Preparation method of selenized sulfated chitosan and application of selenized sulfated chitosan to livestock feed

A technology of selenized chitosan sulfate and chitosan sulfate, which is applied to the preparation of water-soluble selenized chitosan sulfate and the application field of livestock and poultry feed, and can solve the problem of complicated preparation, long time and large pollution And other problems, to achieve a wide range of application prospects, simple steps, and improve the effect of growth performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] 1. Add 50ml of dimethylformamide to a three-neck flask with a stirring device, add 10ml of chlorosulfonic acid dropwise in an ice bath, and stir at room temperature for 30min after the dropwise addition to obtain a sulfonated reagent;

[0034] 2. Mix 3.5ml of dichloroacetic acid and 50ml of formamide, add 3g of chitosan and stir for 1 hour to obtain a chitosan solution;

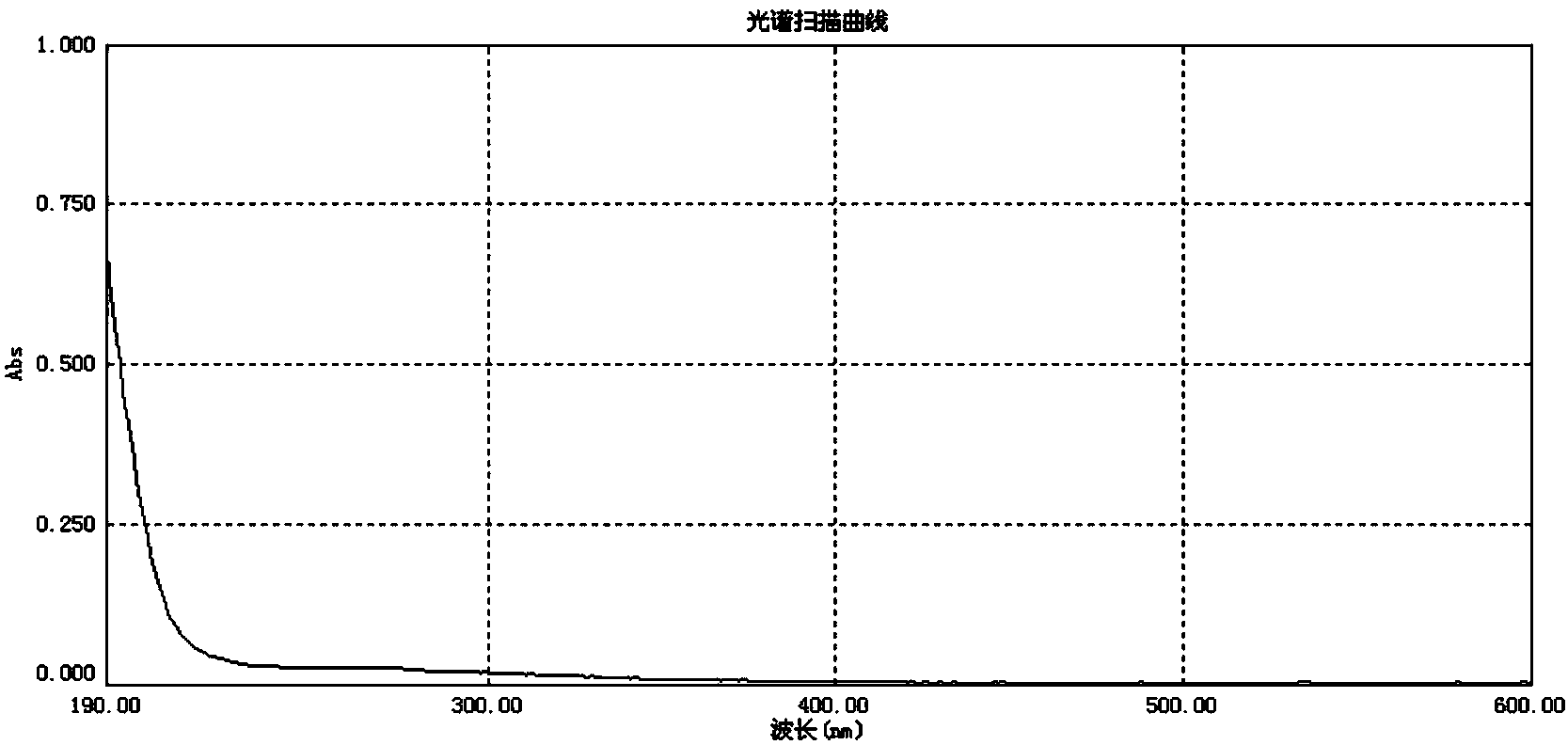

[0035] 3. Weigh 2.190g of sodium selenite and dissolve it in distilled water, set the volume to 1L, containing 1g·L-1 of selenium, and obtain the selenium standard stock solution;

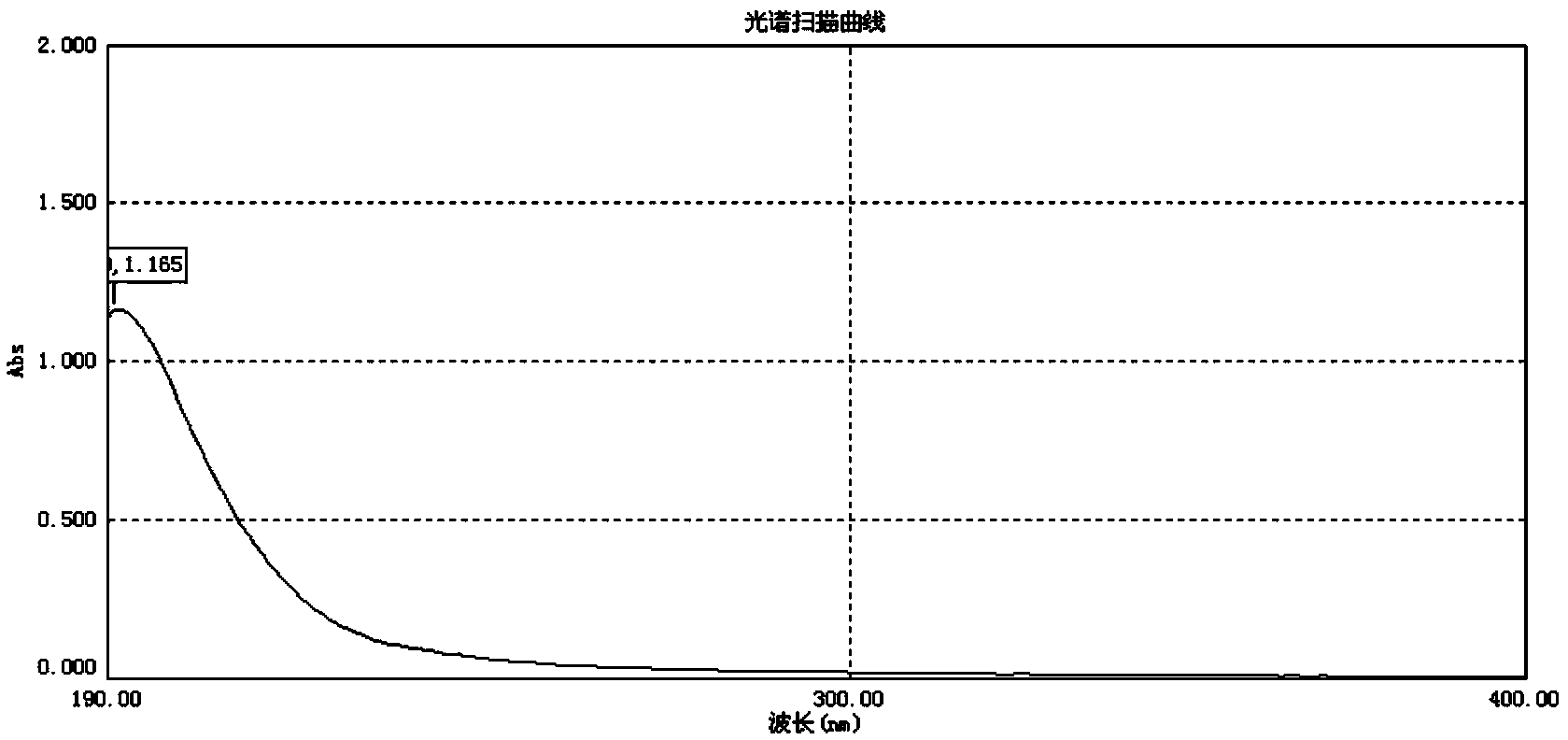

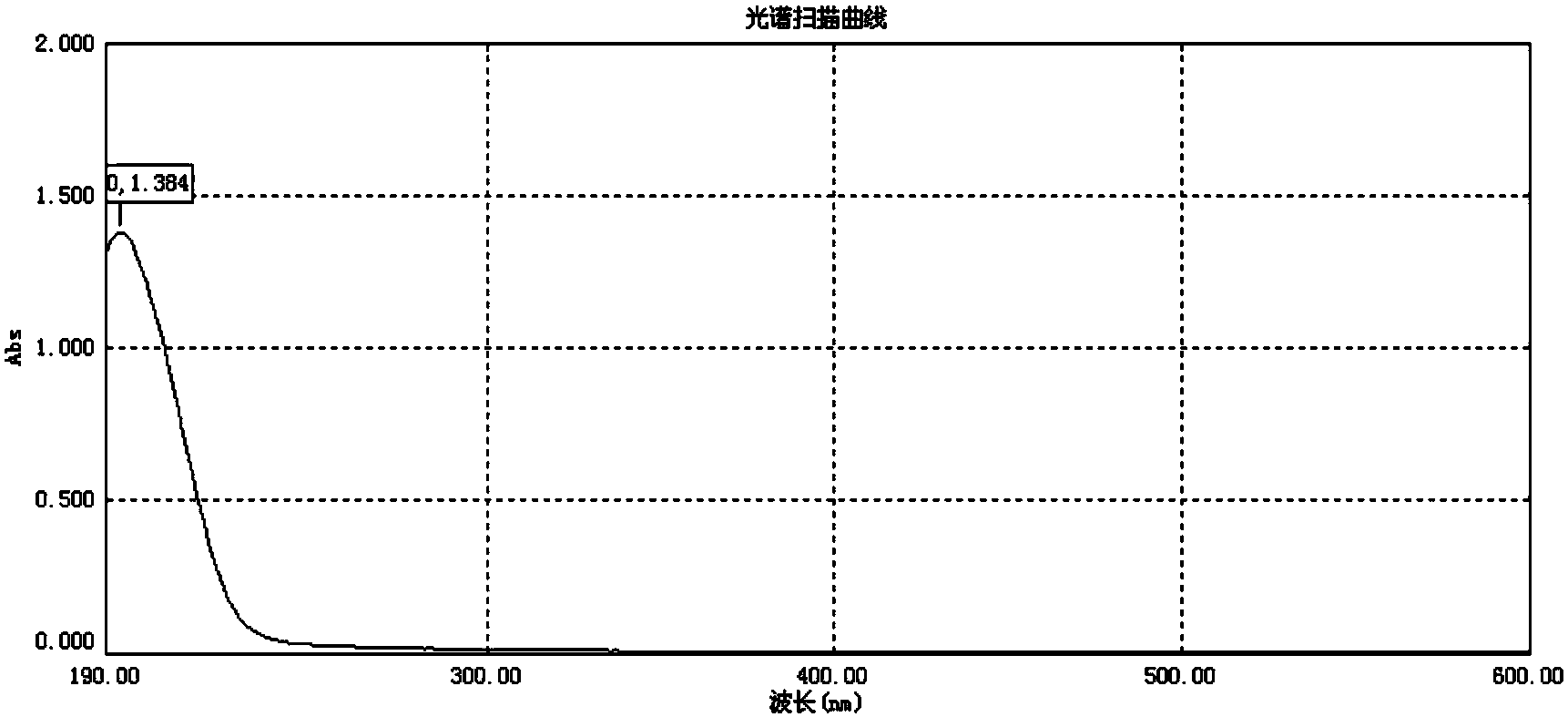

[0036] 4. Synthesis of chitosan sulfate: According to the reaction system of 3.0g chitosan and 60ml sulfonating reagent, mix evenly, react for 1h at 60°C, 100r min-1, the reactant turns brown, pour into 5 times In water and ethanol, place it at 20°C for 2 hours to form a crude chitosan sulfate; the precipitate is vacuum filtered, washed twice with ethanol, and then dried at 60°C; the yield of the prepared chitosan sulfate i...

Embodiment 2

[0039] 1. Add 100ml of dimethylformamide to a three-neck flask with a stirring device, add 30ml of chlorosulfonic acid dropwise in an ice bath, and stir at room temperature for 30min after the addition is complete to obtain a sulfonation reagent;

[0040] 2. Mix 3.5ml of dichloroacetic acid and 50ml of formamide, add 3g of chitosan and stir for 2 hours to obtain a chitosan solution;

[0041] 3. Weigh 2.190g of sodium selenite and dissolve it in distilled water, set the volume to 1L, containing 1g·L-1 of selenium, and obtain the selenium standard stock solution;

[0042] 4. Synthesis of chitosan sulfate: Mix 3.0g of chitosan and 60ml of sulfonating reagent evenly in the reaction system, react at 60°C, 100r min-1 for 1h, the reactant turns brown, pour 5 times In absolute ethanol, place at 20°C for 2 hours to form a crude chitosan sulfate; the precipitate is vacuum filtered, washed twice with ethanol, and the product is dried at 60°C; the yield of the prepared chitosan sulfate is...

Embodiment 3

[0049] 1. Add 100ml of dimethylformamide to a three-neck flask with a stirring device, add 30ml of chlorosulfonic acid dropwise in an ice bath, and stir at room temperature for 30min after the addition is complete to obtain a sulfonation reagent;

[0050] 2. Mix 3.5ml of dichloroacetic acid and 50ml of formamide, add 3g of chitosan and stir for 1 hour to obtain a chitosan solution;

[0051] 3. Weigh 2.190g of sodium selenite and dissolve it in distilled water, set the volume to 1L, containing 1g·L-1 of selenium, and obtain the selenium standard stock solution;

[0052] 4. Synthesis of chitosan sulfate: Mix 3.0g of chitosan and 60ml of sulfonating reagent evenly in the reaction system, react at 60°C, 120r min-1 for 2h, the reactant turns brown, pour 5 times In absolute ethanol, place at 20°C for 2 hours to form a crude chitosan sulfate; the precipitate is suction-filtered, washed twice with ethanol, and the product is dried at 60°C; the yield of the prepared chitosan sulfate is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com