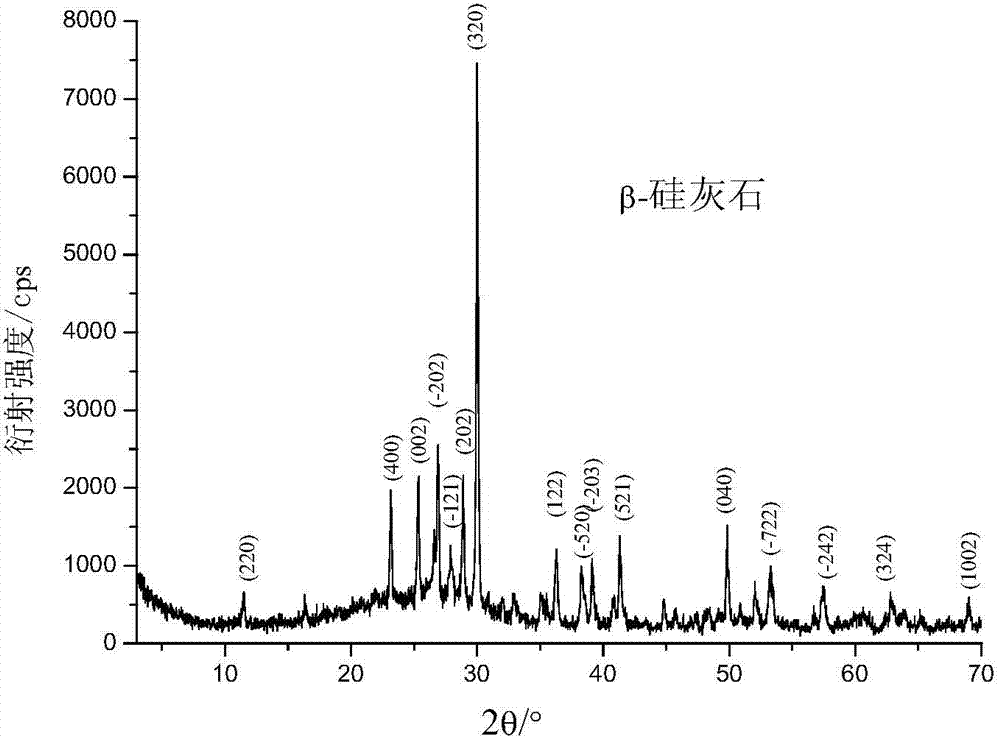

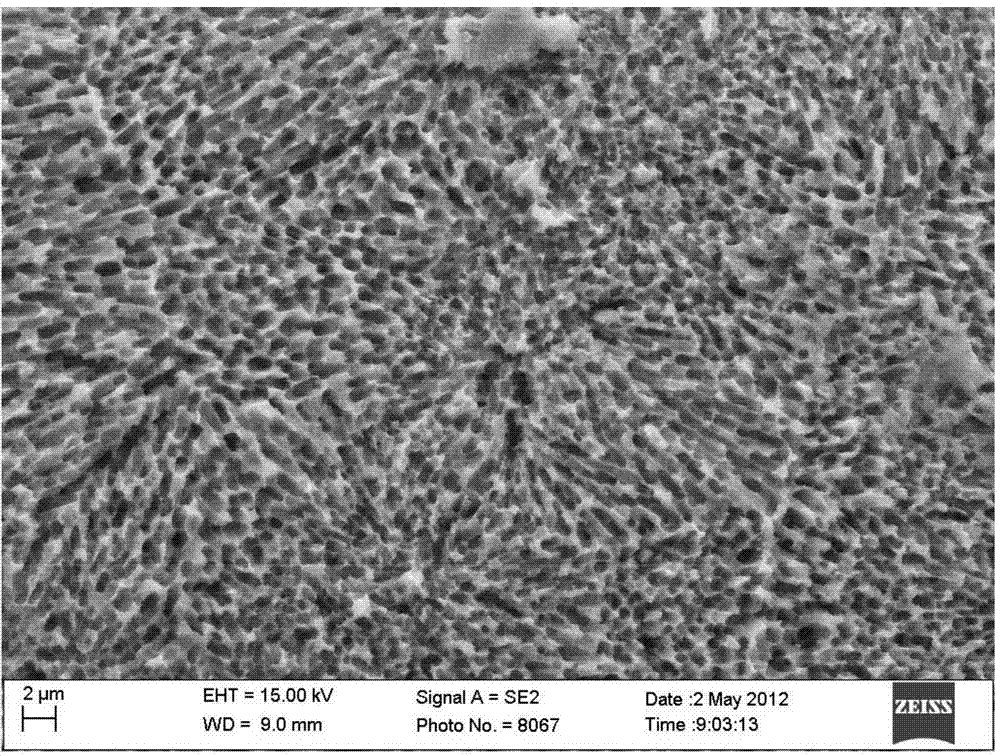

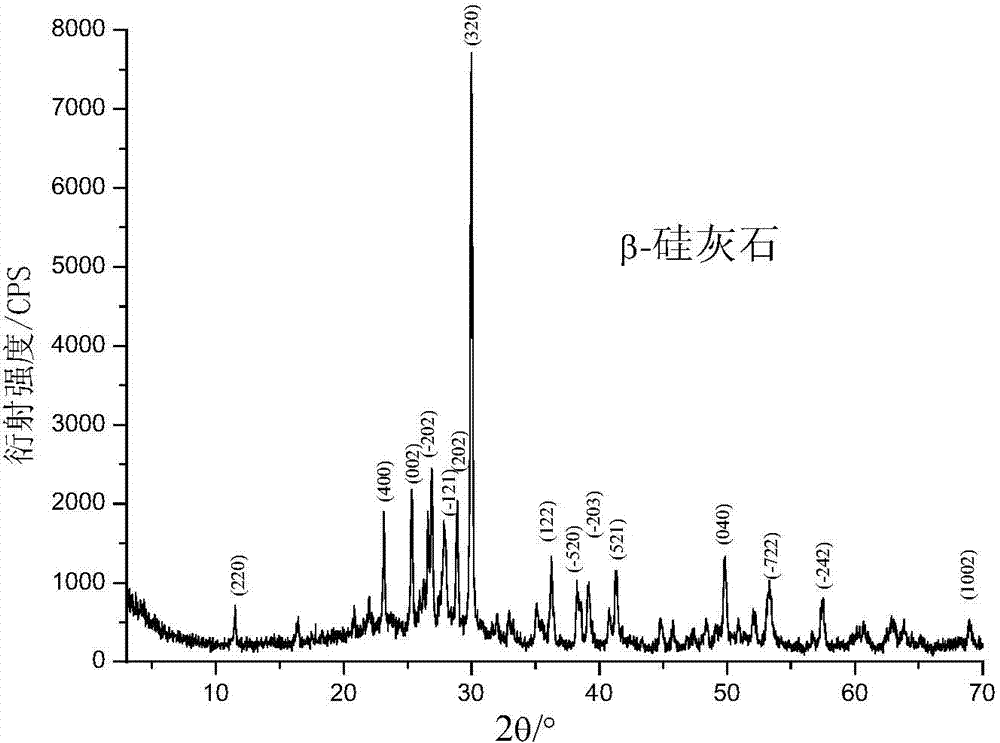

[0065] Accurately weigh 700g of calcium silicate tailings (SC-01), 200g of nepheline syenite, 60g of quartz sand and 50g of borax, and place them in a ball mill for dry grinding for 2 hours to obtain a mixture of -200 mesh > 90% by weight. Powder. Put the mixed powder in a high-temperature furnace and melt it at 1300-1500°C for 2-5 hours to obtain molten glass. Take out the molten glass and pour it into cold water at 20-30°C for 5-20 minutes to prepare basic glass particles. . Dry the basic glass particles at 80-200°C for 1-12 hours, and ball-mill the basic glass particles for 1-3 hours to a basic glass powder with a particle size of 0.1-0.01mm, put it into a steel mold of a certain sh...

Embodiment 2

[0072] Preparation of hydrated sodium aluminosilicate by alkali solution desiliconization of high alumina coal gangue and then extracting silicon after alumina from hydrated sodium aluminosilicate

[0073] The chemical composition analysis results of calcium acid tailings (w B %)

[0074]

[0075] Accurately weigh 500 g of calcium silicate tailings (SC-02), 150 g of nepheline syenite, 45 g of quartz sand, and 30 g of borax, and place them in a ball mill for dry grinding for 2 hours to obtain a mixture of -200 mesh > 90% by weight. Powder. Put the mixed powder in a high-temperature furnace and melt it at 1300-1500°C for 2-5 hours to obtain molten glass. Take out the molten glass and pour it into cold water at 20-30°C for 5-20 minutes to prepare basic glass particles. . Dry the basic glass particles at 80-200°C for 1-12 hours, and ball-mill the basic glass particles for 1-3 hours to a basic glass powder with a particle size of 0.1-0.01mm, put it into a steel mold of a cert...

Embodiment 3

[0082] Pre-desiliconization of potassium-rich rocks to prepare potassium sodium silicate. The filter cake is hydrated sodium aluminosilicate. The hydrated sodium aluminosilicate is modified by soda lime sintering, and the chemical composition analysis of the remaining calcium silicate tailings after alumina is prepared. result (w B %)

[0083]

[0084]Accurately weigh 1000g of calcium silicate tailings (SC-03) and 320g of nepheline syenite, as well as 85g of quartz sand and 63g of borax, and place them in a ball mill for dry grinding for 2 hours to obtain -200 mesh>90% by weight Mix the powder. Put the mixed powder in a high-temperature furnace and melt it at 1300-1500°C for 2-5 hours to obtain molten glass. Take out the molten glass and pour it into cold water at 20-30°C for 5-20 minutes to prepare basic glass particles. . Dry the basic glass particles at 80-200°C for 1-12 hours, and ball-mill the basic glass particles for 1-3 hours to a basic glass powder with a partic...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com