Zinc oxide porous film doped with copper oxide and preparation method thereof

A technology of zinc oxide thin film and porous thin film is applied in the field of copper oxide doped zinc oxide porous thin film and its preparation, which can solve the problems of difference in detection performance, uneven thickness of thin film, small specific surface area of thin film, etc., so as to improve sensitivity and response. The effect of improving speed, specific surface area, and improving gas sensing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] The concrete steps of preparation are:

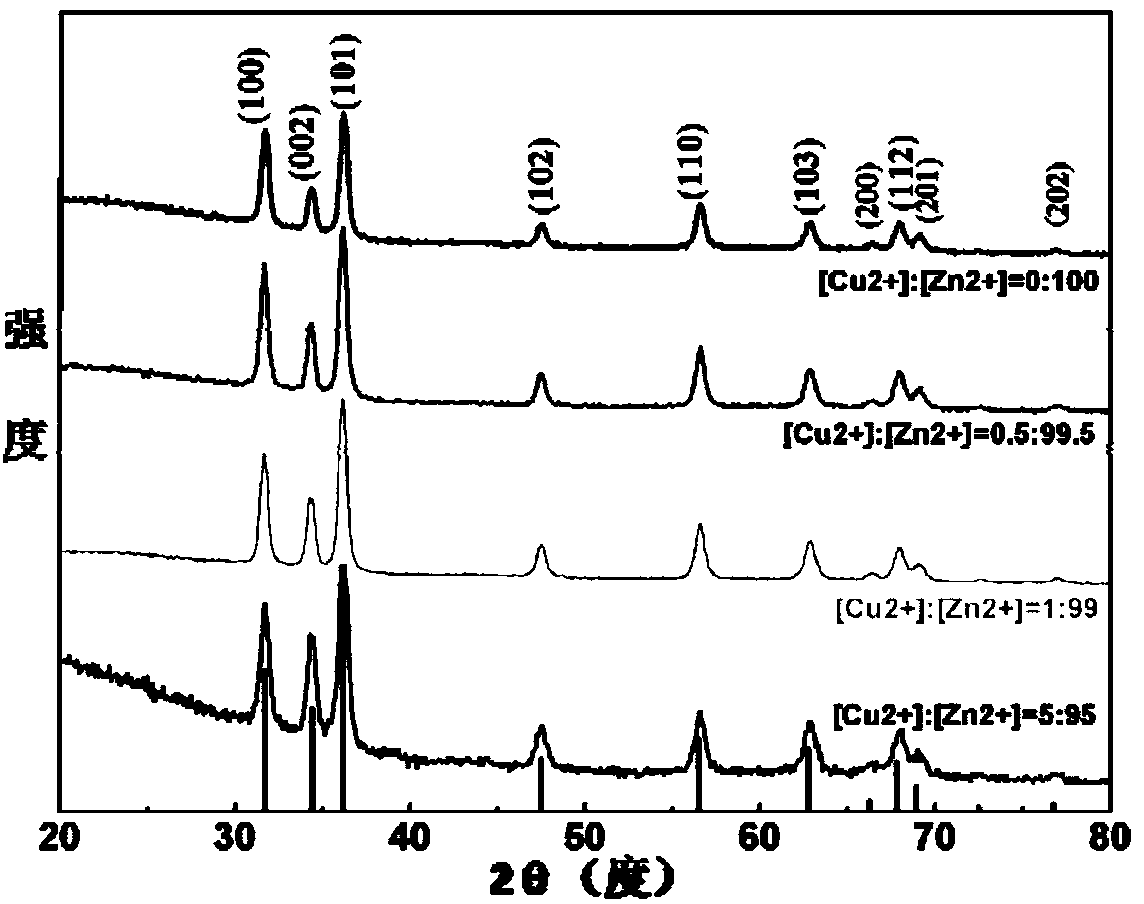

[0040]Step 1, according to the concentration ratio of copper ions: zinc ions is 0.1:99.9, uniformly mix copper nitrate solution and zinc nitrate solution with a concentration of 0.05 mol / L to obtain a metal oxide precursor solution.

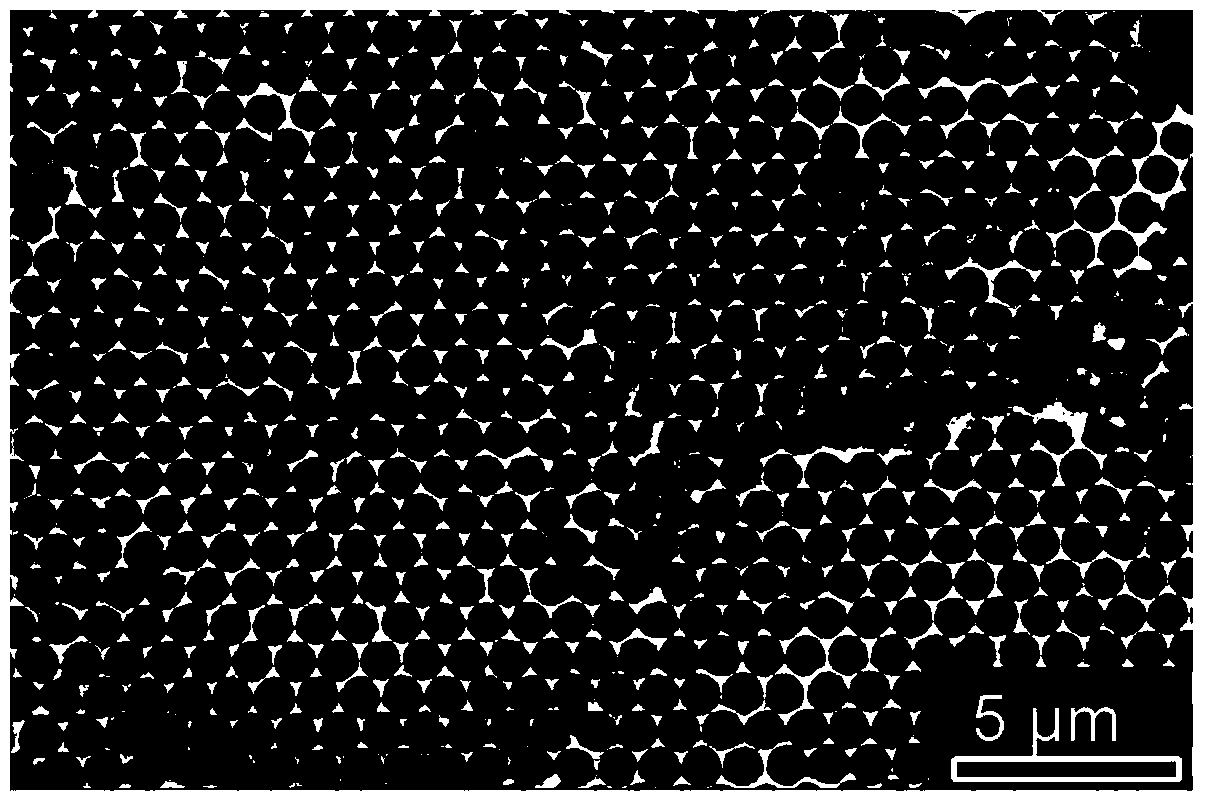

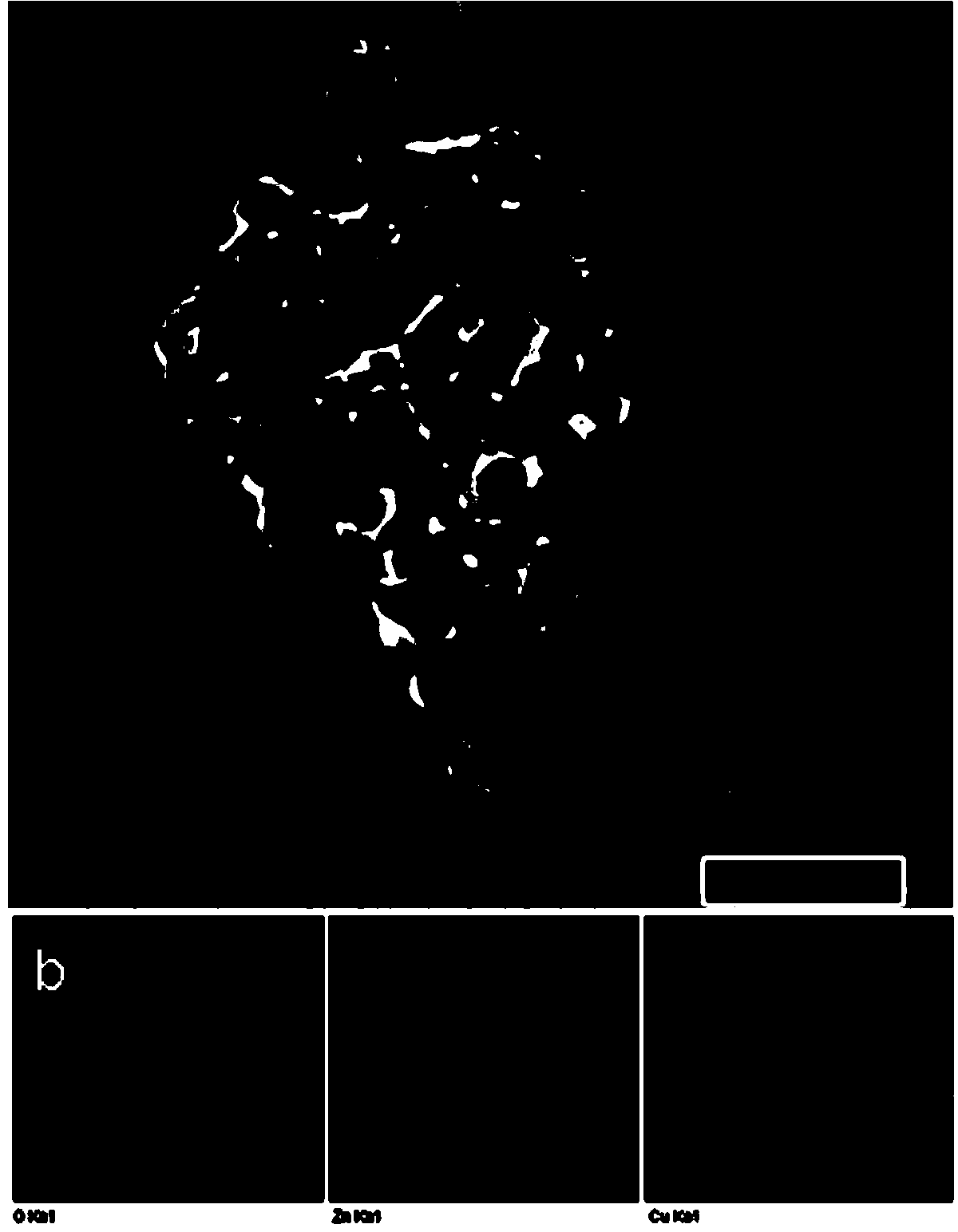

[0041] Step 2, first immerse the single-layer colloidal crystal template in the metal oxide precursor solution, after it is detached from the substrate and floats on the surface of the metal oxide precursor solution, pick up the single-layer colloidal crystal with the substrate and cover it On the surface of the substrate, a substrate covered with a single-layer colloidal crystal and impregnated with a metal oxide precursor solution is obtained; wherein, the colloidal balls used in the single-layer colloidal crystal template are polystyrene colloidal balls, and the substrate has a diameter of 2.5mm , A ceramic tube with a length of 5 mm on which a platinum electrode is attached. Then, the substrate...

Embodiment 2

[0044] The concrete steps of preparation are:

[0045] Step 1, according to the concentration ratio of copper ions: zinc ions is 1:99, uniformly mix copper nitrate solution and zinc nitrate solution with a concentration of 0.1 mol / L to obtain a metal oxide precursor solution.

[0046] Step 2, first immerse the single-layer colloidal crystal template in the metal oxide precursor solution, after it is detached from the substrate and floats on the surface of the metal oxide precursor solution, pick up the single-layer colloidal crystal with the substrate and cover it On the surface of the substrate, a substrate covered with a single-layer colloidal crystal and impregnated with a metal oxide precursor solution is obtained; wherein, the colloidal balls used in the single-layer colloidal crystal template are polystyrene colloidal balls, and the substrate has a diameter of 2.5mm , A ceramic tube with a length of 5 mm on which a platinum electrode is attached. Then, the substrate cov...

Embodiment 3

[0049] The concrete steps of preparation are:

[0050] Step 1, according to the concentration ratio of copper ions: zinc ions is 30:70, uniformly mix copper nitrate solution and zinc nitrate solution with a concentration of 0.25 mol / L to obtain a metal oxide precursor solution.

[0051] Step 2, first immerse the single-layer colloidal crystal template in the metal oxide precursor solution, after it is detached from the substrate and floats on the surface of the metal oxide precursor solution, pick up the single-layer colloidal crystal with the substrate and cover it On the surface of the substrate, a substrate covered with a single-layer colloidal crystal and impregnated with a metal oxide precursor solution is obtained; wherein, the colloidal balls used in the single-layer colloidal crystal template are polystyrene colloidal balls, and the substrate has a diameter of 2.5mm , A ceramic tube with a length of 5 mm on which a platinum electrode is attached. Then, the substrate c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com