Method for separating and purifying peimisine from fritillaria by using high-speed countercurrent chromatography

A high-speed countercurrent chromatography, separation and purification technology, applied in the field of high-speed countercurrent chromatography (HSCCC) to separate and purify fritillary from fritillary, can solve the problems of large consumption of organic reagents, long separation period, low recovery efficiency, etc. Short preparation time, less sample loss, and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] A method for separating and purifying fritillaria from fritillaria by high-speed countercurrent chromatography, comprising the following steps:

[0021] (1) Preparation of crude extract of total alkaloids from Taibai Fritillaria

[0022] Take 100g of Taibai Fritillaria, crush it into a coarse powder, add ammonia water to make sure that the medicinal materials have just been submerged, alkalize for 1 hour, heat reflux with 700mL of 95% ethanol for 4 times, each time for 1.5 hours, combine the extracts from 4 times, and concentrate under reduced pressure Get the extract. Dissolve the extract with 50mL of 0.1M hydrochloric acid, filter the acid solution, extract and degrease the acid solution with petroleum ether, then use 10% sodium hydroxide to adjust the pH to 9~10, and then extract it with dichloromethane four times. The amount of methane was 100mL, 100mL, 80mL, 60mL in turn, the dichloromethane layers were combined, concentrated and dried under reduced pressure to ob...

Embodiment 2

[0031] A method for separating and purifying fritillaria from fritillaria by high-speed countercurrent chromatography, comprising the following steps:

[0032] (1) Preparation of crude extract of total alkaloids from Fritillaria wabu

[0033] Take 100 g of dried and pulverized Fritillaria wabu coarse powder (passed through a 20-mesh sieve), and prepare total alkaloids according to the method in Example 1 to obtain 578 mg of total alkaloid powder.

[0034] (2) High-speed countercurrent chromatographic separation

[0035] The application of high-speed countercurrent chromatography TBE-300B (Shanghai Tongtian Biotechnology Co., Ltd.) separation and purification fritillaria.

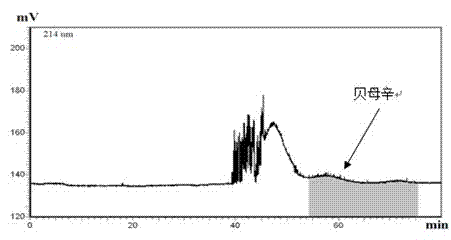

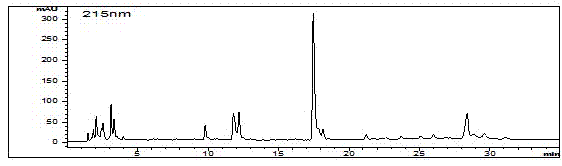

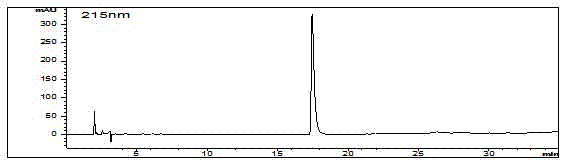

[0036] The two-phase solvent system for high-speed countercurrent chromatography is n-hexane-ethyl acetate-methanol-water (3:5:3:5, v / v / v). Take 50 mg of the total alkaloid powder of fritillaria obtained in step 1 and dissolve it in 6 mL of the same amount of upper phase and lower phase, and inject the sam...

Embodiment 3

[0038] Choose a solvent system with a suitable partition coefficient. It is generally believed that the partition coefficient K value between 0.5 and 2 is better for separation.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com